5 |

P a g e

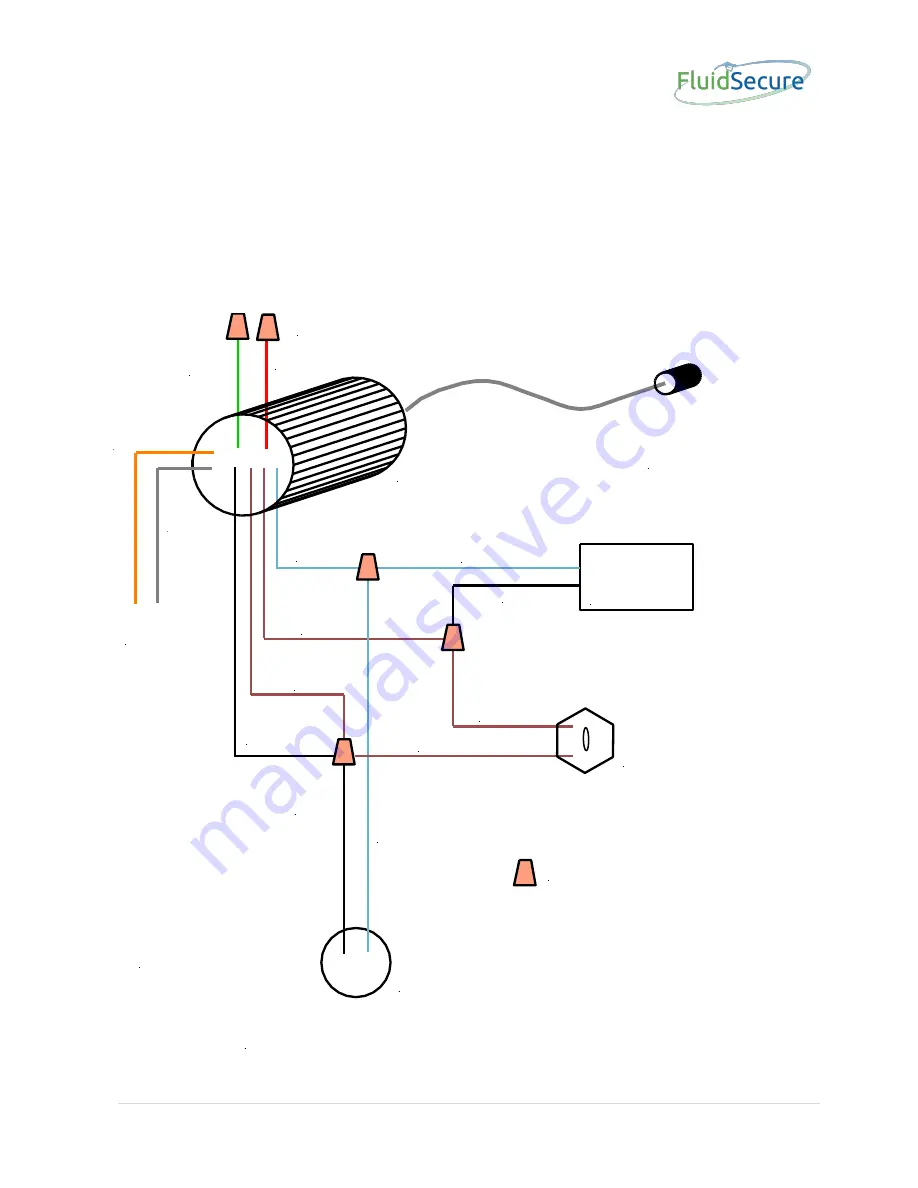

2) Wiring Connections

The installation typically involves disconnecting the AC power supply wring (generally

that comes from a nearby building or power source) from the dispenser and re-routing it

through the supplied conduit parts that are supplied as part of the LINK kit and re-

connecting the wires to the FluidSecure LINK and dispenser.

Under no condition

should a FluidSecure LINK control a pump motor larger than 3/4hp.

Larger loads

can be controlled with an external contactor or power relay.

DISPENSER

Solenoid/

Motor

MANUAL

OVERRIDE

SWITCH

FLUIDSECURE LINK

POWER

FROM

BUILDING

or Dispenser

WIRENUTS

BROWN

BROWN

BROWN

BROWN

BLACK

120VAC/

240VAC

BLACK

BLACK

WHITE

WHITE

WHITE

(Neutral)

RED

(+12VDC)

GREEN

(DC Gnd)

ORANGE

GRAY

INTERNAL

PULSER

CONNECTIONS

NOTE:

Two brown wires coming

from the FluidSecure

unit are dry contacts of

a 16 amp mechanical

relay and are not electrically

connected internally in the

FluidSecure Link

FluidSecure Link Wiring Diagram

Alternate power input to run Link from a 12VDC source

External

Link

Pulser

Connector