Table of Contents

General ............................................................................... 1

Application Information ................................................ 1

Recommendation ............................................................. 2

Furnace in Upflow Position .......................................... 2

Furnace in Downflow Position ..................................... 2

Furnace in Horizontal Right Position ........................ 3

Furnace in Horizontal Left Position ........................... 4

Maximum Airflow Setting, CFM ................................... 5

Installing / Brazing Refrigerant Lines ....................... 5

Leak Check........................................................................ 6

Condensate Drain Piping .............................................. 6

Cleaning the Coil ............................................................. 6

Outline Drawings ............................................................ 7

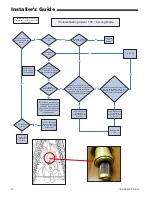

Troubleshooting Indoor TXV / Cooling Mode ......... 10

Installer’s Guide

ALL phases of this installation must comply with NATIONAL, STATE AND LOCAL CODES

IMPORTANT —

This Document is

customer property

and is to remain with this unit. Please return to service informa-

tion pack upon completion of work.

WARNING

!

WARNING (Medium/high pressure)

Contains Refrigerant!

System contains oil and refrigerant under high pressure.

Recover refrigerant to relieve pressure before opening the

system. See unit nameplate for refrigerant type. Do not

use non-approved refrigerants, refrigerant substitutes, or

refrigerant additives.

Failure to follow proper procedures or the use of non-

approved refrigerants, substitutes, or refrigerant additives

could result in death, serious injury, or equipment damage.

A341869P33

IMPORTANT: Review your installation requirements. Check

the table on the outline drawings and note all dimensions

for your coil before beginning the installation.

Figure 1

18-AD35D1-2D-EN

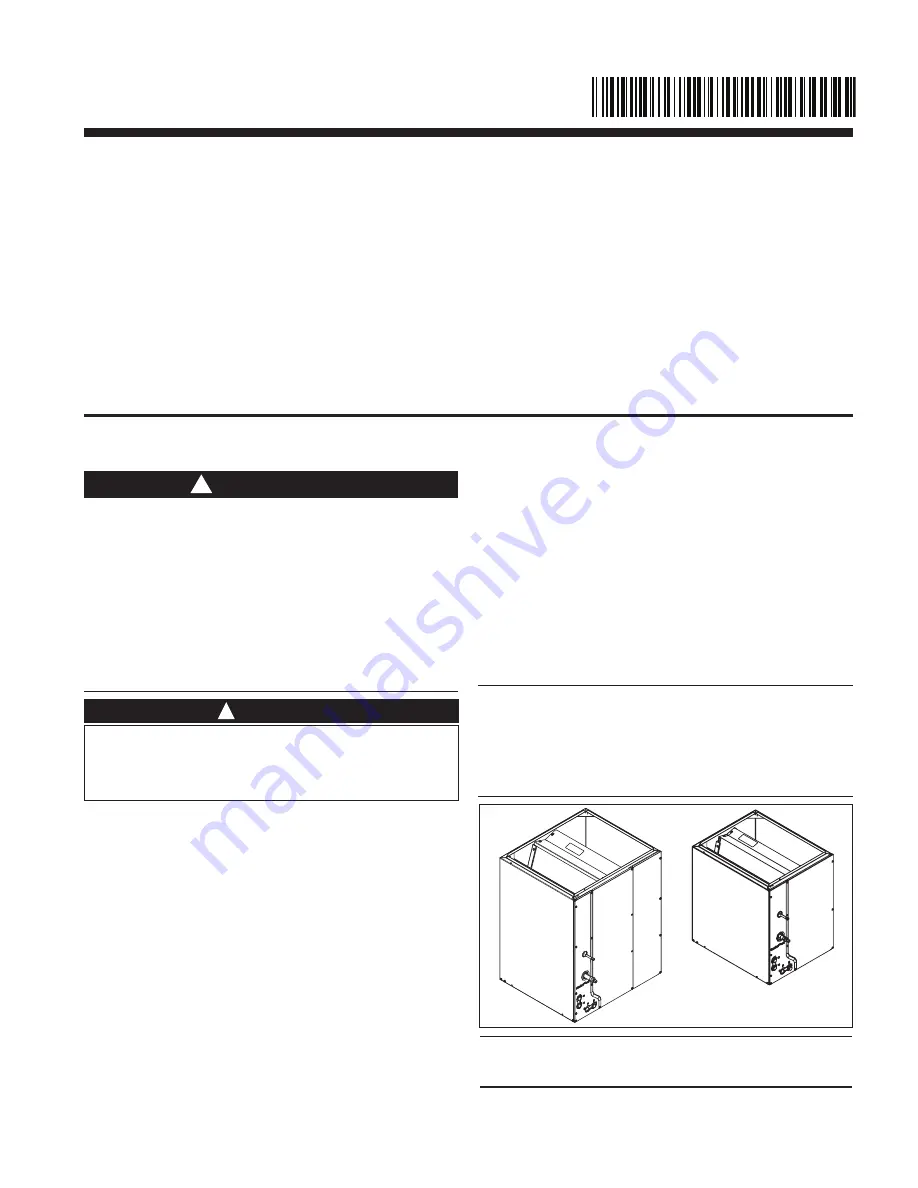

Cased Aluminum "Convertible" Coils

Models:

4TXCA002DS3HCA

4TXCA032DS3HCA

4TXCB003DS3HCA

4TXCB004DS3HCA

4TXCB006DS3HCA

4TXCC005DS3HCA

4TXCC007DS3HCA

4TXCD008DS3HCA

4TXCC009DS3HCA

4TXCD010DS3HCA

NOTE:

OPTIONAL DOWNFLOW GASKET INSTALLATION: For

unusually humid applications that expect prolonged

operation above 70% RH, it is recommended to use the

BAYGSKT001A0 gasket kit to prevent water from forming

on the bottom of the drain pan and dripping into the sup-

ply ductwork.

WARNING

!

This product can expose you to chemicals including lead, which

are known to the State of California to case cancer and birth defects

or other reproductive harm. For more information go to www.

P65Warnings.ca.gov

A. GENERAL

These coils are designed for use in combination with a heat pump

or cooling outdoor section using

R-410A REFRIGERANT

.

The 4TXC equipment has been evaluated in accordance with

the Code of Federal Regulations, Chapter XX, Part 3280 or the

equivalent. “Suitable for Mobile Home use” The height of the

Furnace, Coil and discharge duct work must be 7 ft. or less.

Inspect the coil for shipping damage. Notify the transporta-

tion company immediately if the coil is damaged.

B. APPLICATION INFORMATION

1. FURNACE AND COIL

The coil MUST BE installed downstream (in the outlet air)

of the furnace.

2. INDOOR UNIT AIRFLOW

Indoor unit must provide the required airflow for the heat

pump or cooling combinations approved for these coils.