General Information

COM-SVN003B-EN

9

Damage to compressor or packaging should be reported

to the shipper immediately.

Use a proper method of lifting the compressor, both lifting

ears must be used with a spreader bar.

For approximate compressor weight, see the below table.

The compressor and its packaging must not be exposed to

rain and/or corrosive, flammable atmosphere.

The compressor must not be stored in an environment less

than -31°F (-35°C) or to 160°F (+71°C).

Pre-Installation Inspections

Check the following before using the compressor:

•

Compressor for visible shipping damage.

•

Compressor is the correct model/part number.

•

Compressor is the correct voltage.

Repair Recommendations

NOTICE

Compressor Damage!

Improper handling of the compressor could result on

compressor damage. A compressor that has been

tipped, dropped or transported in a non-upright position

could contain internal damage and it is recommended

that the compressor not be put into service.

WARNING

Heavy Objects!

Failure to follow instructions below or properly lift unit

could result in unit dropping and possibly crushing

operator/technician which could result in death or

serious injury, and equipment or property-only damage.

Ensure that all the lifting equipment used is properly

rated for the weight of the unit being lifted. Each of the

cables (chains or slings), hooks, and shackles used to

lift the unit must be capable of supporting the entire

weight of the unit. Lifting cables (chains or slings) may

not be of the same length. Adjust as necessary for even

unit lift.

Table 2.

Compressor weight without oil charge

Model

Weight (lb)

Weight (kg)

CSHW 047, 050, 052, 056

83.8

38

CSHW 052-2

86

39

CSHW 058, 060, 073

86

39

CSHW 060-2

88.2

40

CSHW 065-2

90.4

41

CSHW 082, 089

99.2

45

CSHW 082-2, 089-2

101.4

46

WARNING

R-410A Refrigerant under Higher Pressure

than R-22

Failure to use proper equipment or components as

described below, could result in equipment failing and

possibly exploding, which could result in death, serious

injury, or equipment damage. The units described in this

manual use R-410A refrigerant which operates at higher

pressures than R-22. Use ONLY R-410A rated service

equipment or components with these units. For specific

handling concerns with R-410A, please contact your local

Trane representative.

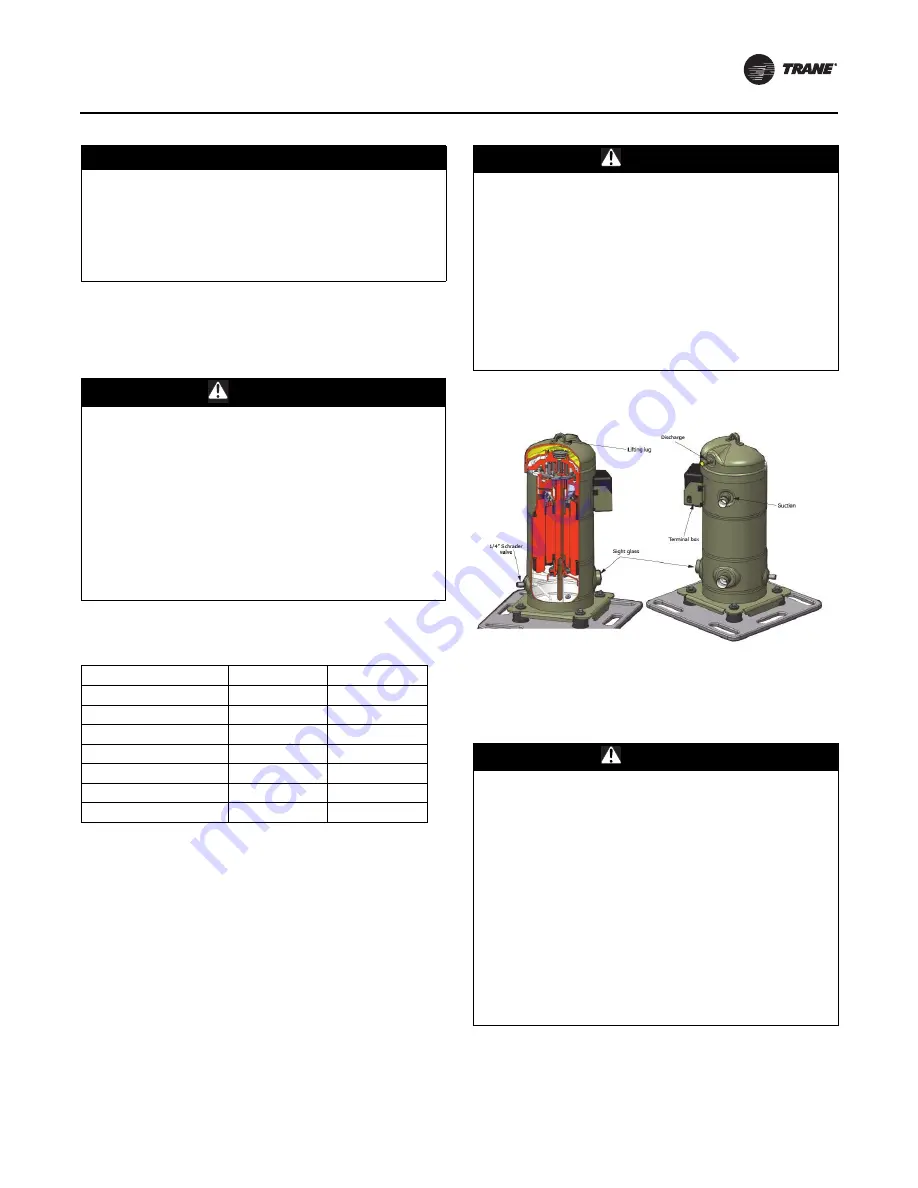

Figure 2.

Model CSHW

WARNING

Hazard of Explosion and Deadly Gases!

Never solder, braze or weld on refrigerant lines or any

unit components that are above atmospheric pressure

or where refrigerant may be present. Always remove

refrigerant by following the guidelines established by

the EPA Federal Clean Air Act or other state or local

codes as appropriate. After refrigerant removal, use dry

nitrogen to bring system back to atmospheric pressure

before opening system for repairs. Mixtures of

refrigerants and air under pressure may become

combustible in the presence of an ignition source

leading to an explosion. Excessive heat from soldering,

brazing or welding with refrigerant vapors present can

form highly toxic gases and extremely corrosive acids.

Failure to follow all proper safe refrigerant handling

practices could result in death or serious injury.