47

TRAK Machine Tools

Southwestern Industries, Inc.

ProtoTRAK SMX, K2, K3 & K4 & Retrofit Safety, Installation, Maintenance, Service and Parts List Manual

Do the following service codes and procedures:

Code 33

Software Identification. This is needed if you call SWI Customer Service.

Code 313

Configuration Values

Code 123

Calibration Mode.

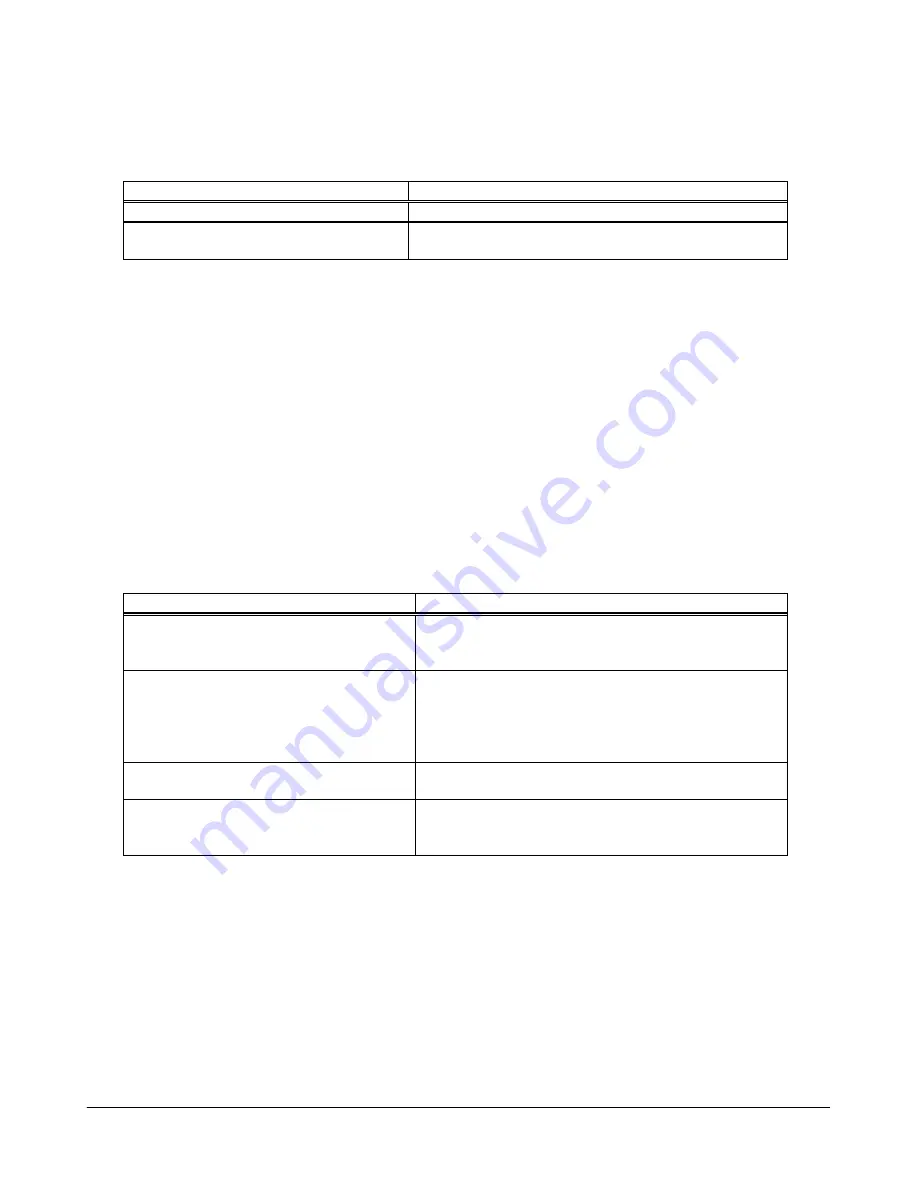

Possible Cause

Check This

Configuration file corrupt

Load default configuration by going to code 313

Not saving Calibration values

Replace Computer/Pendant module.

See Computer/Pendant

If calibration factors are being saved, but the measurements are not repeating or are not accurate:

See Measurements Are Not Repeating

See Measurements Are Not Accurate

3.3.10 Auxiliary Functions Not Working (Option on 3 Axis

Machines Only)

The Auxiliary Functions will not turn on or off at the programmed times. There are 3 Auxiliary Functions:

1.

Activates or deactivates a "110VAC Receptacle" typically used for a coolant pump or solenoid for mister.

2.

Sends an electrical signal to rotate the turret on a "Haas Indexer".

3.

Turns the "Spindle Off" at the end of a programmed event. (Note: This function is not available for retrofits.).

In order to run the above auxiliary functions in run mode, the accessory key on the front of the pendant must be in the

AUTO mode. Press and hold to activate AUTO mode.

All of the auxiliary function signals are carried down to the cable breakout box through umbilical #2. Each

function then has its own relay inside this box. If one of these relays fail then these features will not work.

Do the following service code and procedures:

Code 33

Software Identification. This is needed if you call SWI Customer Service.

Possible Cause

Check This

Bad 110VAC "Coolant or solenoid"

receptacle fuse

Check if the fuse light indicator next to the plug is lit.

Verify that the fuses are good or bad by checking the

resistance of the fuses using an Ohmmeter.

Poor cable connections

Check all the cable connections on the cable

breakout box, Coolant Pump, and Air Solenoid

(Located on the Air Regulator). In particular, check

umbilical # 2 cable, which carries the auxiliary

function signals.

Faulty "Indexer" connector

Check for continuity between pins 3 and 4, when the

output of the Haas Indexer connector is activated.

Bad cable breakout box

Check 110 V power coming out of the AC E-stop port

with the E-stop in the out position. This will cause

the spindle to not run.

3.3.11 E-Stop Error

The E-Stop turns the power off to the axis and spindle motors. This is done by stopping 110V power from

reaching the cable breakout box through the use of a relay in the pendant.

Once power reaches the cable breakout box it distributes power to the axis motors, auxiliary functions and

110V power to the spindle contactor for non-spindle control machines. If power does not reach the cable

breakout box then none of these functions will work.

Spindle Control Electrical Box

A 5-volt logic signal is sent to the spindle control board, which energizes a relay that enables the AC drive.

Non Spindle Control Electrical Box

110V Power reaches the electrical box through the AC E-stop cable. It is used to energize the spindle motor

contactor. If this contactor is not energized the spindle will not turn on. See Figure 19.