10

B.2 Setting the rated load

Attach rated load (e. g. 500 kg) and lift the

nominal load from ground.

Turn lower regulator to the left as far as the

stop.

Press UP button – the hoist must stop immedi-

ately.

Following each stopping o

f the hoist during

this setting procedure,

press the DOWN button

shortly

so that the upward travel is again possi-

ble.

Step by step

– turn the lower regulator slightly to the right,

– then press UP button,

until lifting of the suspended nominal load is

possible.

Important note for TIRAK

®

with 2 speeds

(pole changing motor):

The control system contains 2 load limiting

devices, the setting must be carried out for

both speeds.

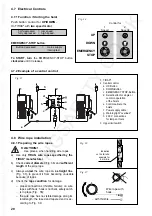

3.8.4.2 Mechanical load limiting device

The load limiting device is installed in the rope drive

and switches off the UPWARD travel in the event of

overload.

A warning signal (lamp/buzzer) is triggered which

does not go off until the cause of the overload has

been removed.

Possible causes for the switching off:

–

overload of the suspended access equipment,

possibly as a result of unfavourable load distribu-

tion

or

–

the suspended access equipment being blocked

by an obstacle during upward travel

Action following switching off:

–

reduce load to such an extent that, or redistribute

it until there is no longer any overload,

or

–

move downwards until the suspended access

equipment is free from the obstacle which must

be removed before travel is continued.

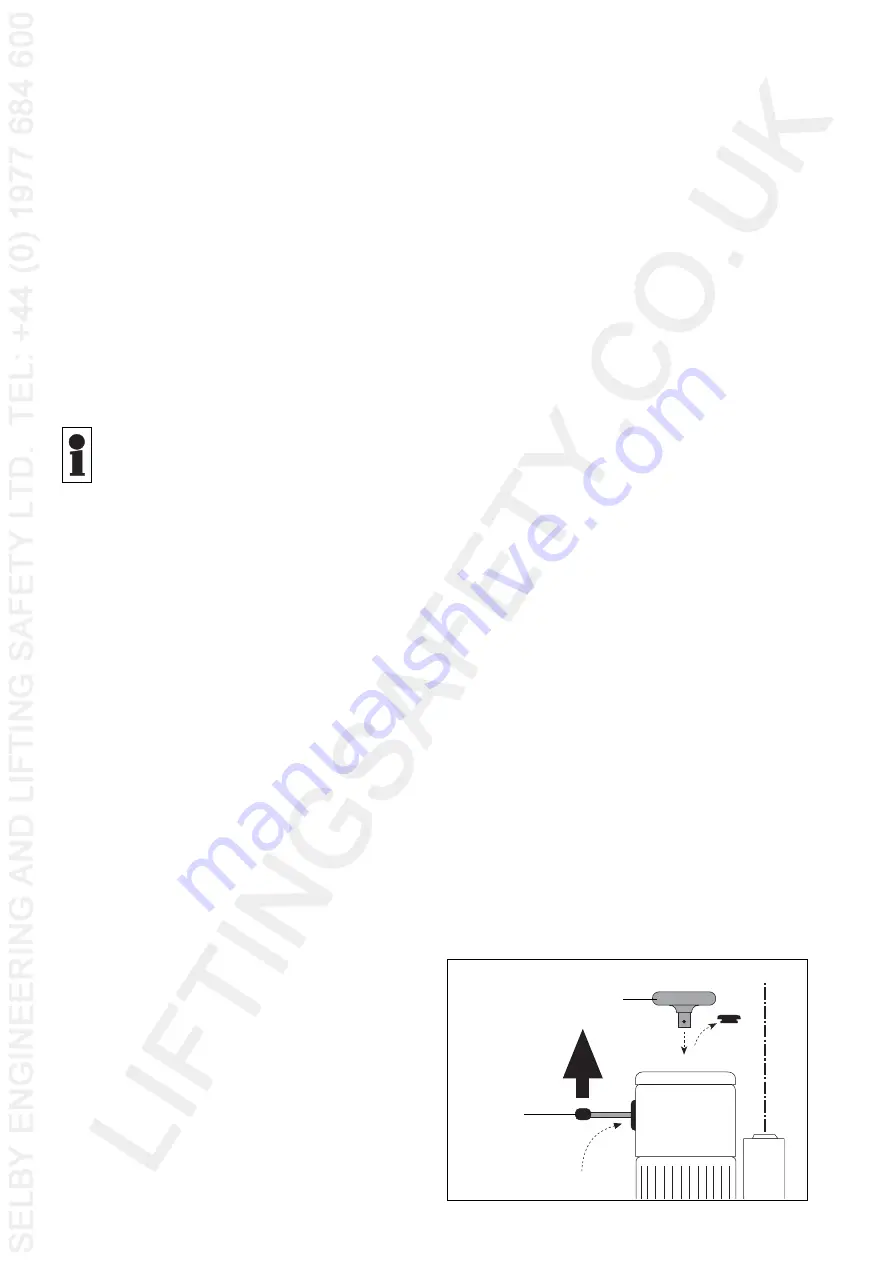

2

1

Fig. 8

3.8.5 Manual operation

Details in chapter 5.5 on page 25.

3.8.5.1 Emergency Descent

In case of power failure you can manually open

the brake with lever (1) (Fig. 8).

3.8.5.2 Manual lifting

With the brake opened the suspended ac-

cess equipment can be lifted with the hand

wheel (2) placed on the motor shaft. (Fig. 8).

3.8.6 Fall arrest devices

Suspended access equipment must be equipped with

a fall arrest device which secures the load against

falling using a safety rope.

The two systems available from the manufacturer of

the TIRAK

®

hoists are described below.

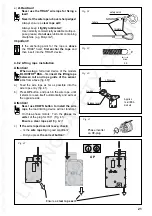

3.8.6.1 BLOCSTOP

®

Model BSA

The fall arrest device model BLOCSTOP

®

BSA is

opened by the loaded lifting rope (fig. 9) and secures

the suspended access equipment against:

a)

rupture of the lifting rope,

b)

failure of the hoist,

c)

interlocking/becoming caught during downward

travel with the result that the lifting rope is no

longer under tension,

d)

inclined position of more than the maximum ad-

missible 14

(on suspended platforms with the

two hoists attached at the ends).

3.8.6.2 BLOCSTOP

®

model BSO

The fall arrest device model BLOCSTOP

®

BSO is

released manually (fig. 10).

The speed of the safety rope is constantly monitored

and the clamping mechanism closed automatically in

the event of a sudden occurrence of excessive speed.

As a result, the suspended access equipment is se-

cured against

a)

rupture of the lifting rope and

b)

failure of the hoist

By pressing the EMERGENCY STOP button the fall

arrest device can also be closed manually in an emer-

gency. This offers the advantage that a defective

hoist can be replaced on the hanging man-riding de-

vice.

The viewing window serves to enable to check the

operation of the centrifugal weights during service.

See section 5.6 on page 25 for action in the event

of operation of the fall arrest device.