BLUE M

Model ESP400 Industrial Oven

Page 25

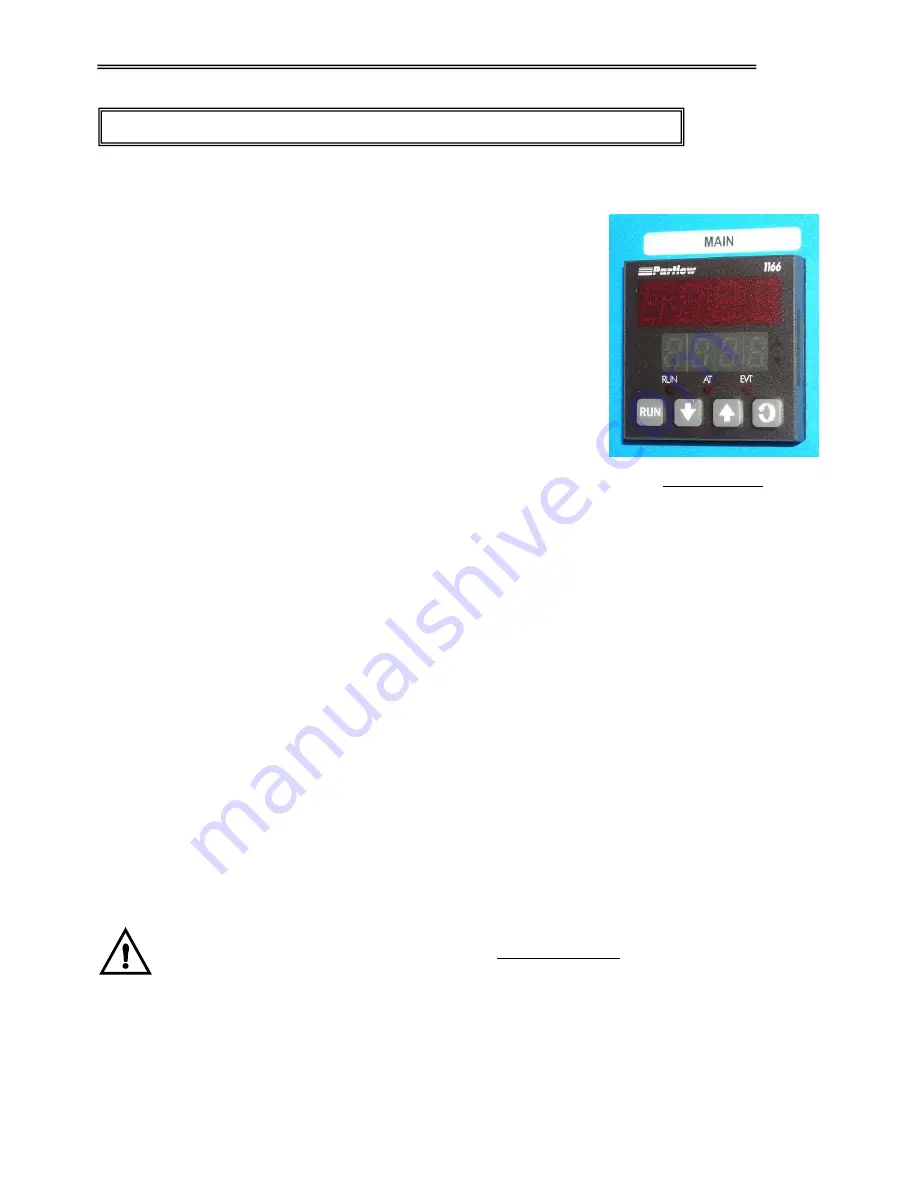

9.1 Controller

Features

Temperature control may be achieved with the alternate Partlow Model

1166 Controller. The 1166 is a profiling type, 1/16 DIN controller with the

following main features. The Type J thermocouple used for temperature

sensing is placed in the airflow at the top of the workspace.

Single

Channel

Auto/ Manual Control

1 Universal Input: Type J Thermocouple

Programs: Four with up to 16 free-form steps in each

1 Control Output: 0 - 10 VDC Time Proportioned

2 Alarm Outputs: Triac and Relay

Communications: Optional for RS-485 w/ Modbus / RTU

Data Communications:

As an option, RS-485 serial data communications may be provided with Modbus / RTU protocol. RS-485

type communications is briefly described below.

RS-485: This interface uses only 2 wires. Both wires are used for transmitting and receiving data, and

therefore, only one device may talk at a time. Up to 10 chambers may be connected to your computer on a

multi-drop network up to 4,000 feet long. Data signals are measured as a plus or minus 5 Volt differential.

9.2 Temperature

Control

Temperature control with the Partlow 1166 is achieved with a 0 - 10 VDC time proportioned output. Output 1

will energize a solid state relay, which provides power to the heater stack. The heater must be enabled by

the output of the Overtemperature Controller.

9.3

Controller Parameter Setup

The pre-programmed controller configuration for your oven is documented in the Controller Parameter Setup

Chart, which is part of your Test Report. This is located in the Supplemental Instructions Section.

Important!

The configuration set-up is mainly provided for your reference. Not all of the

parameters shown apply to your chamber. Changes to some of the set-up parameters may

drastically affect your chamber performance and void your warranty. Contact the TPS Service

Dept. before attempting any changes.

PARTLOW 1166

9.0

ALTERNATE TEMPERATURE CONTROLLER - Partlow 1166