42

TRAK Machine Tools

Southwestern Industries, Inc.

ProtoTRAK SMX, K2, K3 & K4 & Retrofit Safety, Installation, Maintenance, Service and Parts List Manual

Binding in the Drive Train

Check Repeatability using the Repeatability and Positional

Accuracy procedure. Check the torque reading of the Drive

Train. Step by step, carefully inspect the Drive Train for any

binding. It may be necessary to disassemble and then

reassemble the Drive Train. See Mechanical Drive Train (X, Y)

Section 4.2

Servo Drive failure

See Servo Drive Section 4.5

Motor failure

See Motor Section 4.4

3.2.3 Axis Will Not Jog

The system powers up but will not respond to the jog command.

Do the following Service Codes and procedures:

Code 33

Software Identification. This is needed if you call SWI Customer Service.

Code 100

Axis open loop test.

Used to check the maximum feedrate of an axis and if the encoders are

counting.

Possible Cause

Check This

Improper Boot-up

Shut down the system and wait 10 seconds before rebooting

E-Stop is pressed in

Check E-Stop. Especially if both axes will not jog

Servo Drive failure

Especially, if only one axis will not jog;

See Servo Driver Section 4.5

Shorted motor

See Motor Section 4.4

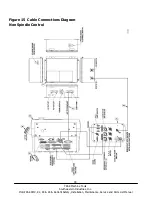

Poor cable or wiring connections

See Electrical Connection Section 2.12

Computer/Pendant failed

See Computer/Pendant diagnostics Section 4.3

3.2.4 Axis Motor Motion Is Not Smooth

While under motor power, the motion is not smooth. The motion appears to be "rough" or jerky”.

Do the following Service Codes and procedures:

Code 33

Software Identification. This is needed if you call SWI Customer Service.

Code 11

Measure's the backlash in the system. Only used on machines with Dual Feedback systems.

Code 12

Feed Forward Constant. High feed forward constants will cause an unstable servo system.

Code 127

Measure's the backlash in the system. Only used on machines with single feedback. Also used

on SMX3 Z axis.

Code 128

Enter backlash compensation. Also used on SMX3 Z axis.

Code 100

Axis open loop test. Used to check the maximum feedrate of an axis and if the encoders are

counting.

Possible Cause

Check This

X and Y Gibs are not adjusted properly

Check the adjustment of the X and Y Gibs using the X

and Y Gib adjustment procedures.

TRAK Sensor or Glass Scale problem

Make sure that the Sensor or Glass Scale is installed

correctly according to the Sensor or Glass Scale

Installation procedures. Check for any loose brackets or

misalignment etc. Also, check to make sure the Sensor or

Glass Scale assemblies are functioning correctly. See

TRAK Sensors or Glass Scales Section 4.6 & 4.7

Calibration or Backlash problem

Recalibrate the machine. Reset the Backlash. Check

Repeatability and Positional Accuracy. See Calibration &

Backlash Constants section.