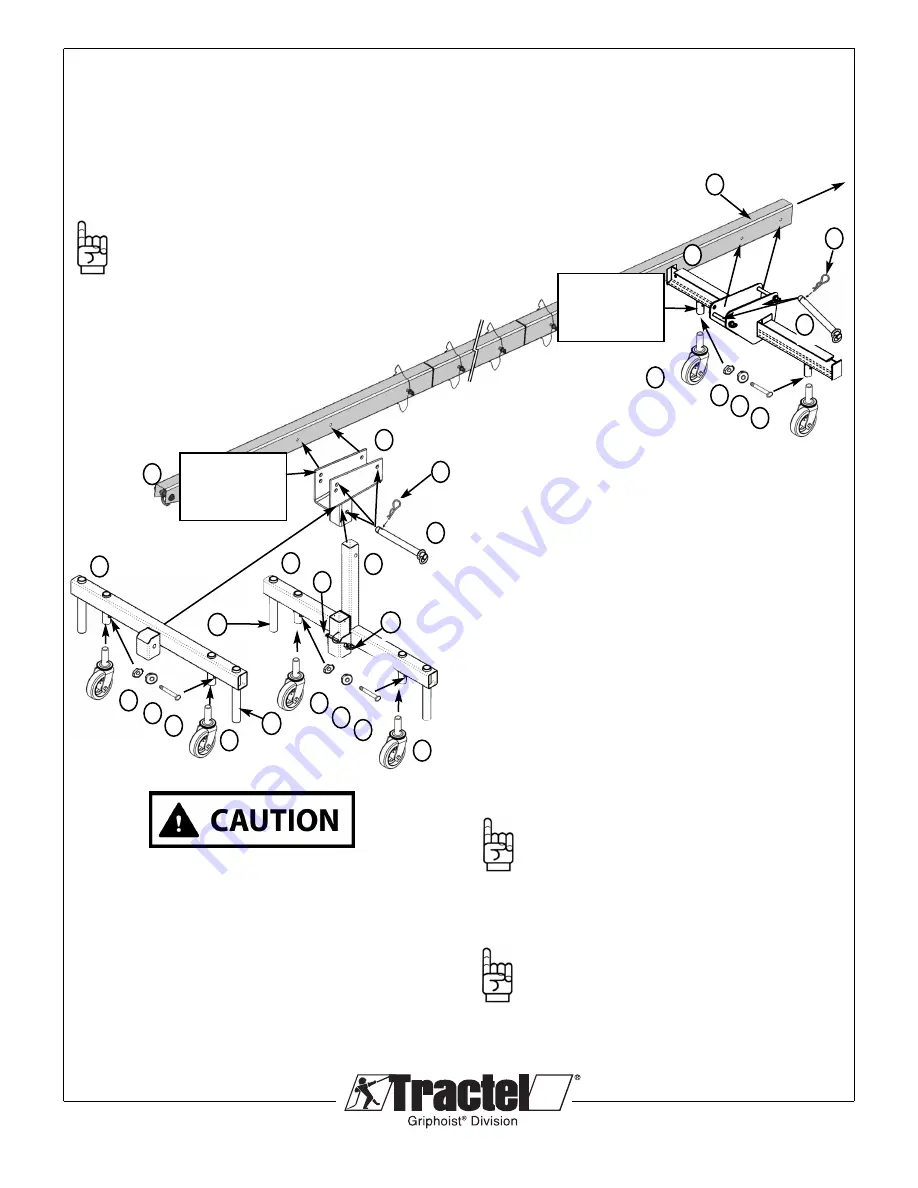

4.4

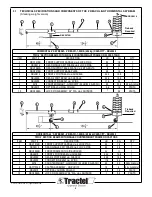

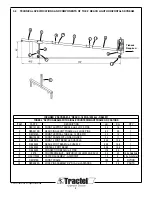

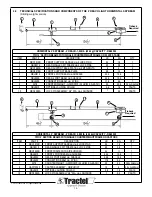

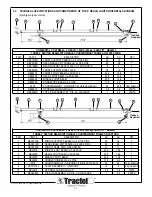

CONTINUED - ASSEMBLY OF 4 ROOF BEAM -

ADJUSTABLE STAND

(RBI101016A & RBH1050B)

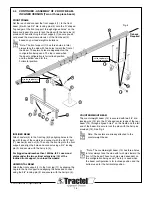

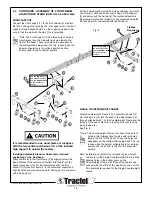

FRONT SUPPORT

Connect the front support (1) to the Front Beam (2) with two

3/4" dia. Locking Pins (3) using the ‘U’ shaped form of the front

support, through aligned holes* on the support and beam. Be

sure to lock the pins with the Hair Pins (4) provided.

*Note: The Front Support (1) has three sets of holes in

total. Always face the side with two holes toward the

front of the beam. These two holes are dependent on

the configuration being used. The top is used when the

beam configuration is for inclined position and the

bottom used for the horizontal position.

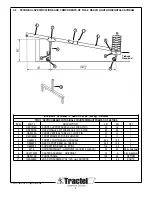

It is recommended to use wood plates or roofjacks

with the two vertical extensions (11) of the inclined

high support to unload the casters.

Installing Adjustable Stand for Horizontal or Inclined

positioning of the Roofbeam

Attach casters (5) to the Front Frame (7) by aligning holes in the

legs with those of the casters and connect with the 3/8" bolt (8),

washer (9) and nut (10). For the Horizontal position the front

support (1) into the front frame (7) in the center post support and

align the holes and connect using a 3/4” locking pin (3) and secure

with the hair pin (4).

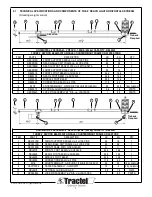

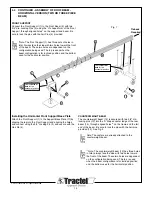

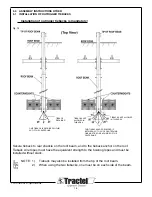

SINGLE COUNTERWEIGHT FRAMES

Single Counterweight Frame (13) is secured with two 3/4"

dia. Locking Pins (3) into the back of the Rear Beam (14),

through aligned holes** on the Counterweight Frame and the

tail end of the beam. Be sure to lock the pins with the hair

pins provided (4).

See Fig. 8.

**Note: The Counterweight Frames (13) have three sets of

holes in total. Always face the side with two holes

toward the front of the beam. These two holes are

dependent on the configuration being used. The top

is used when the beam configuration is for inclined

position and the bottom is used for the horizontal

position.

Note: Installation of casters if not already in place. Attach

casters (5) to the Single Counterweight Frame (13) by

aligning holes in the bottom posts on the

Counterweight Frame with those of the casters and

connect with the 3/8" bolt (8), washer (9) and nut (10).

Two casters are required for the Single Counterweight

Frame.

© 2012 Tractel Ltd. All Rights Reserved.

16

2

9

5

1

8

7

14

4

3

10

13

3

4

Fig. 8.

10

9

8

Use the

top hole

for

the inclined position

and the

bottom hole

for the horizontal

position.

Use the

top hole

for

the inclined position

and the

bottom hole

for the horizontal

position.

5

9

8

10

11

11

7

6

5

3

4

For the inclined position install the inclined extension (6) into the

front frame (7) as shown and connect using a 3/4” locking pin

(3) and secure with the hair pin (4). The inclined extension is

then inserted into the front support (1) and connected using the

3/4” locking pin (3) and secured with the hair pin (4).

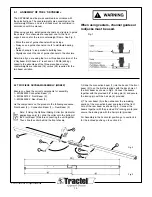

Tieback

Required