16

B) BLOCSTOP

®

BSO 500 und

BSO 1020/1030

(Installation dimensions on page 18)

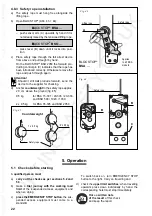

a)

The interval between safety and lifting rope is

not laid down; however it should be kept as small

as possible.

b)

Anchor the BLOCSTOP

®

device to the anchor-

ing point (A) in such a manner that the safety

rope runs vertically into the opening of the

BLOCSTOP

®

(fig. 26). If necessary guide the

safety rope over deflection pulleys.

Attention: Do not fully tighten screw; the

BLOCSTOP

®

models BSO 500 and BSO

1020/1030 must be capable of swivelling

around the anchoring point (A).

STOP

AUF

STOP

AUF

Fig. 26

A

90

90

BSO 1020/1030

BSO 500

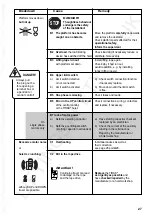

Fig. 25

Swivel

anchoring

not permitted!

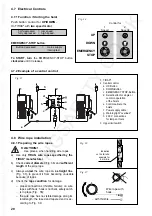

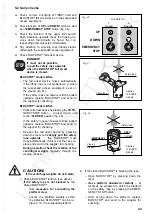

4.4.3 Anchoring the fall arrest device

A) BLOCSTOP

®

BSA …

–

Anchor the BLOCSTOP

®

Device to both anchor

points (A) in such a manner (fig. 24) that there is

10 cm interval (S) BSA 15/20… or

20 cm interval (S) BSA 35-305

between safety rope and lifting rope

(fig. 21 to 23).

–

The component to which the BLOCSSTOP

®

type

BSA... is anchored must be connected rigidly to

the suspended access equipment.

Otherwise the BLOCSTOP

®

cannot function as

an inclination limiting device (fig. 25).

Attention!

Protect BLOCSTOP

®

devices against dirt!

(Details see page 17).

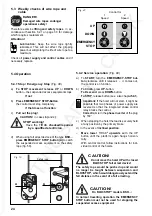

Anchoring devices

BSA 15-301 / 20-303 / 20-330:

M12x… screws, at least grade

8.8 with self-locking nuts;

BSA 35-305:

M22x… screws, at least grade

8.8 with self-locking nuts;

or bolts or similar with at least the

same strength.

Fig. 24

A

Anchoring devices

M12x… screws, at least grade 8.8

with self-locking nuts;

or bolts or similar with at least the

same strength.

Applies

to all BSA

models not

illustrated.