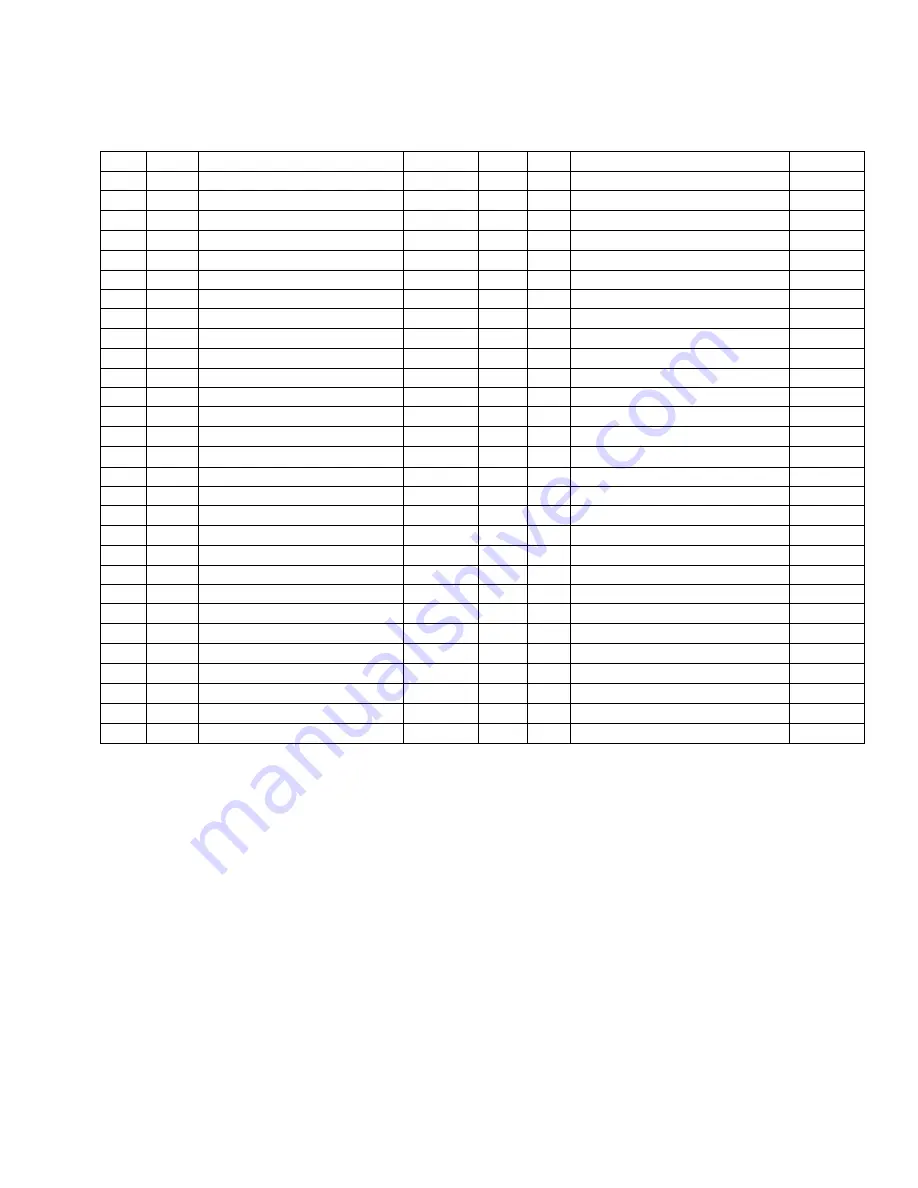

BBQ07E PARTS LIST

Item

Qty

Description

P/N

Item

Qty

Description

P/N

2

1

Grill Frame Assembly

SUB052

102

2

3” Caster W/O Brake

HDW301

K

2

Washer .300 x .600 Zinc

HDW271

104

2

Wheel Leg

FAB019

20

1

Hopper Burner Assembly

SUB110

106

2

6” Vipor Wheel

HDW300

22

1

Burner Box Assembly

SUB002

107

2

Shoulder Bolt 3/8-16 Thread

HDW131

30

1

Auger Assembly 070, 07E

SUB005

108

2

Washer 5/16 Flat Zinc

HDW120

35

1

Auger Tube Bushing

BRN109

109

2

Nut 3/8-16 Acorn

HDW132

36

1

Auger Drive Motor

BRN100

112

1

Grease Bucket

HDW152

37

1

Screw 6-32 x .750 Socket Hd

HDW116

113

1

Flue Pipe Assembly

FAB309

38

1

Nut 6-32 Nylock Zinc

HDW112

119

1

Chimney Cap Assembly Bronze

SUB150

39

1

Screw 8-32 x .375 S-tap

HDW114

126

1

Flue Pipe Gasket

INS145

40

1

Firepot Assembly

FAB310

B

2

Bolt 1/4-20 x .47 Hex Head

HDW088

46

1

Hot Rod (Ignitor)

BAC199

F

8

Washer 1/4 Flat Zinc

HDW130

47

8

Screw #8 x .5 Hex S-Tap

HDW119

A

8

Bolt 5/16-18 Socket Black

HDW005

48

1

3/8 x 3/16 Thick Gasket

BRN900

C

8

Nut 5/16-18 Hex Black

HDW006

49

1

Draft Inducer Fan Assy

FAN209

G

8

Washer 5/16 Lock Black

HDW008

50

1

Power Cord 8’ Nema 120v

ELE203

E

16

Washer 5/16 Flat Black

HDW007

51

1

Strain Relief

ELE210

J

2

Bolt 1/4-20 x .310 Hex Zinc

HDW088

61

1

Hopper Lid Assembly

SUB167

140

1

Heat Baffle

BCA012

66

2

Nut 8-32 K-Lock Zinc

HDW108

141

1

Drain Pan

BCA070

67

2

Screw 8-32 x .25 PPHD Zinc

HDW079

143

1

12” Chrome Handle

HDW227

68

4

Screw 6-32 x .375 S-Tap

HDW115

147

1

Porcelain Grill

HDW195

69

1

DIGITAL CONTROL W/SDC

BAC283

152

1

Burner Gasket

INS144

70

2

Screw 6-32 x .375 S-Tap

HDW115

153

1

Hopper Top Level Assembly

SUB177

71

1

7” RTD Sensor

BAC194

D

2

Nut 1/4-20 Hex

Hdw123

80

1

Door Assembly Bronze 07E

SUB178

91

4

Screw 8-32 x .5 PH Truss Zinc

HDW117

99

2

Caster Leg 07E, 075

FAB020

101

2

Square Leg Insert

HDW303

Summary of Contents for BBQ075.01

Page 20: ...BBQ07E COMPONENT LIST ...

Page 22: ......