--------------------------------------------------------------------------------------------------------------

authorized service facility.

Check Damaged Parts

Before using the compressor it should be carefully checked to determine that it will operate

properly and perform its intended function. Check for the correct alignment of moving parts

ensuring they do not bind. Check for broken or missing parts and have them replaced or

repaired at an authorized service centre. Check any other condition that may affect the

operation of the compressor. A guard or any other part of the compressor that is damaged

should be properly repaired or replaced by an authorized service centre.

Disconnect Compressor

Ensure that the compressor is disconnected from the mains supply and the tank is empty

when not in use, before servicing, lubricating or making adjustments to air lines, and when

changing accessories such as blades, bits, nails and cutters on air tools.

Avoid Unintentional Starting

Ensure that the switch is in the OFF position before plugging the compressor into the

mains supply

Turning the compressor ON and OFF

Use the red knob on top of the pressure switch to turn the unit on and off. Pull the knob up

to turn the compressor on and push the knob in to turn it off. Turning the unit on and off from

the mains supply only will result in damage to the motor and void warranty as the pressure

switch has an additional function to purge the air trapped in the delivery pipe when the

motor is turned off. This minimises the load on the motor when it is next started.

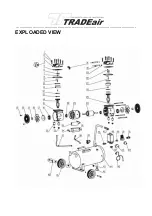

GENERAL VIEW AND MAIN COMPONENTS

1) Silent & oil-free air pump with plastic cover

Summary of Contents for MCFRC241

Page 1: ...Direct Drive Oil free Silent Air Compressor MCFRC241 242 243...

Page 11: ...EXPLOADED VIEW...

Page 13: ......