30

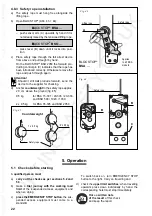

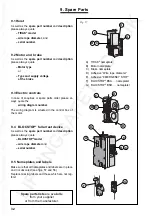

Fig. 55

c) Wire ropes

Attention!

Replace wire ropes, if one of the following

defects is determined during the prescribed

weekly check:

– 8 or more wire breaks (fig. 54) on a length

which corresponds to 30 times the rope

diameter.

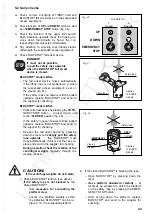

“Pig-tail” curl

in wire rope

Kinked wire rope

Damage

caused by improper use,

(e.g. by fixing a load with the rope)

Crushed wire rope

Birdcaged wire rope

Loop formation

on wire rope

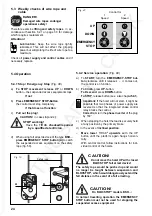

Fig. 56

Wire rope

diameter

broken wires

Fig. 54

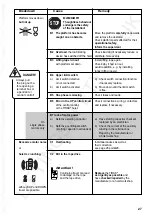

8.2

Checks

8.2.1 Essential checks

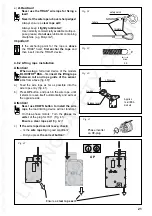

a)

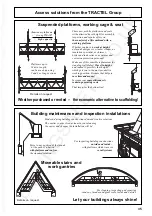

General

Prior to every operation

and

during operation make sure, that

– the TIRAK

®

hoist,

– and all other used equipment (anchoring de-

vices, pulleys etc.)

are properly installed

and

without visible damage

Attention!

If during operation damage appears:

– STOP operating,

– if necessary: cordon off the danger zone,

and

– have the damage removed by a qualified

person!

b)

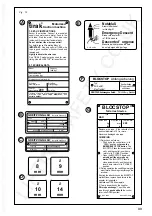

Nameplates and labels

Make sure that all nameplates and labels are in place

and not obscured (see section 9.5, pages 32 to 33).

Replace missing labels and those which are not leg-

ible!

– Heavy rust formation on the surface or in-

side.

– Heat damage, recognisable through discol-

oured wires.

– Reduction of the diameter by 5% or more

compared with the nominal diameter (fig. 56).

– External damage to the rope – fig. 55

shows the most frequent forms of damage.

These examples do not however replace the

ISO 4309 reference for wire rope checks!

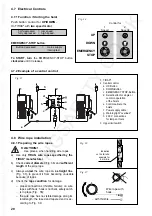

d)

Electric cables

Replace lead and control cables if damage to

the insulation or to cable connections is

determined during the prescribed weekly

check.