9

GB

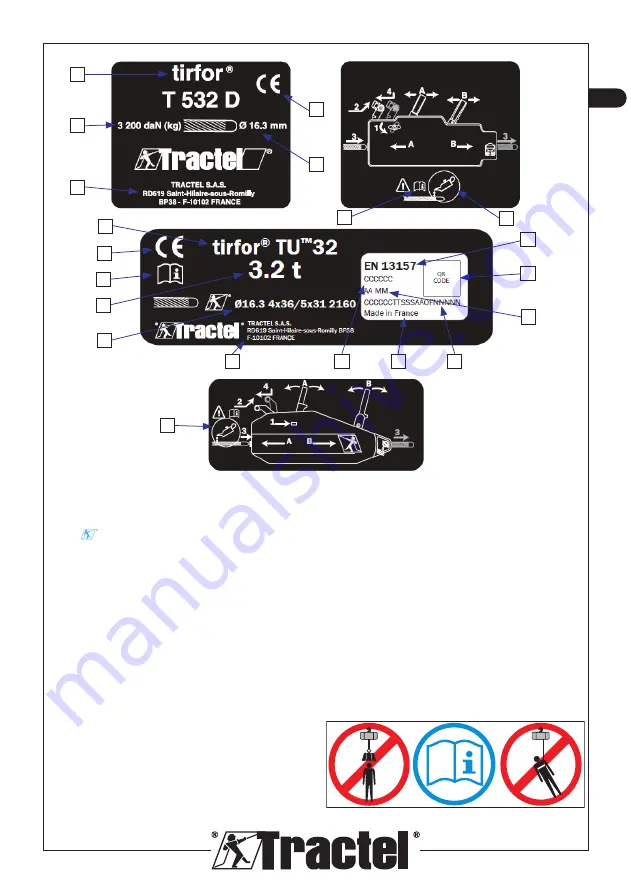

• a: Type of machine

• b: Working load limit

• c: Designation of the tirfor tirfor

®

–

: tractel

®

logo

– Ø16.3: Diameter of the wire rope

– 4x36/5x31: composition of the wire rope, i.e. 4

strands of 36 wires or 5 strands of 31 wires

– 2160: class of the wire rope in MPa

• d: CE marking

• e: Refer to the operating and maintenance instructions

• f: Manufacturer’s name and address

• g: Lubricate or grease the wire rope generously

• h: Machine complies with standard EN 13157

• i: diameter of the wire rope

• j: reference of the technical equipment

• k: YY = last two digits of the year of manufacture

MM = month of manufacture

• m: serial number of the machine

• n: barcode in two dimensions

• o: country of manufacture (France)

The numbers 1 to 4 in the diagram indicate the order in

which the operations are performed to feed the tirfor

®

wire

rope into the machine. The letters A and B in the diagram

indicate which lever should be actuated to obtain the

indicated direction of travel of the tirfor

®

wire cable.

Each T500D machine is identified by its serial No,. using

the format YY MF NNN stamped on the body of the

machine where:

– YY: the last two digits of the year of manufacture

– MF: the No. of the manufacturing file

– NNN: the No. of the machine in the manufacturing

file

Each TU

™

machine is identified by its serial No. of the

type CCCCCCTTSSSYYMFNNNNN engraved on the

machine’s rear operating lever.

15.2. Label mentioning prohibitions

to be located under the load, using

the device to lift people and obligation

to read the instruction manual and

maintenance manual

LOAD

TU

™

machines

T500D machines

a

b

e

d

i

f

e

g

a

d

b

g

c

k

f

j

o

n

h

m