4

TK 56117-6-OP-EN

Danger, Warning, Caution, and Notice . . . . . . . . . . . . . . . . . . . . . . . . 6

Blower Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Automatic Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Hot Surface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

California Proposition 65 Warning Nameplate . . . . . . . . . . . . . . . 8

General Safety Practices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Before Starting the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

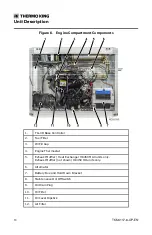

HMI Display Icons and Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . 19

HMI Display Keys and Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . 20

Turning the Unit OFF and OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Changing the Setpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Starting the Diesel Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table of Contents