General Information

8

COM-SVN003B-EN

Additional basic limitations on operating

conditions:

•

Discharge temperature must not exceed 300°F

(Measure within 6 inches from discharge port).

•

Low superheat is not recommended due to risk of oil

dilution of the compressor. Recommended minimums

are as follows:

–

Electronic expansion valve 10°F.

–

Thermal expansion valve 18-20°F.

•

Minimum oil sump superheat 20°F.

•

Maximum suction gas superheat 54°F.

•

Minimum of 30 psid differential between suction and

discharge must be maintained.

•

Voltage must be within the compression utilization

voltage range.

•

Minimum and maximum saturated evaporating and

condensing temperatures are as shown in the

operating map.

•

Excess liquid refrigerant in the compressor at start up

can cause Oldham coupling failure, involute breakage

and damaged bearings.

•

When the refrigerant system charge exceeds 3 pounds

per ton, crankcase heaters are required.

•

If required, heaters must be energized for a minimum

of eight hours prior to starting the compressor to

insure that liquid refrigerant is not in the compressor at

start up.

•

Under normal operation compressor shall operate for

3 minutes minimum.

•

Max Amps should not exceed listing on compressor

nameplate.

Refrigerant Type

CSHW compressors are approved for use with R-410A

refrigerant only. Any use of hydrocarbon refrigerants or air

is strictly prohibited!

Transportation, Handling, and

Storage

The compressor must be handled in the vertical position

(maximum 15° offset from vertical). Should the

compressor be handled in an upside down position, its

suitability for its use can not be guaranteed.

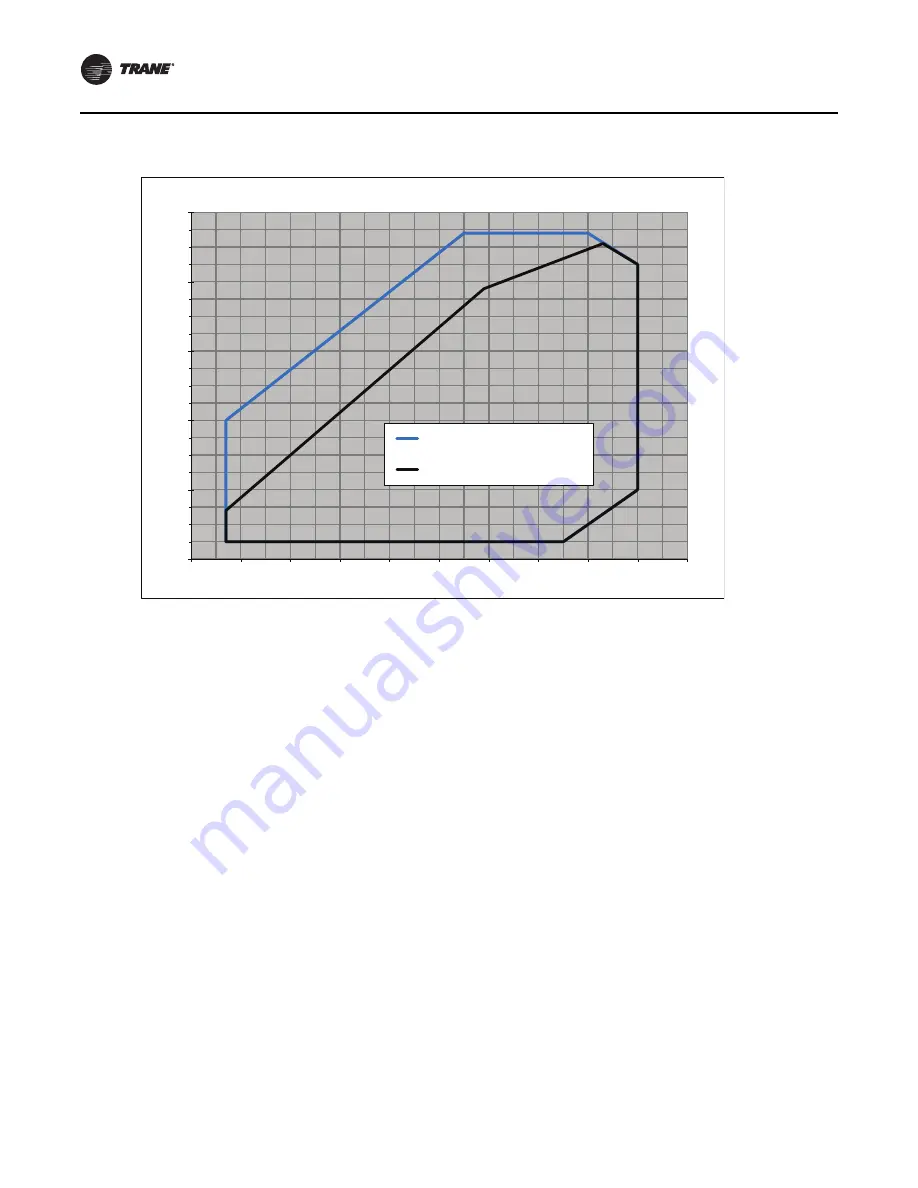

Figure 1.

R-410A operating map for CSHW at 20°F suction superheat

60

80

100

120

140

160

-20

-10

0

10

20

30

40

50

60

70

80

Saturated Discharge

T

e

mperature

(

°

F)

Saturated Suction Temperature (

°

F)

CSHW Operating Envelope --- R-410A

Full Load Operating Map

Unloaded Map; Reduced Operating Map