Installation and operating manual

G961.1 - 03/2012

EN-27

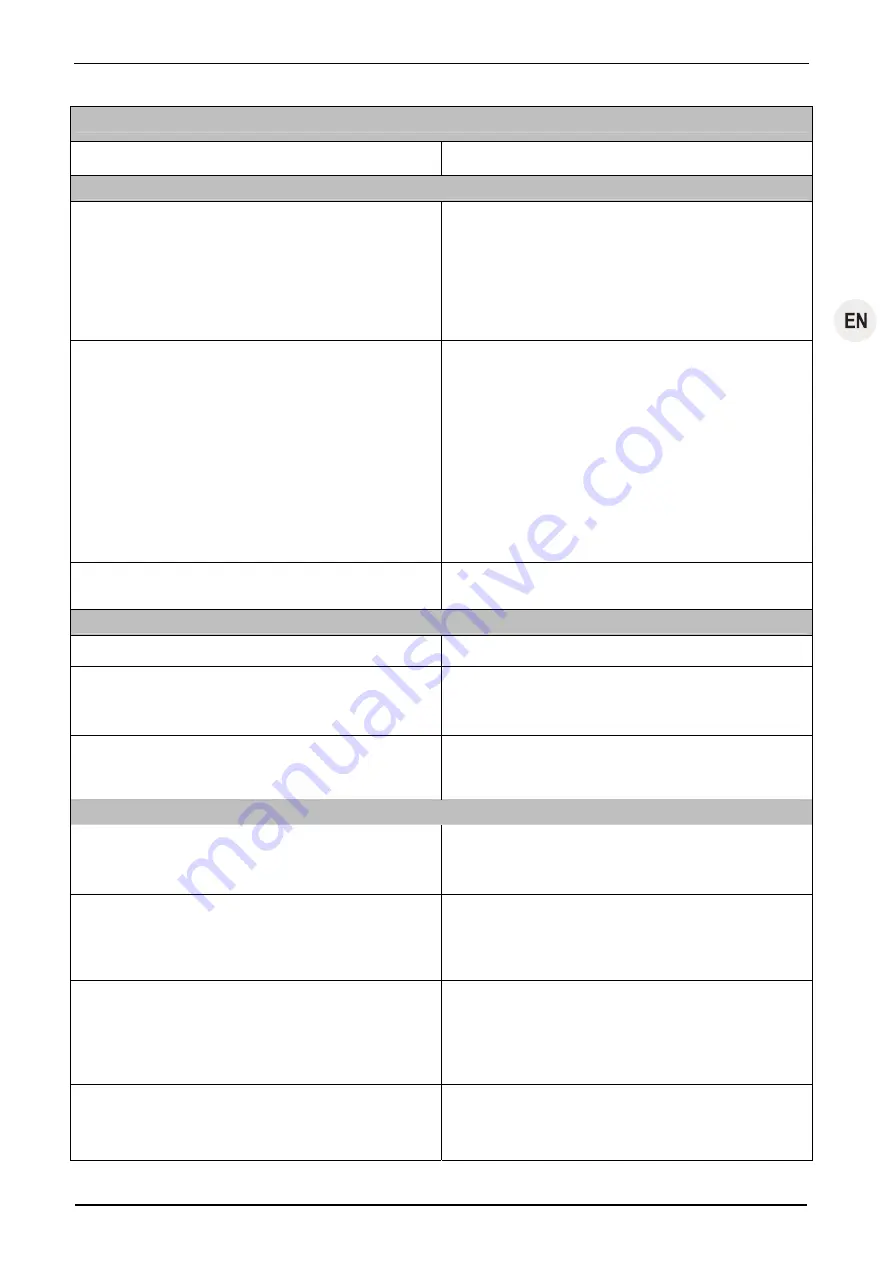

Fault

Cause

Elimination

The load cannot be lifted / pulled although the rope can be lowered / slackened.

The load has jammed on an obstacle.

–

Carefully move the load downwards and remove the obstacle.

–

Check the rope, rigging and lifting equipment to confirm their operat-

ing safety.

Overload.

–

Check the load and reduce if necessary.

–

Reeve the rope according to the block and tackle principle, see

Fig. 9.

The rope has run out of the hoist completely after lowering or slackening

without a load.

–

Feed the rope back in.

–

Clarify the cause.

–

Avoid repeating, e.g. by using a longer rope.

Fault in the UP control circuit of the hoist.

–

Have the connections, wiring and cut-outs checked by an electrician

and repair if necessary.

Limit switch UP faulty or tripped.

–

Move down until the limit switch is free.

–

Check the limit switch and replace if necessary.

Poor motor performance due to a defective starter capacitor (single phase

motor).

–

Have the starter capacitor checked by an electrician and replace if

necessary.

Defective centrifugal switch (start capacitor overloaded, single phase

motor).

–

Measure the current on the auxiliary winding in the terminal box.

Repairs should only be carried out by TRACTEL Greifzug GmbH.

The motor hums intensively or the rope drive creaks although UP and DOWN travel is possible.

Overheating caused by deficient motor cooling.

–

Provide sufficient cooling.

Overheating due to the voltage being too high or too low.

–

Have an electrician measure the voltage and power consumption

when subjected to load.

–

Increase the wire cross-section if necessary.

ATTENTION! Dirt in the rope drive.

Rope and rope drive might be damaged.

–

Replace the hoist as soon as possible and have the hoist checked /

repaired by TRACTEL Greifzug GmbH or an authorized hoisting

gear workshop.

The load cannot be lowered / slackened although the rope can be lifted / pulled.

The load has come to rest on an obstacle or has jammed on an obstacle. –

Carefully move the load upwards and remove the obstacle.

–

Check the rope, rigging and lifting equipment to confirm their operat-

ing safety.

Fault in the DOWN control circuit of the hoist.

–

Trigger emergency descent by releasing the brake, see '10.5 Emer-

gency descent' on page 18.

–

Have the connections, wiring and cut-outs checked by an electrician

and repair if necessary.

SAFETY-STOP: The secondary brake holds the rope. Possible causes:

Hoist malfunction.

Hoist speed set too high.

The secondary brake activation speed is set too low.

–

See '10.3 Secondary brake actuation' on page 18.

–

Change the hoist and the secondary brake if the cause is unclear

and return them for inspection.

Free reeler (impact drum):

Rope end switch (limit switch DOWN) has been triggered.

–

Feed the wire rope in until the rope end switch is released.

–

Determine the cause.

–

Avoid reoccurrence, e.g. by using a longer rope.

Summary of Contents for Tirak MWX 1020

Page 5: ...MWX 500 1537 G961 1 03 2012 EN DE FR NL V Fig Abb Fig Afb 1 ...

Page 12: ...MWX 500 1537 EN DE FR NL XII G961 1 03 2012 ...

Page 42: ...Installation and operating manual EN 30 G961 1 03 2012 ...

Page 133: ......

Page 134: ......

Page 135: ......

Page 136: ...G961 1 03 2012 105110 EN DE FR NL TRACTEL Greifzug GmbH ...