18-GE15D1-2

13

Installer’s Guide

ENTER

Push left & right to scroll

through menu options

Push up & down

to scroll through

setup menu

Push ENTER to make selection

Viewing Window

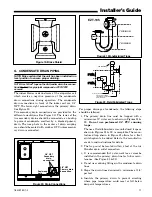

User Interface pictured above adjusts variable speed airflow options.

Figure 23. User Interface

K. UNIT TEST MODE

Unit Test Mode (Air Handler)

The system must be idle or the comfort control

switched to OFF before the Unit Test will run the air

handler. The unit will work the same way in either

Communicating or 24 VAC modes.

To access the Unit Test Mode scroll down through

the User Interface Information Menu until you see

the Unit Test option. Press ENTER. When

prompted select YES and press ENTER. When the

User Interface displays ARE YOU SURE? select YES

and press ENTER to begin the Unit Test.

NOTE: While in Test Mode all comfort control requests will be

ignored but if any button on the User Interface is pressed,

the Unit Test will exit. The Unit Test will exit if a fault is

detected during the test sequence.

The Unit Test will perform the following steps

without delays.

1. Start blower at 50% airflow and Energize EAC

relay.

2. After 10 seconds, go to 100% airflow for 10 seconds.

(User Interface displays UNIT TEST – BLWR)

3. Energize Y1 relay for 15 seconds with 100% airflow.

(User Interface displays UNIT TEST – COOL)

4. De-energize Y1 relay and go to Electric Heat

airflow.

(User Interface displays UNIT TEST – HEAT)

5. Energize blower interlock and stage 1 heat relay.

6. Energize humidifier relay.

7. After 1 second energize stage 2 heat relay.

8. After 1 more second energize stage 3 heat relay.

9. After 5 seconds de-energize blower interlock, stage

1, 2 & 3 heat, humidifier and EAC relays.

(User Interface displays UNIT TEST – EXIT)

Displayed for three seconds

NOTE:

Airflow is default or programmed selections.

J. AIRFLOW ADJUSTMENT

Blower speed changes are made using the User Inter-

face mounted on the communicating Comfort Control

box. The Air Handler control board controls the serial

motor.

NOTE: Serial motors have bearings which are perma-

nently lubricated and under normal use lubrication

is not recommended.

When paired with a communicating outdoor unit, the

Air Handler control board will auto-discover the outdoor

unit size. Default settings are 400 CFM/ton and 1.5

minute at 100% CFM off delay. For other airflow set-

tings, access the User Interface Menu (See Figure 23)

to select options or use the options in the communicat-

ing Comfort Control. The full menu is listed in Figure

24.

When Air Handler is to be used in 24 VAC mode,

access the User Interface to change the comfort

control mode to 24 VAC, match the airflow for the

outdoor unit size (tons), adjust the cooling air-

flow (CFM/ton), set the Fan on/off-delay options,

and adjust the heating airflow per the Nameplate

specifications on the air handler front panel.

The

User Interface appears as shown in Figure 23. The full

menu is listed in Figure 25.

If the airflow needs to be increased or decreased, see

the Blower Performance Table in the Service Facts. In-

formation on changing the speed of the blower motor

for your specific outdoor model size is in the Blower

Performance Table.

Be sure to set the airflow for the correct tonnage.

Refer to the User Interface for correct setting.

If the optional humidistat is used, remove R-BK jumper

from the low voltage terminal board (not shown) and in-

stall the humidistat between R and BK. (Jumper R to O

for cooling-only/non-heat pump systems with a humidis-

tat.)