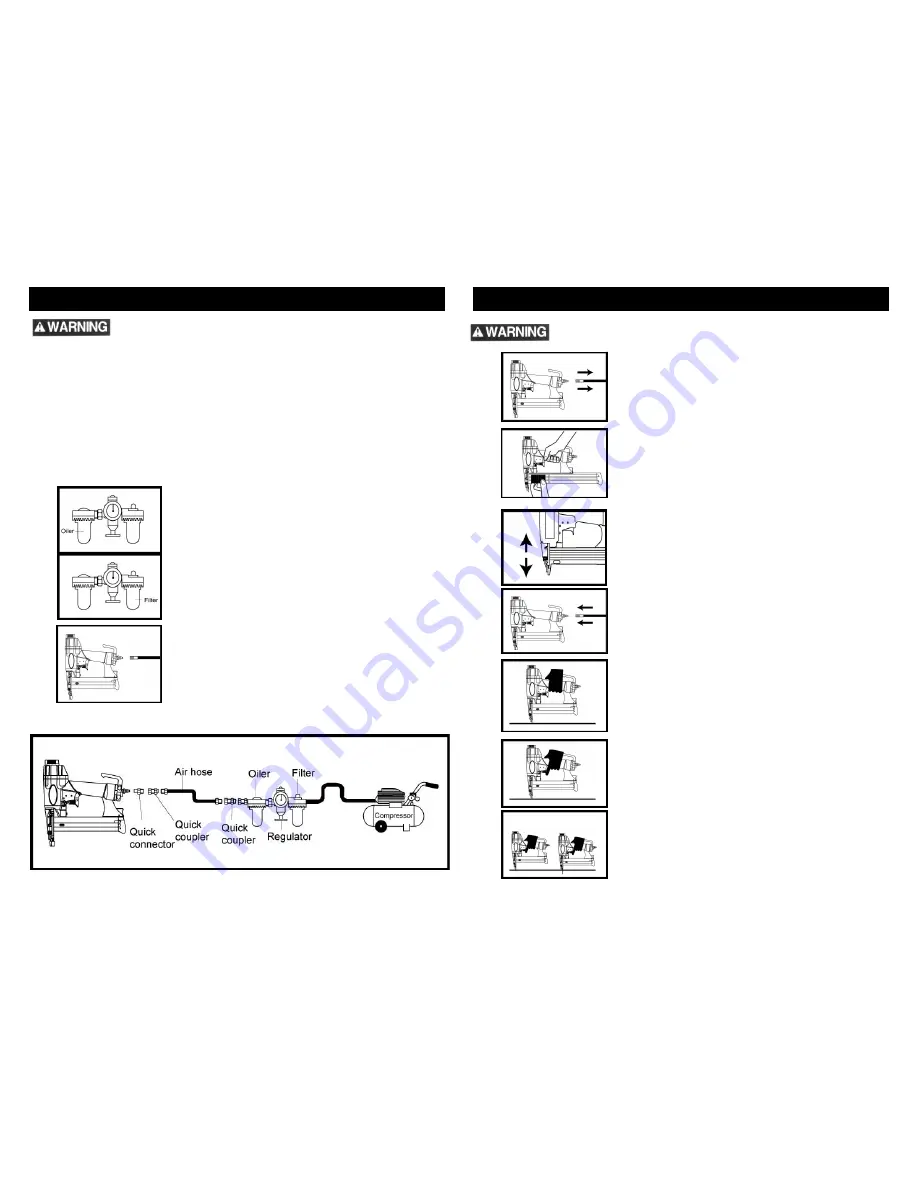

AIR SUPPLY AND CONNECTIONS

The compressed air power source shall be pressure-regulated. The regulated

pressure must not exceed the maximum air pressure marked on the tool. If a

regulator fails, the pressure delivered to the tool must not exceed 1.5 times the

maximum air pressure, or 180 PSI, whichever is greater.

Pressure regulators shall be used to limit the air pressure supplied to the tool.

Regulators shall be set at an operating pressure which is lower than or equal to the

tool manufacturer’s specified maximum air pressure.

Air supply hoses shall have a minimum working pressure rating equal to or greater

than the pressure from the power source if a regulator fails, or 120 PSI, whichever is

greater.

Tools shall be fitted with a fitting or hose coupling on or near the tool in such a manner

that all compressed air in the tool is discharged at the time the fitting or hose coupling

is disconnected.

Many air tool users find it convenient to use an

oilier to help provide oil circulation throughout

the tool and to increase the efficiency and useful

life of the tool. Check oil level in the oilier daily.

Many air tool users find it convenient to use a

filter to remove liquids and impurities which can

rust or wear internal parts of the tool. A filter can

also increase the efficiency and usefulness

of the tool. The filter must be checked on a daily

basis, and if necessary, drained.

For better performance, install a 3/8” quick

connector (1/4” NPT threads) with an inside

diameter of .315” on your tool and a 3/8” quick

coupler on the air hose.

The following illustration shows the correct mode of connection to the air supply

system which will increase the efficiency and useful life of the tool.

TESTING THE SAFETY TRIP MECHANISM

Never point any operational fastener driving tool at yourself or at any other

person.

Disconnect the air supply from the tool.

Insert a stick of fasteners into the magazine. See section

on “Loading Fasteners Into The Nailer”.

Press down on workpiece and release the contact safety

trip mechanism. Verify there is no binding, sticking or

jamming of this mechanism.

Reconnect the air supply to the tool.

Depress the contact safety trip mechanism against the

workpiece without pulling the trigger. The tool must not

cycle. Never use the tool if a cycle occurs.

Hold the tool clear of the workpiece. The contact safety trip

mechanism should return to its original down position. Pull

the trigger. The tool must not cycle. Do not use the tool if a

cycle occurs.

To complete the testing procedures, depress the contact

safety mechanism against the workpiece and pull the

trigger, the tool must cycle.

4

5

Summary of Contents for Magnesium 8510

Page 8: ...NOTES NOTES 14 15...