31

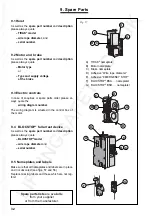

8.3 Repair

Repair of TIRAK

®

hoists must only be carried out by

the manufacturer (or Group company), or by a quali-

fied person and only original spare parts shall be

used.

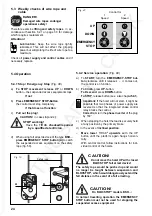

If a gearbox oil change is necessary, take one of the

oils specified below according to the temperature

range that the hoist will be usually used in.

Quantities required:

X 300/400 P series:

1,4 l

X 500-1030 P series:

2,0 l

T 1020 P series:

2,0 l

X 2050 P series:

5,0 l

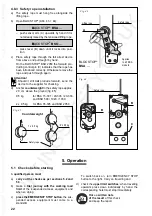

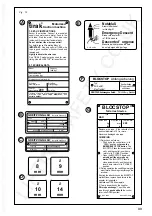

8.2.2 Safety inspection

Checking the TIRAK

®

hoists and the BLOCSTOP

®

fall arrest device by a qualified person:

1.

The TIRAK

®

should be thoroughly examined every

twelve months or more regularly (see 2 below)

depending on the working practice and current

safety regulations in force.

2.

The TIRAK

®

should be thoroughly examined at

the latest after 500 running hours but for hoists

with 18 m/min. and hoists of the series X 2050 P

with 12 m/min. speed after 250 running hours.

3.

Extraordinary check

Attention!

Following a fall arrest, a qualified person

must check the operational safety of the

BLOCSTOP

©

fall arrest device including an-

chor points, as well as the safety rope and

the rope anchoring.

It is the responsibility of the employer

that a written register is kept showing

the dates, period of use, and inspec-

tion record.

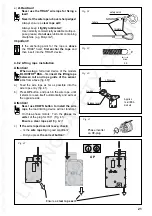

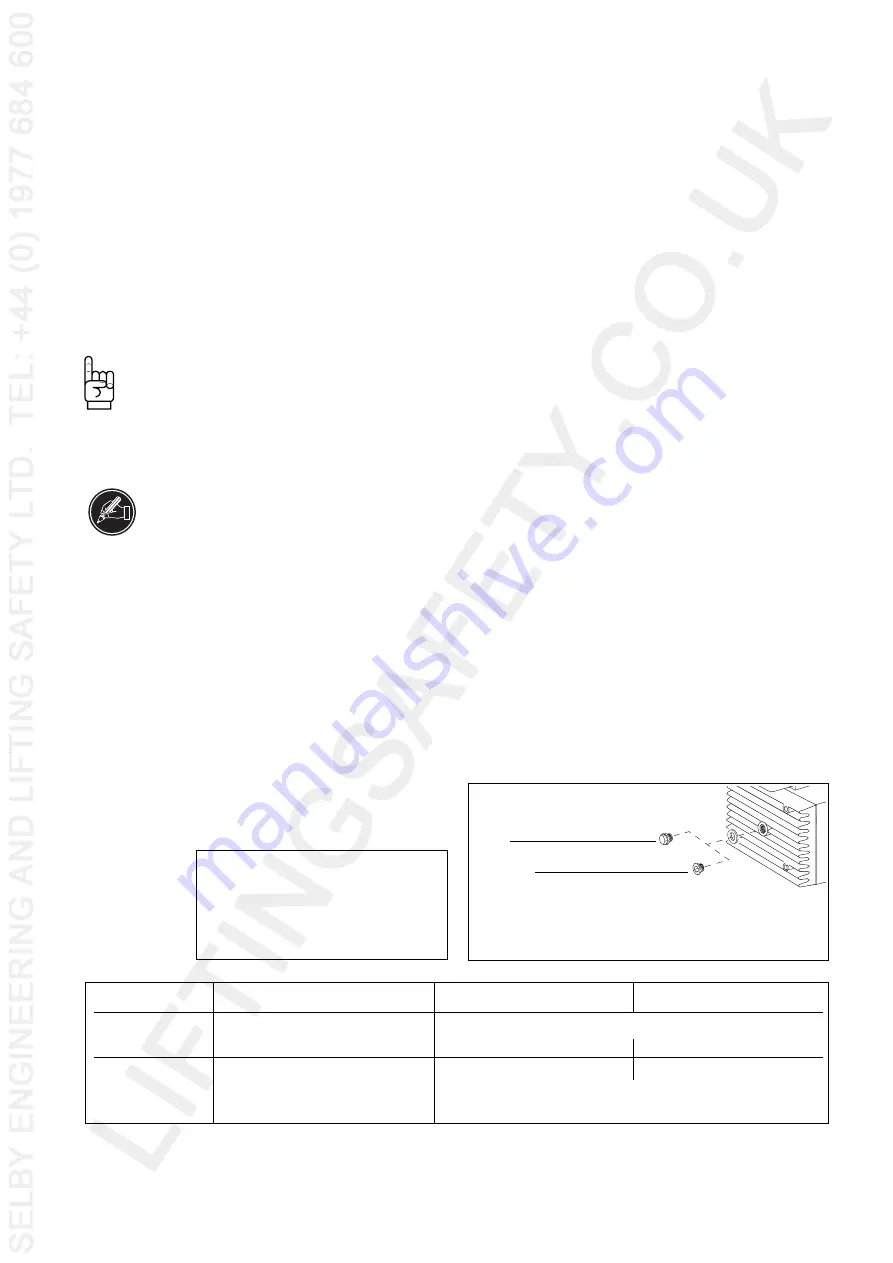

Temperature range

-10 to +50

C

-35 to +40

C

-15 to +80

C

Mineral oils

3)

Synthetic oils

3)

API Specification

SAE85W-140 GL5

1)

CLPPG or PGLP ISO VG 100

CLPPG or PGLP ISO VG 460

2)

Sample oils

BP Hypogear EP 90

Klübersynth GH6 100

Klübersynth GH6 460

(other oils

SHELL Spirax HD 90

on request)

TEXACO Multigear EP6 S80 W90

1) Standard charge on series X 300 P, X 500 to 820 P and T 1020 P; also see foot note 3)!

(Marking: Socket head cap oil drain plug, Fig. 57)

2) Standard charge on series X 400 P and X 1030 to 2050 P

(Marking: Hexagon oil drain plug, Fig. 57)

3) Important: Changing between mineral and synthetic oils requires the complete cleaning of the gearbox parts.

Applying other synthetic oils is not allowed

without official agreement by the manufacturer!

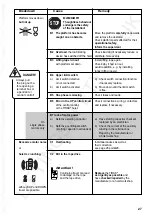

Table 8

Form of oil drain plug

indicating the applied oil

Mineral oil

Synthetic oil

Fig. 57