--------------------------------------------------------------------------------------------------------------

GENERAL SAFETY INSTRUCTIONS

Before attempting to operate this compressor the following basic safety precautions should

always be taken to reduce the risk of fire, electric shock and personal injury. It is important to

read the instruction manual to understand the application, limitations and potential hazards

associated with any tool. They are designed for the safety of yourself and others, ensuring a

long and trouble free service life from your machine.

Work Area

Workbenches should be kept tidy because cluttered benches and work areas invite accidents.

Floors should be kept clean and free from rubbish. Special care should be taken if the floor is

slippery due to sawdust or wax.

Work Environment

Keep the work area well lit. Do not use compressor in areas where there is a risk of explosion

or fire from combustible materials, flammable liquids, e.g., paint, varnish, petrol etc or

flammable gases and dust of an explosive nature.

Guard Against Electric Shock

Do not expose your compressor to rain, or use in damp or wet locations.

Beware Children and Pets

Children and pets should be kept out of the work area.

Use the right tool

Select the right tool for the job. Do not use a tool for a job for which it was not designed.

Do not force a small tool to do the job of a heavy-duty tool.

Personal safety Clothing

Do not wear loose clothing, jewellery or anything that could get caught in moving machinery.

Hair

Long hair should be tied back or contained in a protective covering.

Eye Protection

Always use protective safety goggles or safety glasses.

Ear Protection

Ear protection is advised during periods of extended operation.

Footwear

Where there is a risk of heavy objects damaging feet or if there is a risk of slipping on wet or

slippery floors suitable non-slip safety footwear should be worn.

Secure the Work Piece

Wherever possible secure the work piece using clamps or a vice. It is safer than using your

Summary of Contents for MCFRC241

Page 1: ...Direct Drive Oil free Silent Air Compressor MCFRC241 242 243...

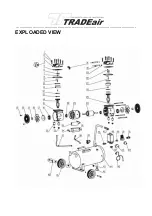

Page 11: ...EXPLOADED VIEW...

Page 13: ......