Installer’s Guide

18-CD21D1-12

9. Using a leak detection solution or soap suds, check

for leaks at the pressure outlet boss and pressure

tap test screw.

10. Turn on system power and check operation of the

unit.

▲

CAUTION

!

Replace and/ or tighten all plugs removed or loosened

when adjusting gas pressure. Leak check the fittings

before placing the furnace into regular service.

Failure to follow this warning could result in fire, explo-

sion, or property damage.

Table 10 lists the main burner orifices shipped with

the furnace. If a change of orifices is required to cor-

rect the input rate, refer to Table 11.

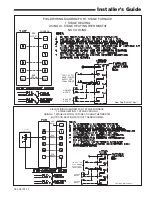

TABLE 9

NATURAL GAS ONLY

TABLE OF CUBIC FEET PER HOUR OF GASFOR VARIOUS PIPE

SIZES AND LENGTHS

PIPE-

SIZE

LENGTH OF PIPE

10

20

30

40

50

60

70

1/2

132

92

73

63

56

50

46

3/4

278

190

152

130

115

105

96

1

520

350

285

245

215

195

180

1-1/4

1050

730

590

520

440

400

370

This table is based on pressure drop of 0.3 inch W.C. and 0.6 SP.GR. gas

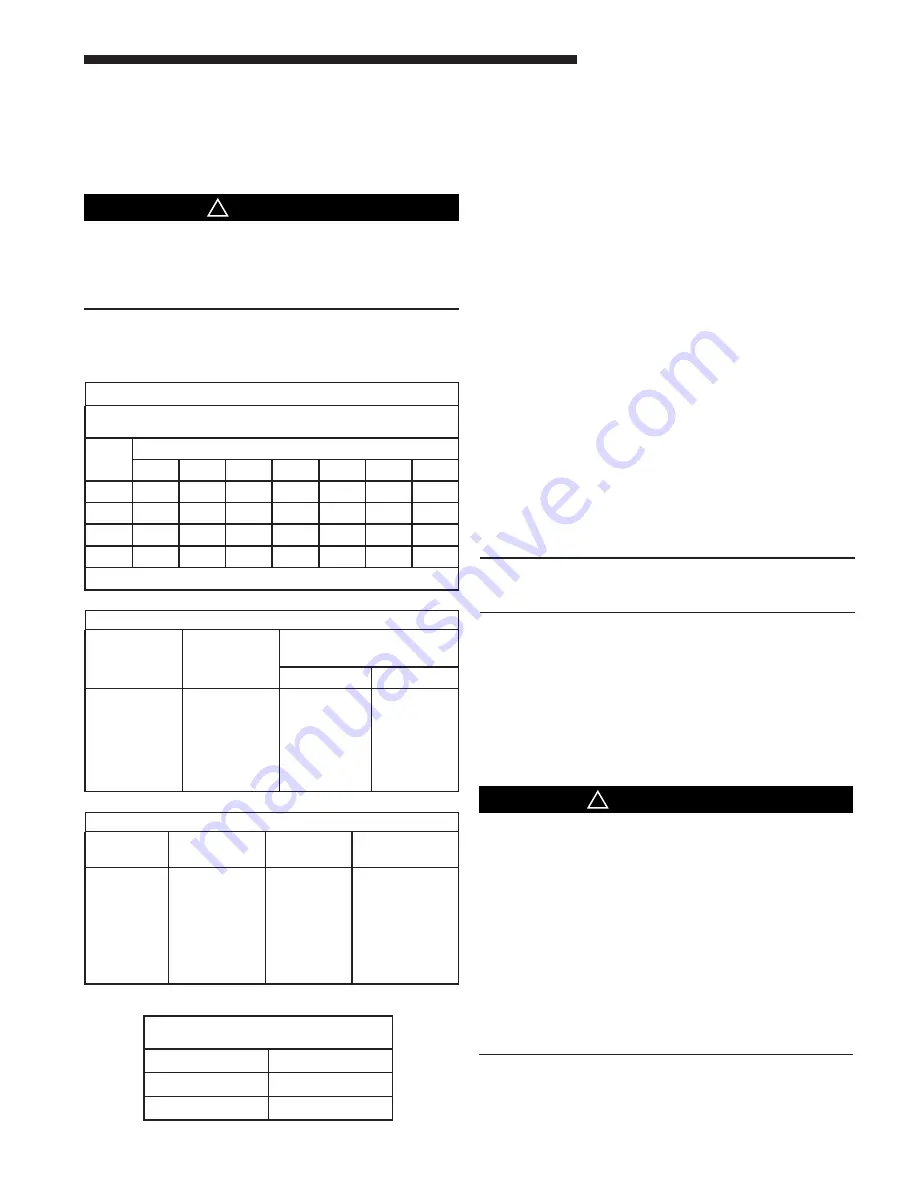

TABLE 10

ORIFICE SIZES

INPUT

RATING

BTUH

NUMBER

OF

BURNERS

MAIN BURNER ORIFICE

DRILL SIZE

NAT. GAS

LP GAS

40,000

60,000

80,000

100,000

120,000

140,000

2

3

4

5

6

7

45

45

45

45

45

45

56

56

56

56

56

56

TABLE 11

PART NUMBERS FOR REPLACEMENT ORIFICES

DRILL

SIZE

PART

NUMBER

DRILL

SIZE

PART

NUMBER

44

45

46

47

48

49

50

ORF00501

ORF00644

ORF00909

ORF00910

ORF01099

ORF00503

ORF00493

54

55

56

57

58

59

ORF00555

ORF00693

ORF00907

ORF00908

ORF01338

ORF01339

HIGH ALTITUDE DERATE

Input ratings (BTUH) of these furnaces are based on

sea level operation and should not be changed at eleva-

tions up to 2,000 ft.

If the installation is 2,000 ft. or above, the furnace in-

put rate (BTUH) shall be reduced 4% for each 1,000

ft. above sea level. The furnace input rate shall be

checked by clocking the gas flow rate (CFH) and mul-

tiplying by the heating value obtained from the local

utility supplier for the gas being delivered at the in-

stalled altitude. Input rate changes can be made by

adjusting the manifold pressure (min 3.0 - max 3.7 in.

W.C. - Natural Gas) or changing orifices (orifice change

may not always be required). If the desired input rate

cannot be achieved with a change in manifold pressure,

then the orifices must be changed. LP installations will

require an orifice change.

Installation of this furnace at altitudes above 2,000 ft.

(610m) shall be in accordance with local codes, the

Na-

tional Fuel Gas Code, ANSI Z223.1/ NFPA 54 or Na-

tional Standard of Canada, Natural Gas and Propane

Installation Code, CSA B149.1.

Installation of this fur-

nace at altitudes above 2,000 ft. (610m) shall be made

in accordance with the listed high Altitude Conversion

Kit available with this furnace.

IMPORTANT:

Re-install the propane orifices to the same depth as the

orifices supplied with the equipment.

See Table 14 for help in selecting orifices if orifice

change is required. Furnace input rate and tempera-

ture rise should be checked again after changing ori-

fices to confirm the proper rate for the altitude.

Installations above 4,000 feet may require a pressure

switch change. If required, use the BAYHALT*** Kit

(High Altitude Accessory Kit) listed in PRODUCT

DATA.

▲

WARNING

!

EXPLOSION HAZARD!

PROPANE GAS IS HEAVIER THAN AIR AND MAY

COLLECT IN ANY LOW AREAS OR CONFINED SPAC-

ES. IN ADDITION, ODORANT FADE MAY MAKE THE

GAS UNDETECTABLE EXCEPT WITH A WARNING

DEVICE. IF THE GAS FURNACE IS INSTALLED IN A

BASEMENT, AN EXCAVATED AREA OR A CONFINED

SPACE, IT IS STRONGLY RECOMMENDED TO CON-

TACT A GAS SUPPLIER TO INSTALL A GAS DETECT-

ING WARNING DEVICE IN CASE OF A GAS LEAK

.

NOTE:

The manufacturer of your furnace does NOT test

any detectors and makes no representations regarding

any brand or type of detector.

FINAL MANIFOLD PRESSURE SET-

TINGS (inches w.c.)

FUEL

PRESSURE

NATURAL GAS

3.5" W.C.

LP GAS

10.5" W.C.

TABLE 12