Page 21

Installer’s Guide

Service Maintenance

Cooling Season

To keep the unit operating safely and efficiently, the manufacturer

recommends that a qualified service technician check the entire

system at least once each year or sooner if needed. The service

technician should examine these areas of the unit:

〿

filters (for cleaning or replacement)

〿

motors and drive system components

〿

economizer gaskets (for possible replacement)

〿

safety controls (for mechanical cleaning)

〿

electrical components and wiring (for possible replacement

and connection tightness)

〿

condensate drain (for proper sealing and cleaning)

〿

unit duct connections (to see that they are physically sound

and sealed to the unit casing)

〿

unit mounting support (for structural integrity)

〿

the unit (for obvious unit deterioration)

Heating Season

Complete the following unit inspections and service routines

described at the beginning of each heating season.

〿

Visually inspect the unit to ensure that the airflow required

for combustion and condenser coil is not obstructed from the

unit.

〿

Inspect the control panel wiring to verify that all electrical

connections are tight and that the wire insulation is intact

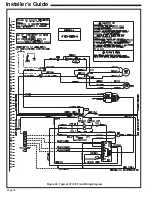

ECM Fan Motor Adjustments

If the airflow needs to be increased or decreased, see the

Airflow Table in the SERVICE FACTS. Information on chang-

ing the speed of the blower motor is in the Blower Performance

Table. Blower speed changes are made on the ECM Fan Control

mounted in the control box. The ECM Fan Control controls the

variable speed motor. There is a bank of 8 dip switches, (See

Figure 21 below), located on the board. The dip switches work

in pairs to match the cooling/heat pump airflow (CFM/TON),

Fan off-delay options and electric heat airflow adjustment. The

switches appear as shown in the Figure below.

CFM

SELECTION

LIGHT

DIP

SWITCHES

CFM FAN

R W3 W2 W1

Y Y LO

J

21C800796P01

CNT03600

Figure 21. ECM Fan Control

Summary of Contents for 4TCY4024

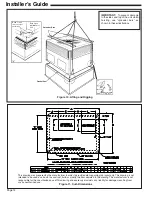

Page 5: ...Page 5 Installer s Guide Figure 2 4TCY4024 through 4TCY4036 2 of 3...

Page 6: ...Page 6 Installer s Guide Figure 3 4TCY4024 through 4TCY4036 3 of 3...

Page 8: ...Page 8 Installer s Guide Figure 5 4TCY4042 through 4TCY4060 2 of 3...

Page 9: ...Page 9 Installer s Guide Figure 6 4TCY4042 through 4TCY4060 3 of 3...

Page 18: ...Page 18 Installer s Guide Figure 20 Typical 4TCY4 Field Wiring Diagram...

Page 22: ...Page 22 Installer s Guide Notes...