14

18-CD31D1-3

Installer’s Guide

TABLE 7

MASONRY CHIMNEY VENTING

Tile Lined Chimney

Chimney Lining

Type Furnace

Internal

External

“B” Vent

Flexible

Metal Liner

Single Fan

Assist

No

No

Yes

Yes*

Fan Assist

+

Fan Assist

No

No

Yes

Yes*

Fan Assist

+

Natural

Yes

No

Yes

Yes*

* Flexible chimney liner size is determined by using the type “B” vent size

for the available BTUH input, then reducing the maximum capacity by 20%

(multiply maximum capacity times 0.80). The minimum capacity is the same

as shown in the “B” vent tables.

EXTERNAL MASONRY CHIMNEY

Venting of fan assisted appliances into external chimneys

(one or more walls exposed to outdoor temperatures), re-

quires the chimney be lined with type “B”, double wall vent

or suitable flexible chimney liner material. This applies in

all combinations of common venting as well as for fan as-

sisted appliances vented alone.

The following installation practices are recommended to

minimize corrosion caused by condensation of flue products

in the furnace and flue gas system.

S

WARNING

!

CARBON MONOXIDE POISONING HAZARD

Failure to follow the installation instructions for the vent-

ing system being placed into operation could result in

carbon monoxide poisoning or death.

1. Avoid an excessive number of bends.

2. Horizontal runs should pitch upward at least 1/4" per

foot.

3. Horizontal runs should be as short as possible.

4. All vent pipe or connectors should be securely support-

ed and must be inserted into, but not beyond the inside

wall at the chimney vent.

5. When vent connections must pass through walls or

partitions of combustible material, a thimble must be

used and installed according to local codes.

6. Vent pipe through the roof should be extended to a

height determined by National Fuel Gas Code or local

codes. It should be capped properly to prevent rain

water from entering the vent. Roof exit should be wa-

terproofed.

7. Use type “B” double wall vent when vent pipe is routed

through cool spaces (below 60° F.).

8. Where long periods of airflow are desired for comfort,

use long fan cycles instead of continuous airflow.

9. Apply other good venting practices as stated in

the venting section of the National Fuel Gas Code

ANSI Z223.1 “latest edition”.

10.

Vent connectors serving appliance vented by

natural draft or non-positive pressure shall not

be connected into any portion of a mechanized

draft system operating under positive pressure.

11. Horizontal pipe runs must be supported by hangers,

straps or other suitable material in intervals at a mini-

mum of every 3 feet of pipe.

12. A furnace shall not be connected to a chimney or flue

serving a separate appliance designed to burn solid

fuel.

13. The flow area of the largest section of vertical vent or

chimney shall not exceed 7 times the smallest listed ap-

pliance categorized vent area, flue collar area, or draft

hood outlet area unless designed in accordance with

approved engineering methods.

Maximum Vent or Tile

Lined Chimney Flow Area

*Drafthood outlet diameter, flue collar diameter, or listed appliance categorized vent

diameter.

(D*)

2

4

=

X 7

F

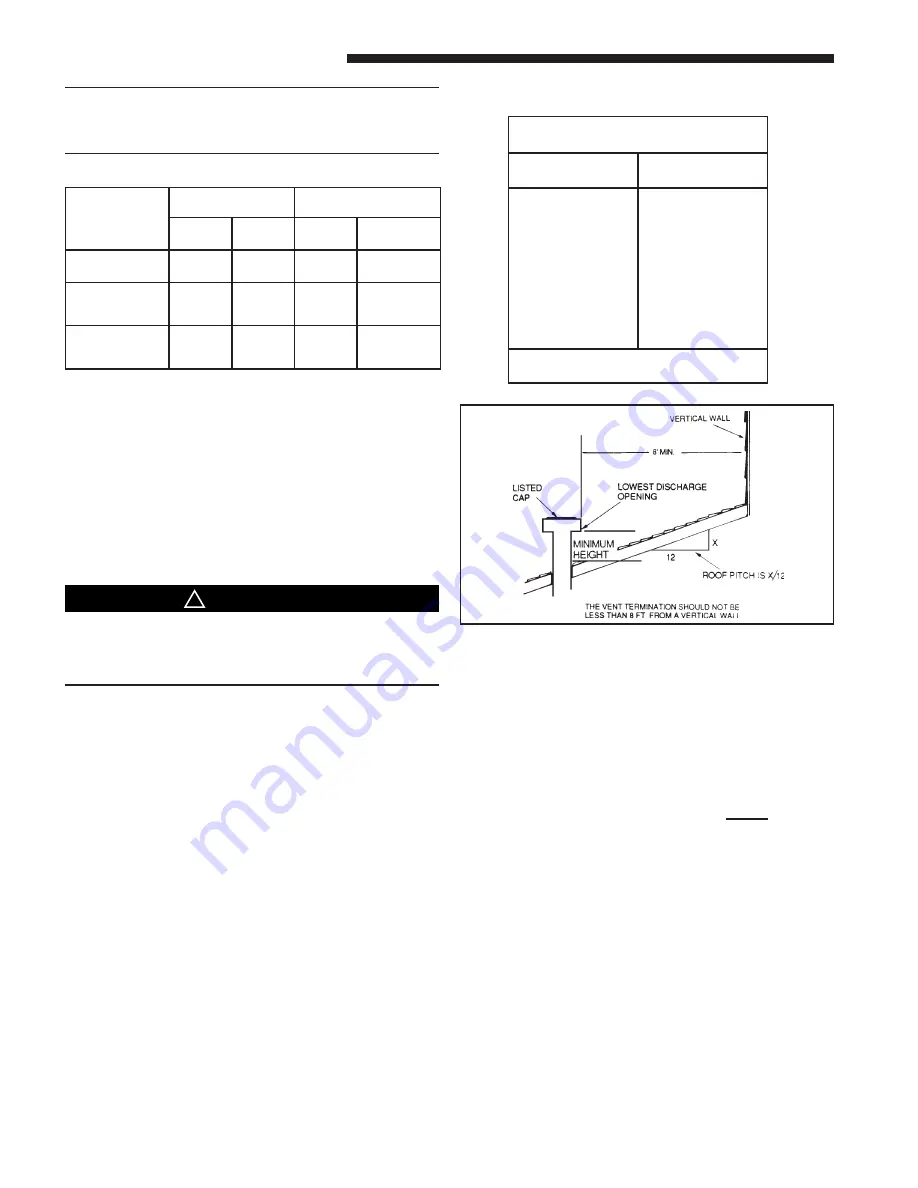

TABLE 8

GAS VENT TERMINATION

ROOF PITCH

MINIMUM HEIGHT

FLAT TO 7/12

OVER 7/12 TO 8/12

OVER 8/12 TO 9/12

OVER 9/12 TO 10/12

OVER 10/12 TO 11/12

OVER 11/12 TO 12/12

OVER 12/12 TO 14/12

OVER 14/12 TO 16/12

OVER 16/12 TO 18/12

OVER 18/12 TO 20/12

OVER 20/12 TO 22/12

1.0 FEET *

1.5 FEET

2.0 FEET

2.5 FEET

3.25 FEET

4.0 FEET

5.0 FEET

6.0 FEET

7.0 FEET

7.5 FEET

8.0 FEET

* THIS REQUIREMENT COVERS MOST INSTALLATIONS

NOTE:

The following section does not apply if BAYVENT800B

(Masonry Chimney Vent Kit) is used. All instructions with

the kit must be followed.