Mar-18

Product Code: 2829

Made in China to TQB Brands Pty Ltd specifications

Page 10

Visit us at www.tqbbrands.com.au

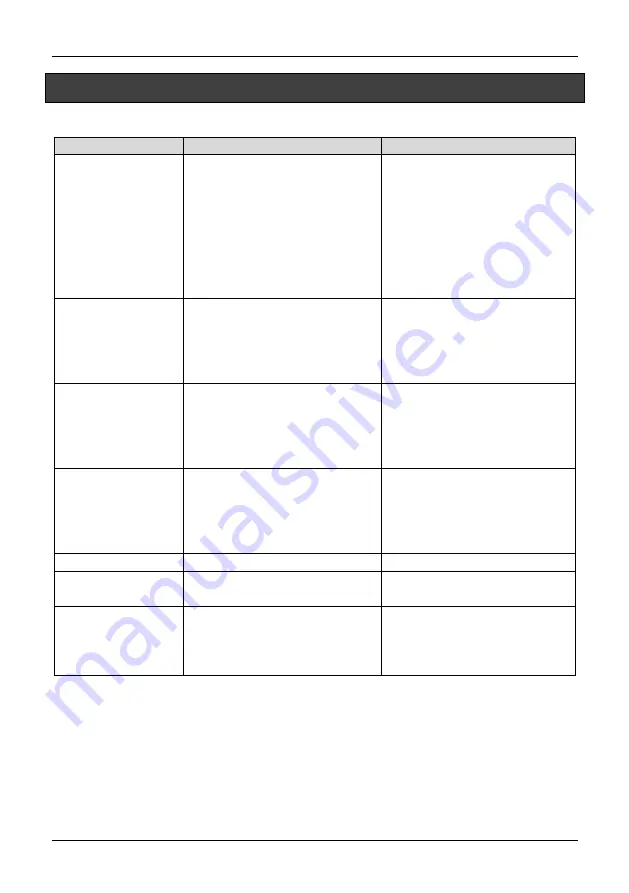

TROUBLESHOOTING

PROBLEM

POSSIBLE CAUSE

ACTION

Jack will not lift

Control valve in wrong position.

Low/no oil in reservoir.

Air-locked system.

Load is above capacity of jack.

Delivery valve and/or bypass

valve not working correctly.

Seals worn out or defective.

Turn control valve knob

clockwise.

Fill with oil and bleed system.

Bleed system.

Use correct equipment.

Clean to remove dirt or foreign

matter. Replace oil.

Install appropriate seal kit.

Jack lifts only

partially

Too much or not enough oil

Ram Piston is binding

Check oil level

Look for dirt, gummy

deposits, leaks,

misalignment, worn parts or

defective packing.

Jack advances

slowly

Low air supply pressure

Pump not working correctly

Leaking seals

Adjust air supply pressure to

90 – 145psi

Install seal kit, or replace

power unit

Install seal kit

Jack lifts load, but

doesn’t hold

Cylinder packing is leaking

Valve not working correctly

(suction, delivery, release or

bypass).

Air-locked system

Install seal kit

Inspect valves. Clean and

repair seat surfaces

Bleed system as per

instructions

Jack leaks oil

Worn or damaged seals

Install seal kit

Jack will not retract

Control valve in wrong

position

Move Control valve to

DOWN position

Jack retracts slowly

Release valve is closed

Reservoir is over full

Ram cylinder damaged

internally

Fully open release valve

Drain excess hydraulic fluid

Send jack to authorised

service centre