© 2013 Tractel Ltd. All Rights Reserved.

22

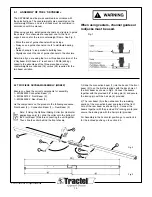

6. CHECKS BEFORE USING THE SKYBEAM

Before using on a new site, make an overall site survey, of

every place where an obstacle or dangerous items,

(I.E. electrical equipment or lines) may be located in the

possible way of the platform or of the suspension system.

Before using the platform, the following checks must be

carried out by a Competent Person.

Ensure that the load does not exceed the

rated load of the platform, hoist or rigging.

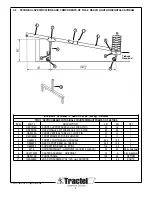

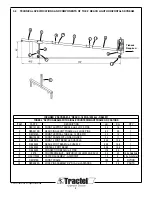

If you are using the two beam version of the

4’ skybeam 28 counterweights are required.

The three beam version requires 16

counterweights. Both beams have a 4’ reach

and a 1,000lb (454 kg). Maximum capacity.

6.1 Suspension points and support equipment

a. Check that all connectors, pins, nuts and bolts are

securely installed and fastened and that the skybeam is

structurally intact.

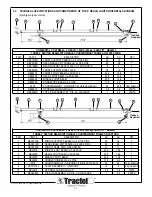

b. Check security of skybeam and ensure that the required

number of counterweights are safely fitted and locked in

place. (See Fig. 12 & 13 on page 15).

c. Ensure the safety tiebacks are installed without slack. See

section 5.0 Fig. 14 & 15 on pages 16 & 17.

d. Check that suspension points of wire ropes used with

each platform have been properly attached.

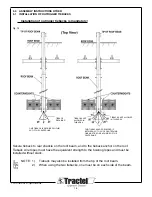

e. Ensure that the skybeam is directly above the hoist of the

platform in order to avoid excessive lateral forces side

loading on the support equipment.

(See Fig. 17 – page 19).

6.2 Tiebacks - ARE MANDATORY!

Tieback wire ropes with strength equivalent to the hoisting

ropes must be installed without slack. Tiebacks are to be at

right angles to the building and firmly secured to separate

safety tieback anchors, which meet or exceed load

capabilities of all local safety codes. In the event that the

tieback cannot be installed at right angles, See section 5.0

Fig. 14 & 15 on pages 16 & 17.

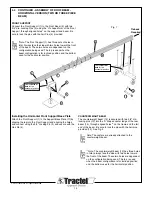

6.3 Platform

a. Refer to the manual of the platform manufacturer.

b. Check that all connectors, pins, nuts and bolts are

securely installed and fastened.

c. Check the mounting connections of the hoists.

d. Ensure that the platform is structurally intact.

e. Ensure that the load does not exceed the rated load of the

platform, hoist or skybeam.

f. Ensure that the platform is clear of any snow, ice, debris or

other material.

g. Ensure that guardrails are secured at proper height.

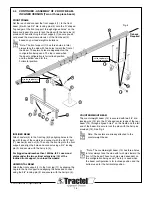

6.4 Wire ropes

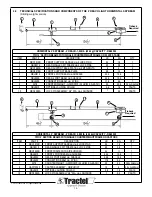

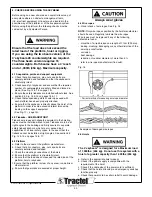

a. Visual check of wire ropes. See Fig. 18

NOTE:

Only wire ropes specified by the hoist manufacturer

should be used. Regularly lubricate the wire ropes.

Wire ropes must be replaced if any of the following

defects are found:

- more than 7 wires broken on a length of 1 foot (300 mm).

- kinking, crushing, birdcaging or any other distortion of the

wire rope construction.

- corrosion.

- heat damage.

- reduction of nominal diameter of more than 5%.

- refer to wire rope manufacturer if in doubt.

Fig. 18

-

Examples of damaged wire ropes

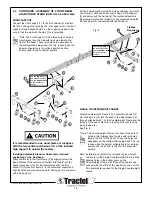

6.5 Hoists

The 4’ skybeam

®

is designed for a Maximum load

of 1,000lbs. (454 kg). Do not use this system with a

hoist of a greater capacity then 1,000lbs (454 kg).

a. Refer to the appropriate hoist manual.

b. Check if the power supply is compatible with the

requirement of the hoist.

c. Check if the cable size of the power cord is sufficient.

d. Check that the hoists, Blocstop

®

and emergency switches

function properly.

e. Check that power cord has strain relief to avoid damage.

- Correct method of measuring wire rope diameter

Always wear gloves