17 |

7.4

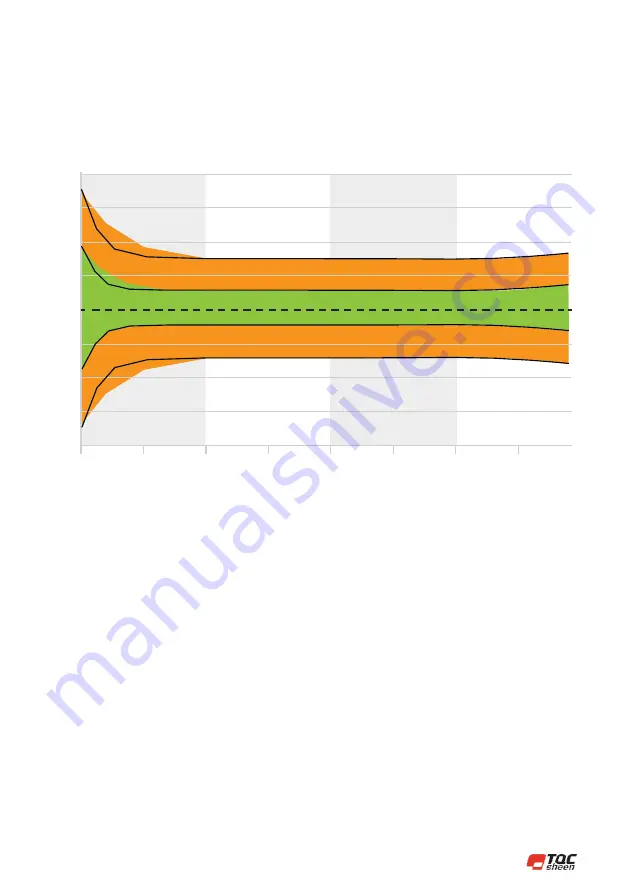

CurveX4 Logger operation measurement

ºC

+8

+6

+4

+2

0

-2

-4

-6

-8

-200ºC

1200ºC

The above-stated graphic depicts the total

maximum difference between loggers in the total

population of the loggers. This graphic is thus an

absolute worst-case scenario.

The green zone shows the worst-case performance

at standard environmental conditions.

The orange part is its full-designed temperature

use. Meaning the maximum deviation between

2 loggers measuring -200°C at an operational

temperature of 65°C is 7°C. The daily performance

of the loggers will be significantly better than the

above stated.

-10 - | +65ºC

25 ± 5ºC

-10 - | +65ºC