| 6

7 |

The PowderTAG is a photo-thermal gauge which

measures film thickness non -contact and non-

destructive. It complies with standard: DIN EN

15042-2. The small and robust instrument is suitable

for fast and precise coating thickness measurement

of powder coatings on metallic substrates before

and after cure. The measurement system consists

of a sensor and a display device. The sensor is

connected to the display device with a cable.

Please note that the performance-, range- and

accuracy of the PowderTAG is depending on the

structure and specific colour of the powder coating.

The majority of powder coatings can be measured

without any problems. In rare occasions the

coating is not compatible with the photo thermal

technology or special settings are required.

Special settings always relate to a specific powder

from a specific manufacturer and NOT to a specific

colour.

Because heat disturbs the photo-thermal

measuring principle, the measurement object

needs to be cooled down to approx 40°C when the

measurement is performed.

1.1 Information on the instructions

This manual allows for the safe and efficient use of

the instrument. The manual is part of a measuring

instrument and must at all times be kept accessible

and nearby the gauge for the staff.

The personnel must have read and understood

this manual carefully before starting work. Basic

requirement for safe working is the observance of

all specified safety and handling instructions in this

manual.

Moreover, the local work safety regulations and

general safety regulations for the application of the

PowderTAG shall apply.

Illustrations in this manual are provided for basic

understanding and may differ from the actual

design.

1.2 Safety

All warnings must be read and observed in order

to work safely and securely with the gauge. Never

make the warning labels on the instrument

unrecognizable. Keep these instructions in a safe

place and pass them with the instrument.

Observe the detailed safety instructions in section 2!

1.3 Copyright

The copyright of this operating manual remains

with TQC Sheen.

This operating manual is intended solely for the user

and his personnel. Its instructions and guidelines

may not be duplicated, circulated or otherwise

passed on to others, neither fully, nor partly.

Infringement of these restrictions may lead to legal

action may be taken if this restrictions are infringed

upon.

1.4 Manufacturer’s / supplier’s address

TQC Sheen B.V.

Molenbaan 19

2908 LL Capelle aan den IJssel

The Netherlands,

T +31(0)10-79 00 10 0

1 INTRODUCTION

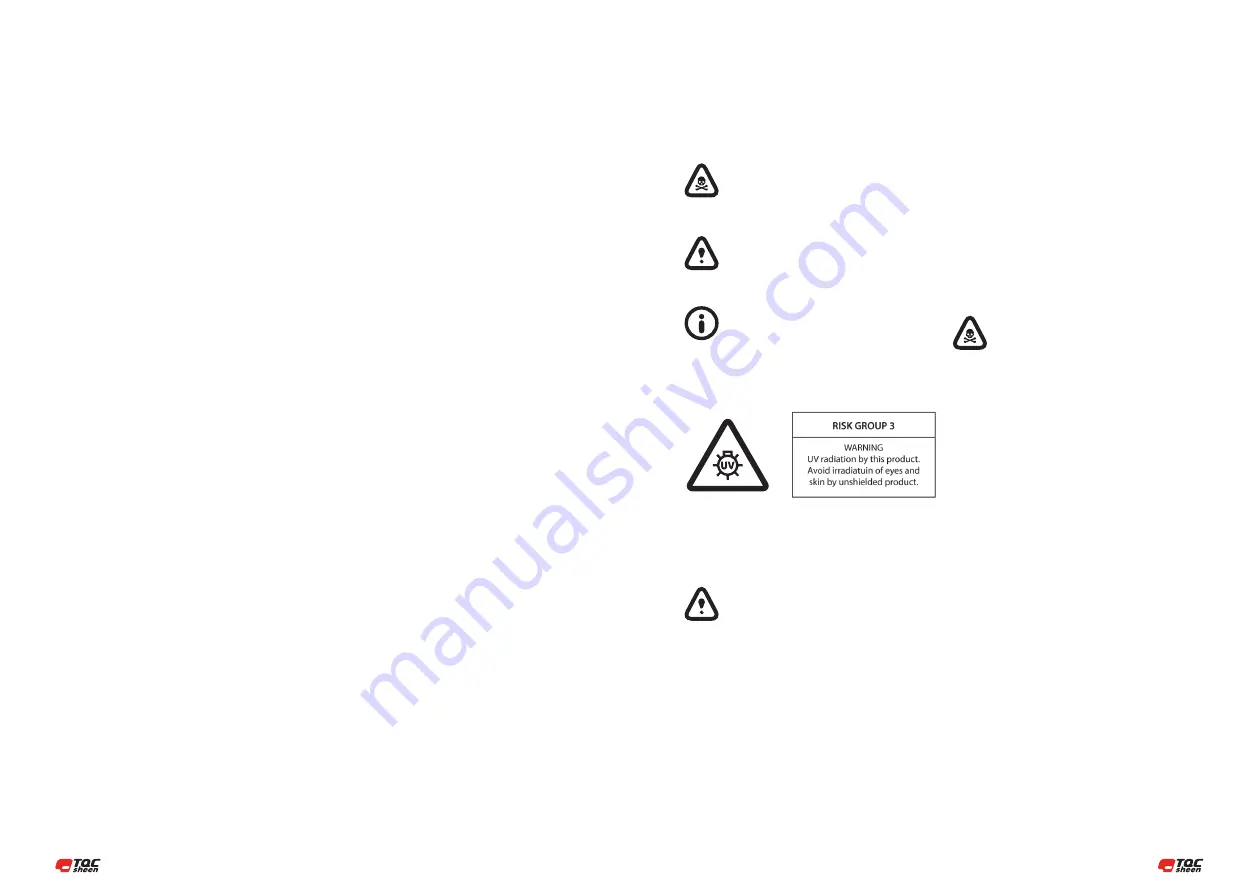

2.1 Manual symbols

The following symbols for dangers are used in this

instruction manual.

2.2 Instrument symbols

WARNING! Danger of illegible signs!

Over time stickers and signs can become dirty

or unrecognizable in any other way, so that risks

are not recognized and necessary operating

instructions are not followed. This may result in

injury. All safety, warning and operating instructions

should be kept clearly legible. Replace damaged

signs or labels immediately.

2.3 Designated purpose

The photo-thermal meter “PowderTAG” is

exclusively designed to determine the thickness of

wet and dry organic coatings for quality assurance

and production-related testing in the laboratory

environment as described within the specifications.

Other applications will be considered improper

use. TQC Sheen will not be held liable for damage

resulting from improper use. Designated purpose

also includes proper observing all instructions in the

operation manual, and adhere to inspection and

maintenance schedules.

WARNING! Misuse of PowderTAG can lead to

dangerous situations.

• Never Use PowderTAG for medical purposes.

• Never immerse PowderTAG in liquids.

Possible immediate danger to the

life or health of personnel.

If this guideline is not noted it can lead

to severe danger to health, up to fatal

injury.

A dangerous situation could be

caused.

Non observance of this guideline

can lead to injury or to damage to

equipment.

Special tips and particular

information.

Guidelines to make optimal use of the

instrument.

2 SAFETY INSTRUCTIONS

Position:

On the sensor

Position:

On the back of the equipment

Summary of Contents for LD5860

Page 13: ...www tqcsheen com ...