SP8E Log Splitter

SP8E/0612

Page 19

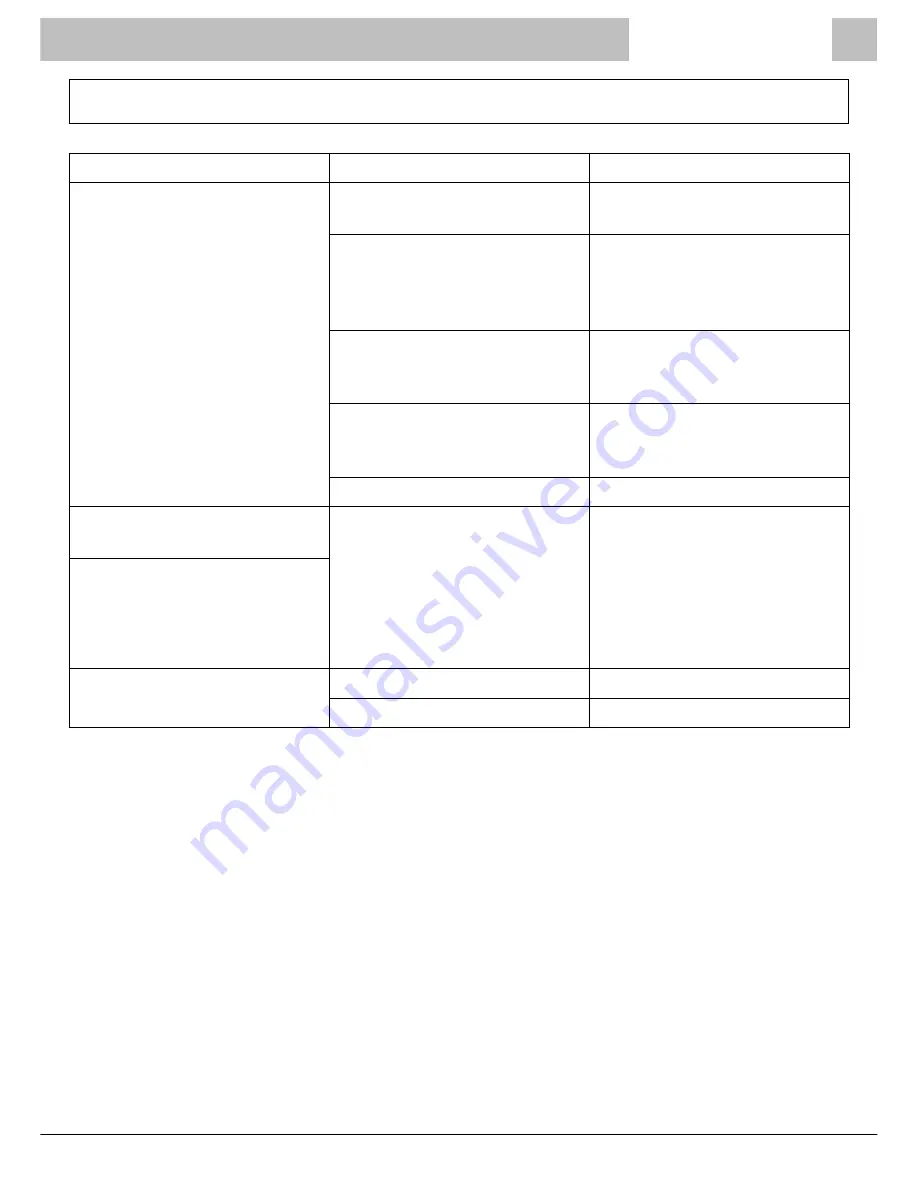

Problem

Probable Cause

Corrective Action

Log fails to split.

Incorrect positioning of the

log.

Change the position of the log

in relation to the wedge.

Log exceeds permitted

dimensions or the wood is too

hard for the capacity of the

machine.

Try to cut a small part or use

other means to reduce the

size of the log.

Wedge does not cut.

Sharped the wedge, check

IRUEXUUVRUQLFNV¿OH£I

necessary.

Oil leak.

Locate the leak using a piece

of card or wood. Contact your

dealer.

Hydraulic pressure too low.

Contact your dealer.

Rod advances jerkily or with

strong vibrations.

Air in the circuit.

Check oil level. Top up if

necessary. Check that the

connections are not restricted

or the pipes damaged in the

system from the tank to the

pump. If problem persists

contact your dealer.

Foamy oil comes out from the

¿OOHUFDS

Oil leak from the unions,

pump or cylinder.

Unions not tightened.

Tighten unions.

Seals worn.

Contact your dealer.

Resetting of the thermal cut-out motor

In the case of machines with electric motor, a protection device applied to the motor and integrated

in the main on/off switch is tripped in the case of overloads, sudden increases in voltage or accidental

faults in the electrical system. In this case, before calling your supplier, wait a few minutes and then

try to reset the main on/off switch. If the problem does not re-occur, the Log Splitter can be used

normally. If the cut-out is tripped again, do not try to reset it and contact your supplier.

Troubleshooting