11

3.8.7 Upper limit switch

For each TIRAK

®

hoist a limit switch must be assem-

bled at the upper end of the support frame/support

stirrup of the suspended access equipment which

stops operation of upward travel when pressed

(fig. 11).

Fig. 11

lifting

rope

Rope anchor

Upper limit

switch

Limit switch

buffer plate

3.9

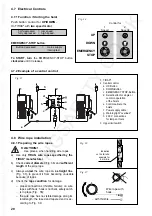

Residual risks

CAUTION!

The following risks are not constructively

covered for the TIRAK

®

hoist and the

BLOCSTOP

®

fall arrest devices:

a)

The load limiting device is set to the maximum

rated capacity of the respective hoist; the manu-

facturer of the suspended access equipment must

check whether the admissible overall weight of

his installation (own working load) cor-

responds to this value.

Should a lower value be necessary,

– have electronic load limiting device set by

qualified personnel;

(see section 3.8.4 load limiting device)

– have mechanical load limiting device set by

the manufacturer.

b)

The electronic load limiting device only de-

tects an overload during lifting/upward travel.

Therefore special care must be given to the dis-

tribution of the loads.

c)

The BLOCSTOP

®

fall arrest devices only fulfil

their safety function if the safety rope between

rope anchor and BLOCSTOP

®

is tensioned (no

slack rope!).

Therefore on safety ropes hanging down loosely,

a counterweight must always be secured 20 cm

above the ground (see 4.8.3).

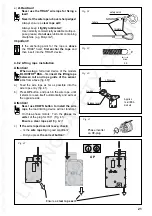

a

loaded

lifting rope

safety rope

slack

lifting rope

Cases

a) to c)

Fig. 9

Platform in

excessively

inclined

position

Case d)

Fig. 10

STOP

AUF

EMERGENCY

STOP

Closed

OPEN

Window

A buffer plate must be assembled underneath the

rope anchor on the lifting rope which triggers the limit

switch. If possible the interval (a) to the rope anchor

should be 1.5 metres or more.

With projecting components attach the buffer plate

sufficiently well below the rope anchor that the sus-

pended access equipment stops in good time.

Attention! If the limit switch has been triggered,

press the DOWN button until the limit switch is

again switched free.