18-EB41D1-1A-EN

19

Table 9. Natural Gas Only

TABLE OF CUBIC FEET PER HOUR OF GAS FOR

VARIOUS PIPE SIZES AND LENGTHS

PIPE

SIZE

(inch)

LENGTH OF PIPE (Feet)

10

20

30

40

50

60

70

1/2

132

92

73

63

56

50

46

3/4

278

190

152

130

115

105

96

1

520

350

285

245

215

195

180

1–1/4

1050

730

590

520

440

400

370

THIS TABLE IS BASED ON PRESSURE DROP OF 0.3 INCH W.C.

AND 0.6 SP.GR. GAS

G

Ga

ass P

Prre

essssu

urre

e S

Se

ett--u

up

p P

Prre

ecca

au

uttiio

on

nss

IIm

mp

po

orrtta

an

ntt:: Do not connect gas piping to the unit until a

line pressure test has been completed. This

unit should never be exposed to gas line

pressure in excess of 14 inches water

column (1/2 PSIG). The furnace and its

equipment shutoff valve must be

disconnected from the gas supply piping

system during any pressure testing of that

system at test pressures in excess of 1/2

psi.

The furnace must be isolated from the gas supply

piping system by closing its individual manual shut-off

valve during any pressure testing of the gas supply

piping system at test pressures less than or equal to 1/2

psig (3.48 kPa).

G

Ga

ass S

Su

up

pp

plly

y L

Liin

ne

e P

Prre

essssu

urre

e

Before connecting the unit to the gas supply line, be

sure to determine the gas pressure in the line.

If the gas supply pressure is excessive (above 14 inches

water column or 1/2 psig), install a pressure regulator

either at the supply source or in the branch circuit

serving the unit. Once the regulator is installed, set it to

provide a pressure of 7 inches water column with the

unit operating and no greater than 14 inches water

column with the unit not firing.

N

No

otte

e:: Gas pressure in excess of 14 inches water

column (1/2 psig) may damage the regulator,

while improper regulation may result at

pressures lower than 5.5 inches water column at

the unit inlet.

If the supply line pressure is below the minimum

supply pressure indicated on the unit nameplate,

contact the gas supply company.

Follow these steps to complete the installation of the

unit gas piping. See

.

N

No

otte

e:: The shut-off gas cock must be installed outside

of the unit and should meet the specifications of

all applicable national and local codes.

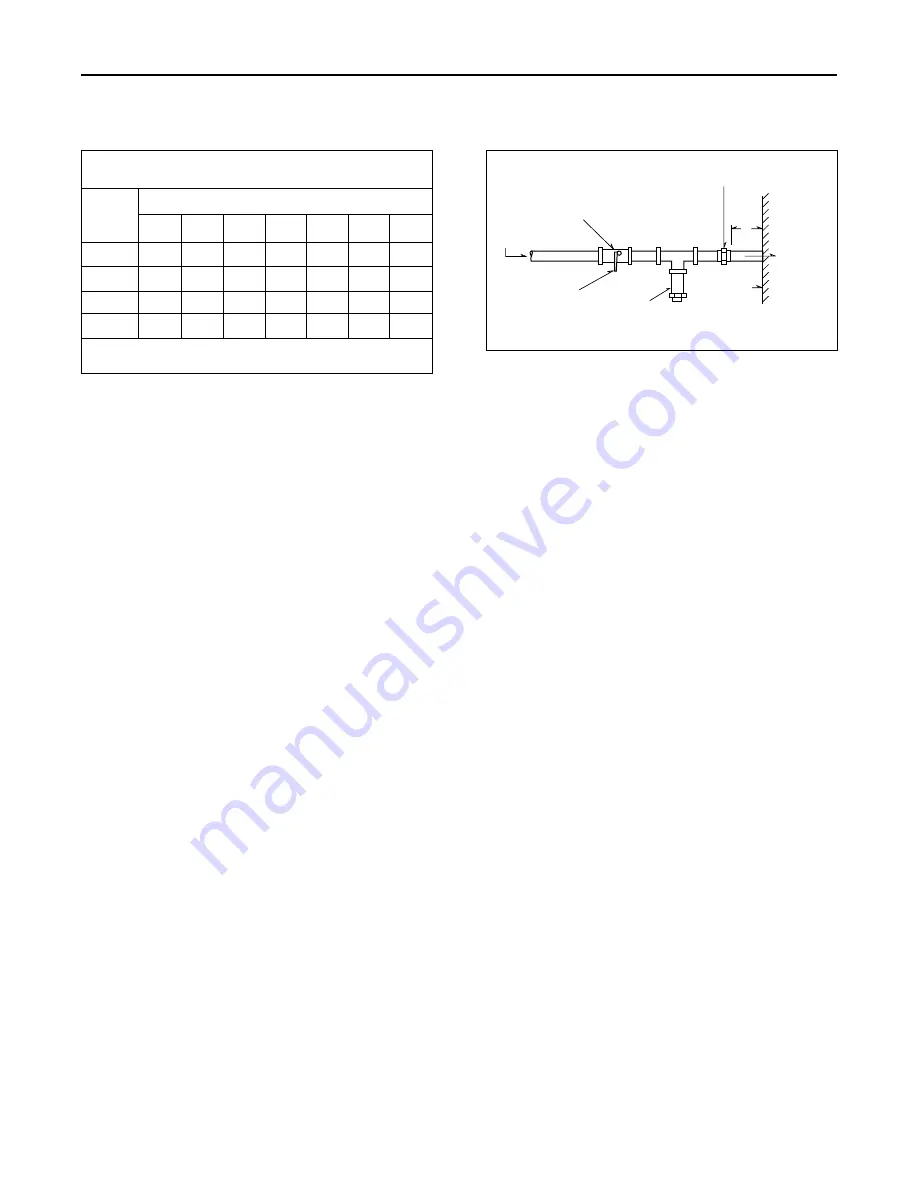

Table 10.

Gas Pipe

DEALER INSTALLED

GROUND UNION

1/8" N.P.T.PLUGGED

ACCESS FOR TEST

GAUGE CONNECTION

FROM

GAS SUPPLY

FIELD SUPPLIED MAIN

GAS VALVE, MUST BE

INSTALLED BY DEALER

OUTSIDE OF UNIT.

UNIT

TO MAIN

CONTROL

VALVE

6"

MIN

DRIP LEG

(6" MIN)

1. Install a tapped, Style A (1/8-inch NPT tap) shut-off

gas cock at the end of the gas supply line near the

unit. Be sure the tapped gas cock is downstream of

the pressure regulator, if used.

2. Install a ground union joint downstream of the

shut-off cock. This joint must also be installed

outside of the unit.

3. Install a drip leg at least six (6) inches in depth next

to the union as shown in

. This drip

leg is required to collect any sediment that may be

deposited in the line.

4. Before connecting the piping circuit to the unit,

bleed the air from the supply line and then cap or

plug the line and test the pressure at the tapped

shut-off cock. The pressure reading should not

exceed 13.8 inches water column.

5. Using an appropriate backup wrench on the gas

valve inlet boss, connect the gas piping to the unit.

Check the completed piping for leaks using a soap

and water solution or the equivalent.

6. After installation of the gas pipe in the unit, the pipe

opening should be closed with the filler/barrier plug

provided.

V

Ve

erriiffy

y M

Ma

an

niiffo

olld

d P

Prre

essssu

urre

e

Check the manifold pressure at the unit gas valve. Do

not exceed the recommended pressure shown on the

unit nameplate.

IIn

np

pu

utt C

Ch

he

ecckk a

an

nd

d A

Ad

djju

ussttm

me

en

ntt

1. Make sure all gas appliances are off except the

furnace.

2. Clock the gas meter with the furnace operating

(determine the dial rating of the meter) for one

revolution.

3. Match the “Sec” column in the Gas Flow (in cfh)

with the time clocked.

4. Read the “Flow” column opposite the number of

seconds clocked.

5.

lists values for a 2 cubic foot dial.

For 1, 1/2, or 5 Cu. Ft. dials use the following

conversions: