8

Service Facts

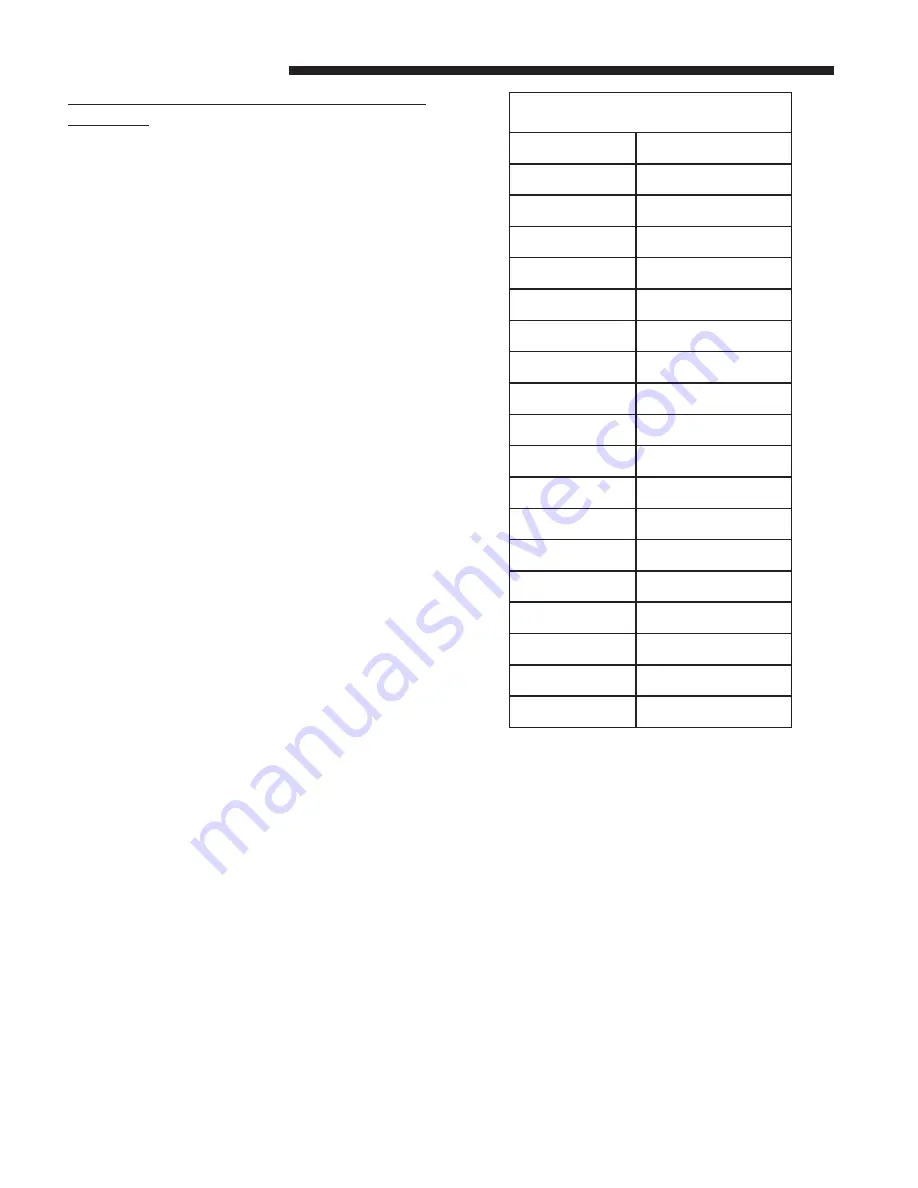

CHARGING IN COOLING ABOVE 55°F OD

AMBIENT

The preferred method is to weigh in the factory charge

per the unit nameplate. If weighing in the charge is not

practical, the following method can be used. The fol-

lowing charging method is prescribed for systems with

indoor TXVs.

1. For best results – the indoor temperature should be kept

between 70°F to 80°F. Add system heat if needed.

2. Whenever charge is removed or added, the system must

be operated for a minimum 20 minutes to stabilize before

accurate measurements can be made.

3. Measure Liquid Line Temperature and Refrigerant Pres-

sure at service valves in the compressor compartment.

4. Locate your liquid line temperature in the left column of

the table, and the intersecting liquid line pressure under

the subcool value column. Add refrigerant to raise the

pressure to match the table, or remove refrigerant to

lower the pressure. Again, wait 20 minutes for the sys-

tem conditions to stabilize before adjusting charge again.

5. When system is correctly charged, you can refer to

System Pressure Curves (on page 2) to verify typical

performance.

R-410A Subcooling Charging Table

10 (ºF) Subcooling

Liquid

Liquid

Temperature

Pressure

(ºF)

PSIG

55

185

60

200

65

217

70

235

75

254

80

274

85

295

90

317

95

340

100

364

105

390

110

417

115

445

120

475

125

506

Summary of Contents for 4YCY4036B-SF-1H

Page 9: ...9 Service Facts...

Page 12: ...Trane 6200 Troup Highway Tyler TX 75707 01 13...