Page 3

Installer’s Guide

Read this manual carefully before attempting to install, oper-

ate, or perform maintenance on this unit. Installation and

maintenance should be performed by qualified service techni-

cians only. This unit is listed by Underwriters Laboratory.

Packaged units are designed for outdoor mounting with a

vertical condenser discharge. They can be located either at

ground level or on a roof in accordance with local codes. Each

unit contains an operating charge of refrigerant as shipped.

The indoor fan motor speed adjustment is provided in the

Maintenance section.

Extreme mounting kits are available for slab (BAYEXM-

K003A), curb (BAYEXMK001A), and utility curb (BAYEX-

MK0002B) mountings.

Supplemental heaters are installed separately per the appro-

priate Supplemental Electric Heaters Installer's Guide.

Single power entry kits are installed separately per the ap-

propriate Single Power Entry Kit Installer's Guide.

This guide is organized as follows:

Step 1 - Inspect Shipment

Step 2 - Determine Unit Clearances

Step 3 - Review Location & Recommendation Information

Step 4 - Unit Installation

Step 5 - Unit Startup

Sequence of Operation

Maintenance

Introduction

Contents

Safety Considerations

2

Introduction 3

Step 1-Inspect Shipment

3

Step 2-Determine Unit Clearances

4

Step 3-Review Location & Recommendation

Information

10

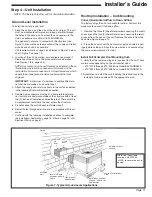

Step 4-Unit Installation

11

Ground Level Installation

11

Rooftop Installation -- Curb Mounting

11

Covert Horizontal Airflow to Down Airflow

11

Install Full Perimeter Roof Mounting Curb

11

Lifting and Rigging

12

Placing the Unit on the Mounting Curb

12

Rooftop Installation -- Frame Mounting

13

Rooftop Installation -- No Frame/Curb

13

Ductwork Installation

16

Attaching Downflow Ductwork to Roof Curb

16

Attaching Downflow Ductwork to Roof Frame

16

Attaching Horizontal Ductwork to Unit

16

Condensate Drain Piping

16

Air Filter Installation

16

Electrical Wiring

17

Electrical Connections

17

Electrical Power

17

Disconnect Switch

17

Overcurrent Protection

17

Power Wiring

17

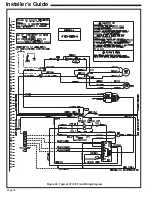

Field Wiring Diagram

18

Control Wiring (Class II)

19

Thermostat Heat Anticipator

19

Step 5-Unit Startup

19

Pre-start Quick Checklist

19

Starting the Unit in the Cooling Mode

19

Operating Pressures

19

Voltage Check

19

Cooling Shutdown

19

Starting the Unit in Heating Mode

20

Heating Shutdown

20

Sequence of Operation

20

General

20

Cooling Mode

20

Heating Mode

20

Final Inspection Checklist

20

Maintenance 20

Owner Maintenance

20

Service Maintenance

21

Cooling Season

21

Heating Season

21

ECM Fan Motor Adjustments

21

Step 1—Inspect Shipment

1. Check for damage after the unit is unloaded. Report promptly

to the carrier any damage found to the unit. Do not drop the

unit.

IMPORTANT:

To prevent damage to the sides and top of the

unit when hoisting, use “spreader bars” as shown on page 14.

2. Check the unit’s nameplate to determine if the unit is correct for

the intended application. The power supply must be adequate

for both the unit and all accessories.

3. Check to be sure the refrigerant charge has been retained

during shipment. Remove the Compressor access panel to

access the 1/4" flare pressure taps.

4. If this unit is being installed on a curb, verify that the correct

curb is provided with the unit.

•

4TCY4024 through 4TCY4036 use BAYCURB050A.

•

4TCY4042 through 4TCY4060 use BAYCURB051A.

5. If the unit is being hoisted, accessory kit BAYLIFT002A is

recommended. It includes a kit of four (4) lifting lugs and

instructions.

NOTE:

If practical, install any internal accessories to the unit

at the shop.

Summary of Contents for 4TCY4024

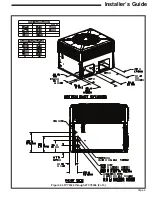

Page 5: ...Page 5 Installer s Guide Figure 2 4TCY4024 through 4TCY4036 2 of 3...

Page 6: ...Page 6 Installer s Guide Figure 3 4TCY4024 through 4TCY4036 3 of 3...

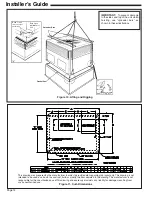

Page 8: ...Page 8 Installer s Guide Figure 5 4TCY4042 through 4TCY4060 2 of 3...

Page 9: ...Page 9 Installer s Guide Figure 6 4TCY4042 through 4TCY4060 3 of 3...

Page 18: ...Page 18 Installer s Guide Figure 20 Typical 4TCY4 Field Wiring Diagram...

Page 22: ...Page 22 Installer s Guide Notes...