18-GE15D1-2

5

Installer’s Guide

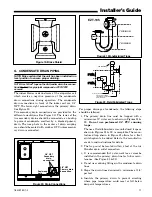

Figure 7. FIELD CHARGER Removal

Figure 8. Protector Plate Removal

4.

The horizontal drip tray should be removed

for

maximum efficiency

. See Figures 9, 10, and 11.

a.

Remove the coil by sliding it out on the coil

channel supports. For the 4TEE3D05, 07, 09, & 10

units, there is a coil support tab at the top of the

coil, connected to the case, that must be removed

first.

b.

Remove 1" insulation strip covering the lip of

the drip tray. See Figure 9.

c.

Detach the tray by removing the two screws at

the drain pan and the two screws holding the two

brackets at the top of the coil. See Figures 10 & 11.

d.

Remove drip tray by gently breaking the seal

between the drip tray and drain pan.

5.

Replace the factory installed baffle with supplied

narrow baffle. See Figure 12.

a.

Remove the factory installed baffle assembly

from the apex of the coil by using a 5/16" nutdriver

to remove the screws.

b.

Replace this baffle with the factory supplied nar-

row coil baffle using the screws removed previously.

See Figure 12.

6.

Position unit on Pedestal or other suitable founda-

tion. If Pedestal is not used, a frame strong enough

to support the total weight must be provided. Pro-

vide a minimum height of 14 inches for proper un-

restricted airflow. In open return applications, in-

stallation requires a BAYPLNM or TASB stand.

7.

If a return air duct is connected to the air handler,

it must be the same dimensions as shown in Figure

17 and the outline drawing on page 21.

8.

On units with sheetmetal returns the Return

plenum must be flanged, sheetmetal screws

must be 1/2" in length or shorter. Self-tapping

screws are supplied with the unit accessory

pack.

Figure 9. Remove Insulation Strip

Figure 10. Remove Screws at Drain Pan