18-GE08D1-6

3

Installer’s Guide

CAUTION

!

For air handlers not equipped with a factory installed

electric heater, a field installed heater is available from

Trane. Only heaters built by Trane are approved for use

in the air handler. These heaters have been designed

and tested in accordance with UL standards to provide

safe and reliable operation. A list of approved heaters

is provided on the air handler rating nameplate. Heat-

ers that are not factory approved could cause damage

and are not covered under equipment warranty.

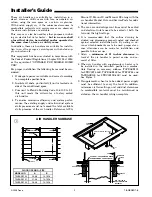

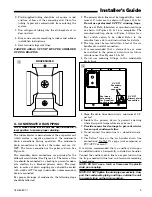

NOTE: If air handler is used WITHOUT a supplementary

electric heater, a sheetmetal plate is required to cover

the open hole in the airflow system. See Figure 2. Also

seal the cabinet air tight where the wire enters.

10. If the unit is installed without a return air duct, ap-

plicable local codes may limit this air handler to in-

stallation only in a single story residence and

within conditioned space.

11. If the outdoor unit is to be installed later, or by oth-

ers, then installation of the air handler must be

made to allow access for refrigerant lines, or attach

refrigerant lines to air handler when installing.

12. Make sure there are provisions for installing con-

densate drain lines.

13. If side, front or rear return is required, air handler

must be elevated or placed on a plenum

(TAYPLNM100 for 2/4TEC3F18 - 48B, 2/4TEC3F60B

or TAYPLNM101 for 2/4TEC3F55B). Connecting re-

turn duct directly to the side, front or rear of the

cabinet is not approved.

14. Route refrigerant and condensate drain lines away

from air handler so they do not interfere with ac-

cess panels and filters.

15. When external accessories are used, the additional

height and width requirements must be considered

in the overall space needed.

16. These units are not approved for outdoor installa-

tion.

17. These units are approved for draw-through appli-

cation only.

NOTE: No atomizing style humidifier is allowed in the

return plenum with the use of this unit.

18.

Flow-through Bypass Humidifiers

Excessive bypass air may cause water blow-off,

which will adversely affect system operation and air

cleaner performance. To verify bypass airflow, fol-

low the Bypass Humidifier Pre-Installation Check-

out and Set-Up Procedures available through your

local distributor. Ask for publication number 18-

CH37D1-1.

Steam and Flow-through Fan Power Duct-

mounted Humidifiers

Follow the humidifier installation instructions.

These should only be installed on the supply air

side of the system.

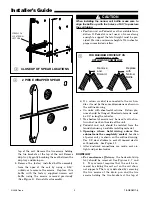

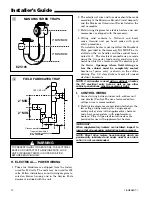

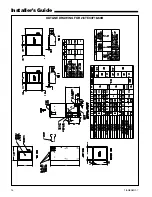

B. TWO PIECE CABINET DISASSEMBLY

(OPTIONAL)

NOTE: For easier installation into tight areas, the 4

and 5 ton air handlers can be disassembled and reas-

sembled after moved to an attic or other space.

Steps for disassembly and reassembly (See Figures 3

and 4)

1.

Disconnect wiring.

2.

Remove center bracket.

3.

Remove blower assembly.

4.

Remove coil.

5.

Cut foil tape - minimum 3" foil tape.

6.

Remove top 8 screws. See Figure 3.

7.

Lift upper section.

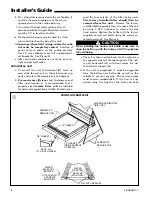

8.

Set air handler in place.

9.

Attach screws - insure gaskets are aligned

along flange.

10.

Use foil tape to seal - use minimum 3" foil tape.

11.

Insert coil.

12.

Reinstall blower assembly.

13.

Reinstall center bracket.

14.

Reconnect wiring.

NOTE: In Downflow, remove coil before blower by

reversing steps 4 and 5.

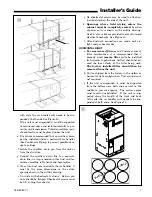

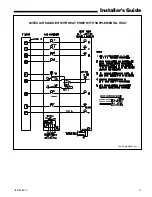

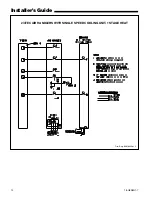

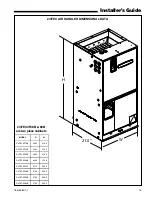

C. UNIT INSTALLATION

UPFLOW

a.

For maximum efficiency

, the horizontal drip

tray should be removed. See Figures 6, 7 and

8. Drip tray removal requires that the coil be

removed by sliding the coil out on the coil

channel supports. The drip tray is detached by

removing the two screws at the drain pan and

the two screws holding the two brackets at the

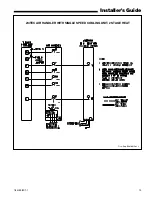

From Dwg. 21B140413

4"

6"

17"

1"

3/8"

1/4" HOLES (4)

ACCESSORY BAY99X123

IF AIRHANDLER IS USED

WITHOUT

A FACTORY FURNISHED

SUPPLEMENTARY HEATER, A PLATE IS REQUIRED TO COVER

THE OPEN HOLE IN THE AIR FLOW SYSTEM

2