Assembly Instructions | ILM-E Servo Kits

19

Edition 10/2021 EN

Assembly

—

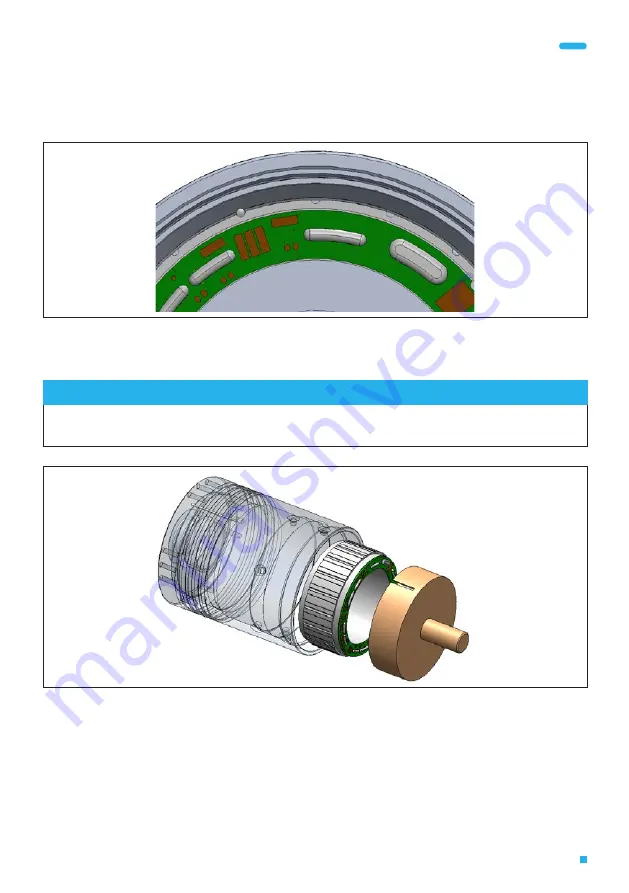

Remove the housing from the oven and align the stator in the housing as shown in

the design guidelines.

Fig. 7: Stator alignment

◀

Dowel pin

—

Use the press-in tool to carefully press the stator into the housing until the pole

cap/base of the stator touches the bottom surface of the housing.

NOTE

Make sure that the alignment/positioning of the stator does not change when it is pressed in.

Be careful not to press on the PCB while pressing the stator in.

Fig. 8: Pressing-in process