91

TRAK Machine Tools

Southwestern Industries, Inc.

ProtoTRAK SMX, K2, K3 & K4 & Retrofit Safety, Installation, Maintenance, Service and Parts List Manual

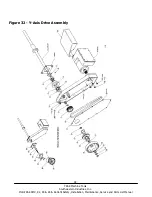

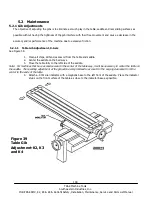

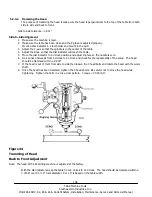

5.1.10 Ball Screw Replacement, Y-Axis (Saddle)

CAUTION!

Never screw a ball screw partially or totally out of its nut. They cannot be

reassembled.

1.

Position the saddle all the way forward.

2.

Remove the hand wheel assembly and bracket.

3.

Remove the sheet metal covers on the front of the machine bed and on the motor mounting bracket.

4.

Remove the motor, then remove the motor mounting bracket.

5.

Remove the rest of the parts on the ball screw journal. Note the orientation of the bearings for reassembly.

6.

Remove the 5/16 x 1 inch screws that attach the ball nut to the yoke.

7.

Remove the ball screw and oil line attached to the elbow fitting on the ball nut.

8.

Remove the elbow and setscrew from the old ball screw flange and fit them similarly in the new ball screw.

9.

Pump oil to be certain it flows through the oil line, and then attach the oil line to the elbow.

10.

Reassemble all assemblies.

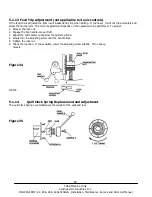

Important

: The clamp nut must be reassembled as follows:

Install rear bearing and seal into bearing housing and slide housing onto the

ball screw.

(Note: Letters on bearings must face each other in the housing.)

Thread the split nut onto the ball screw and tighten the #10-32 clamp screw until

you feel the split nut contact the ball screw threads. It should drag as you tighten

the clamp nut.

Torque the split nut to 50 ft. lb.

Firmly tighten the #10-32 clamp screw to lock the clamp nut in place.

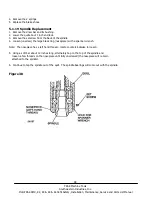

See the diagnostics section under Mechanical Drive Train for an explanation of how to align the ball screw.

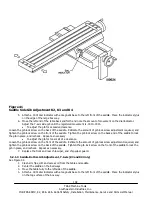

See Figure 32 for an illustration of the Y-axis drive train.