63

TRAK Machine Tools

Southwestern Industries, Inc.

ProtoTRAK SMX, K2, K3 & K4 & Retrofit Safety, Installation, Maintenance, Service and Parts List Manual

Write down the reading on the DRO.

Do not re-zero the DRO, traverse away and return several times

Write down the DRO readings

Random error

will be unpredictable and give scattered readings, adding and/or subtracting the error after each

traverse with no pattern. See Step 2.

Accumulating error

will add roughly the same amount to the reading after each traverse. See Step 3.

2.

For random error, look for problems in the set-up of the TRAK Sensor that have resulted in a loss of rigidity.

Common sources of random error include:

broken base

broken bracket

loose puller screws

loose run bar

very loose motion of the table or saddle

loose clamp screw

3.

Accumulating error is almost always the result of the wheel not traveling in a path parallel to the motion of

the axis. This causes the wheel to skip at certain regular points in its travel.

Inspect the base to determine if it has been damaged. A damaged base will usually have crinkles in the

small, triangle-shaped plates on the front and back.

Use a bubble level or an indicator to adjust the puller screws so that the base is parallel to the running

surface.

Inspect that the sensor is not cocked so that the case contacts the running surface.

Inspect the wheel for chips that are adhered or for gouges.

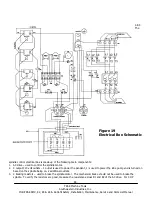

4.8 Electrical

4.8.1 Checking A/C Voltage

This procedure tests for the 115V power for the control.

Use a Voltmeter, reading A/C volts.

Acceptable range is 100V to 130V.

Note: systems running consistently close to the low values may have problems when normal voltage fluctuations push

the voltage out of the acceptable range.

Test the following in the order presented:

Problems Here:

May Indicate:

1.

The wall outlet.

Fuse blown in the shop electrical

panel.

Incoming service from local utility

is bad. Call the electric company.

2.

The control power cord from the wall.

Check the end that goes to the electrics

box.

Power cord defective.

3. Check the top fuse on the electrical cabinet.

It should be an 8-amp fuse.

If this is blown then power will not

reach the 4 outlets on the electrical

box.

3.

Check the 110-power cord to the pendant.

Power cord defective

4.8.2 Checking Fuses

CAUTION!

Turn off power before removing and replacing fuses.