--------------------------------------------------------------------------------------------------------------

TROUBLES AND REMEDIES

Trouble

Possible causes

Remedies

Motor unable to run

or running slow

⑴

Fault in line, or voltage insufficient

⑵

Power wire too thin or too long

⑶

Fault in pressure switch

⑷

Fault in motor

⑸

Sticking of main compressor

⑹

The inner thermal protector on motor cut off

⑴

Check the line

⑵

Replace the wire

⑶

Repair or replace

⑷

Repair or replace

⑸

Check and repair

⑹

Compressor works too hard; turn off

the power to cool down the motor for 10-

15 minutes.

Sticking of main

compressor

⑴

Moving parts burnt

⑵

Moving parts damaged, or stuck by foreign body

Check crankshaft, bearing, connecting

rod, piston, piston ring, etc. and replace

if necessary

Excessive vibration

or abnormal noise

⑴

Connecting part loose

⑵

Foreign body got into main compressor

⑶

Piston knocking valve seat

⑷

Moving parts seriously worn

⑴

Check and re-tighten

⑵

Check and clean away

⑶

Replace with thicker paper gasket

⑷

Repair or replace

Pressure insufficient

or discharge

capacity decreased

⑴

Motor running too slow

⑵

Air filter choked up

⑶

Leakage of safety valve

⑷

Leakage of discharge pipe

⑸

Sealing gasket damaged

⑹

Valve plate damaged, carbon build up or stuck

⑺

Piston ring and cylinder worn or damaged

⑴

Check and remedy

⑵

Clean or replace the cartridge

⑶

Check and adjust

⑷

Check and repair

⑸

Check and replace

⑹

Replace and clean

⑺

Repair or replace

Summary of Contents for MCFRC241

Page 1: ...Direct Drive Oil free Silent Air Compressor MCFRC241 242 243...

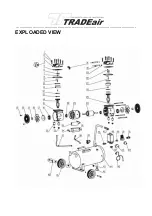

Page 11: ...EXPLOADED VIEW...

Page 13: ......