6

18-AD35D1-2D-EN

Installer’s Guide

When replacing the bulb and hose clamp, the clamp

should be "snug" but not "tight" - spec is to torque the

hose clamp to 20+/-5in-lb.

9. Wrap the TXV with insulation after the hose clamp has

been installed.

J. LEAK CHECK

1. Using a manifold gauge, connect an external supply of dry

nitrogen to the gauge port on the liquid line.

2. Pressurize the connecting lines and indoor coil to 150 PSIG

maximum.

3. Leak check brazed line connections using soap bubbles.

Repair leaks (if any) after relieving pressure.

4. Evacuate and charge the system per the instructions pack-

aged with the outdoor unit.

K. CONDENSATE DRAIN PIPING

Condensate drain connections are located in the drain pan

at the bottom of the coil/enclosure assembly. The female

threaded fitting protrudes outside of the enclosure for external

connection. A field fabricated trap is not required for proper

drainage due to the positive pressure of the furnace; however,

it is recommended to prevent efficiency loss of conditioned air.

1. The drain hole in the drain pan must be cleared of all

insulation.

2. Insulate the primary drain line to prevent sweating where

dew point temperatures may be met. (Optional depending on

climate and application needs)

3. Connect the secondary drain line to a separate drain line

(no trap is needed in this line).

Figure 13

Figure 14

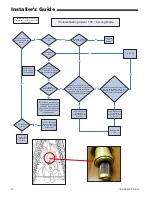

L. CLEANING THE COIL

The two piece door (3-piece on 24.5" wide models) allows

removal of the outer casing doors without interference from

refrigerant or condensate lines. Once the outer doors are

removed the split inner coil panels can be easily removed.

The inside and outside of the coil can be easily cleaned with

a brush and vacuum with the panels removed. See Figure 13.

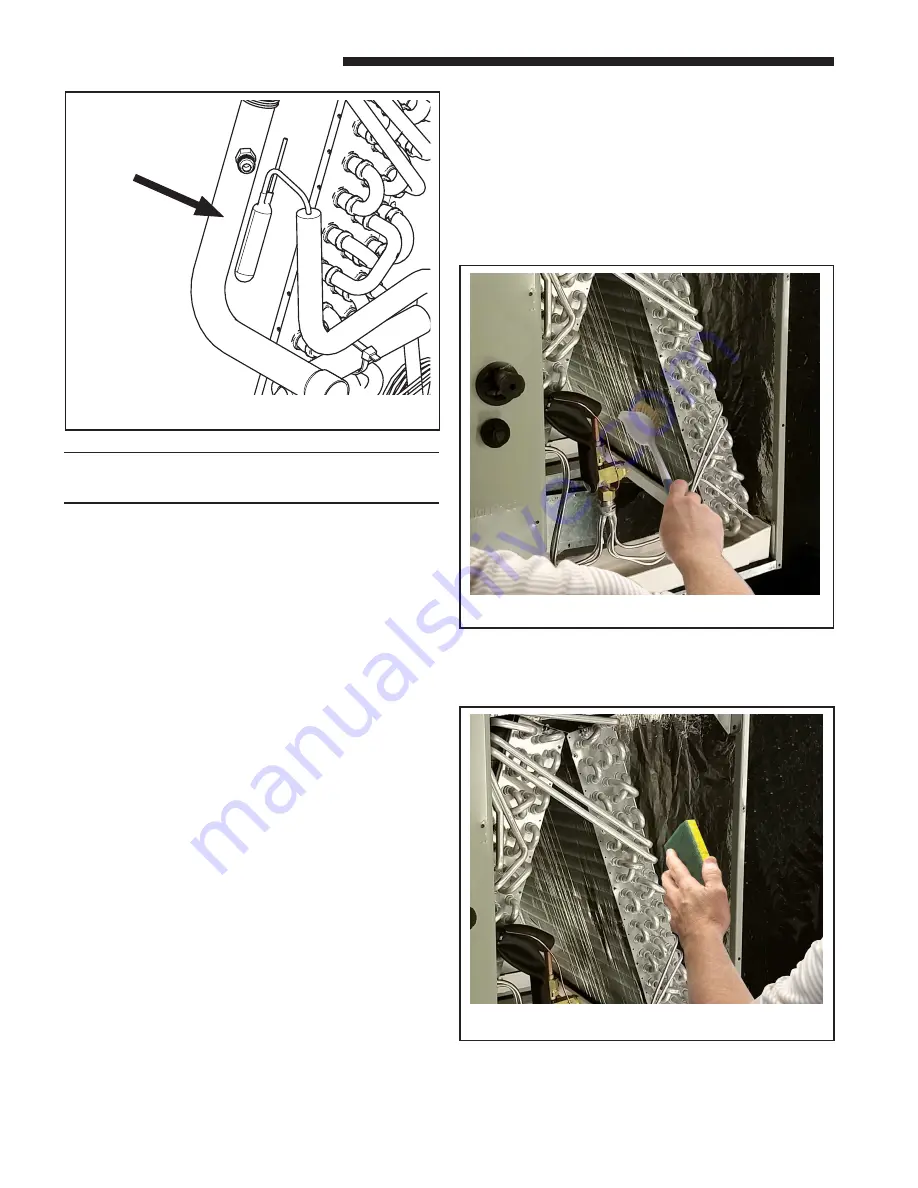

The foil covered insulation should be wiped down and residual

dirt and dust should be vacuumed up to maintain good air

quality. See Figure 14.

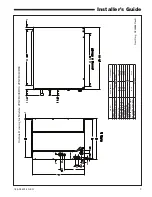

Figure 12

Capillary tubes will

come out the top of

bulb when positioned

correctly.