16

TRAK Machine Tools

Southwestern Industries, Inc.

ProtoTRAK SMX, K2, K3 & K4 & Retrofit Safety, Installation, Maintenance, Service and Parts List Manual

2.9 Cleaning

1.

Remove rust protective coating from the machine before moving any slideways (table, saddle, knee, etc.).

2.

The coating is best removed with clean, dry rags. Do not use a cleaning solution that may damage the rubber

way scrapers, plastic parts, or paint.

WARNING!

Do not use gasoline or other flammable cleaning agents for cleaning the machine.

3.

It may be necessary to move back and forward, left and right, and up and down the table, saddle and the ram. Always release the clamp

levers (two in front of the table, one underneath the saddle on each side, and two ram lockbolts on the

right side of the column) before attempting to move the above parts.

CAUTION!

Never move any of the above parts over ways that were not previously cleaned.

Serious damage to the TURCITE surface of slideways can occur.

4.

Be certain the table, saddle and spindle move freely and smoothly over their entire length.

2.10 Leveling: Leveling Tolerance is .0005”/10”

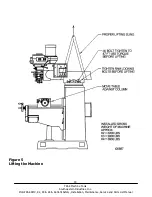

1.

Set the machine on its 4 leveling pads on a solid, level floor prepared in accordance with the state and local

rules for machine tool installation.

2.

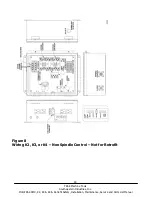

Put one or two precision Spirit Levels or Electronic Levels in the center of the table in the positions illustrated in

Figure 6.

3.

Adjust the 4 corner leveling screws on their pads until the machine is level to .0005 in/10 in.

4.

If the machine must be anchored to the floor, follow the general instruction for installing machine tools and use

for leveling any well-known methods: shims, etc.).

5.

If the machine must be installed on vibration mounts/pads (rubber, commercially available leveling and vibration

mounts, etc.) follow the instructions delivered with the mounts/pads, ordering them to satisfy the load of the

machine and the maximum weight of the work piece.

6.

When machine is correctly level, lock the adjusting screws in place with their hex nuts.