71

TRAK Machine Tools

Southwestern Industries, Inc.

ProtoTRAK SMX, K2, K3 & K4 & Retrofit Safety, Installation, Maintenance, Service and Parts List Manual

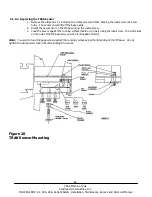

4.9.2.3 CODE 100: Axis Open Loop Test

Code 100 procedure is used to diagnose problems with the configuration of the system, the encoders and incoming A/C

voltage.

CAUTION!

During this procedure, the designated axis will be given a command to move at maximum speed for 1 second in the

direction you choose. Avoid crashes by making sure the quill is out of the way and by starting with the table and saddle

centered. MAKE SURE THAT NO ONE IS STANDING IN THE WAY OF THE TABLE OR SADDLE!

Note: You will lose the DRO reference position.

This procedure is to be run for each axis that is servo-driven, and for both the plus and minus direction for each axis.

1.

Center the table and saddle and raise the head. Make sure the gib locks are released.

2.

On the Pendant display, go into the Service Codes and input the Code 100.

3.

The conversation line will say: “SELECT AXIS”. Input the axis. Either X, Y or Z.

4.

In the conversation line it will say “WHICH DIRECTION? PLUS”.

If you want to run in the plus direction, press INC SET.

If you want to run in the minus direction, press +/-, then INC SET

5.

In the conversation line it will say “PRESS GO”. Press Go after you are sure that the machine will not crash

in the direction and axis that you have specified.

6.

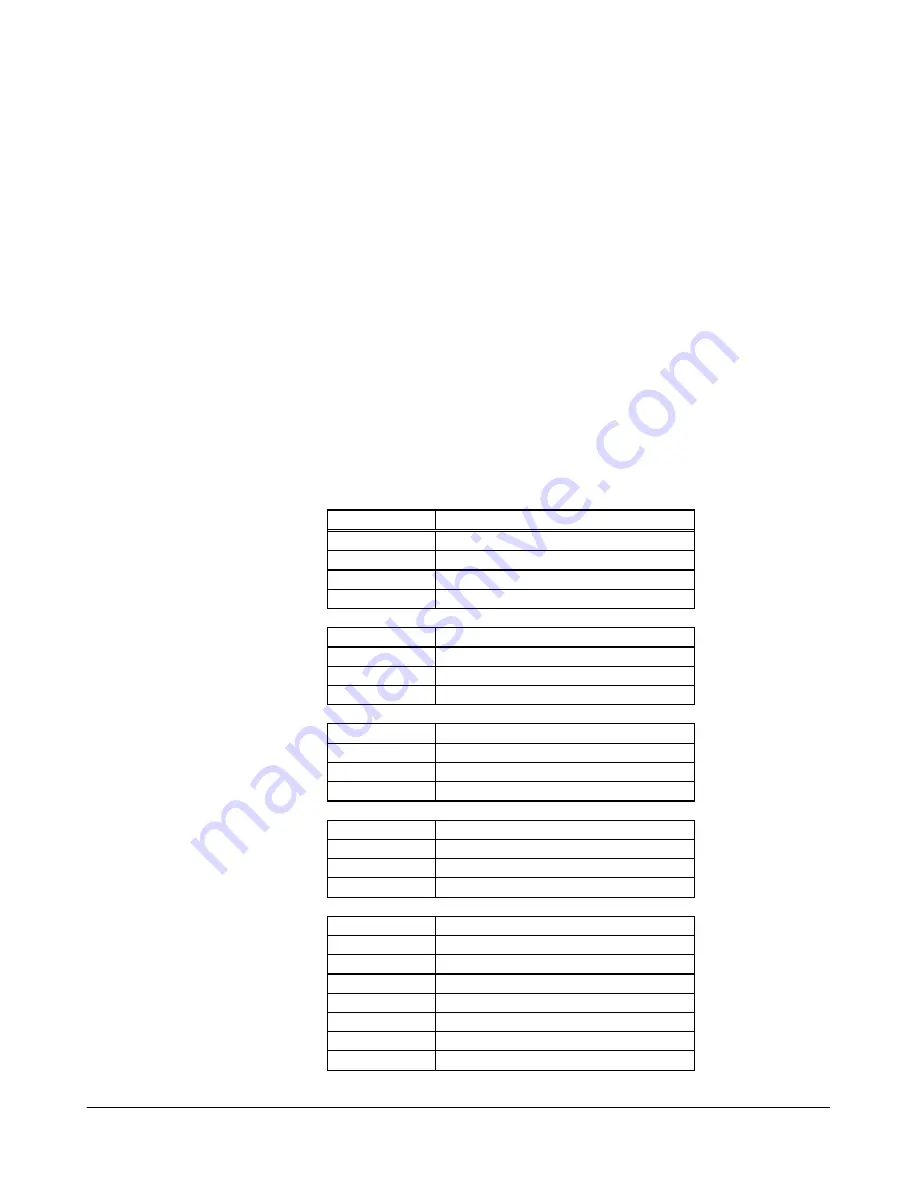

Afterward the screen will display values next to the DRO position axes. The table below assumes machine

has secondary feedback. Machines with motor encoders only will display the reading next to the axis in

question.

Your input

Display

Data displayed.

X +

X

table encoder reading

Y

nothing (should be 0 )

Z

Motor encoder reading

Feedrate

the maximum feedrate attained

Your input

X

table encoder reading

X -

Y

nothing (should be 0 )

Z

Motor encoder reading

Feedrate

the maximum feedrate attained

Your input

X

nothing (should be 0 )

Y +

Y

table encoder reading

Z

Motor encoder reading

Feedrate

the maximum feedrate attained

Your input

X

nothing (should be 0 )

Y -

Y

table encoder reading

Z

Motor encoder reading

Feedrate

the maximum feedrate attained

Your input

X

nothing (should be 0 )

Z +

Y

nothing (should be 0 )

Z

motor encoder reading

Feedrate

the maximum feedrate attained

Your input

X

nothing (should be 0 )

Z -

Y

nothing (should be 0 )

Z

motor encoder reading

Feedrate

the maximum feedrate attained