18-CD31D1-3

3

Installer’s Guide

Installation Instructions

3

General Installation Instructions

3

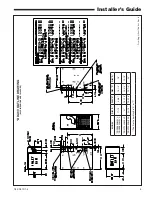

Location and Clearances

3

Outline Drawing

4-5

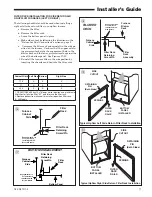

Upflow Installation

6

Downflow Installation

6

Horizontal Installation

6

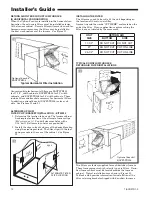

Air for Combustion and Ventilation

7

Duct Connections

8

Return Air Filters

9-13

General Venting Instructions

13

Venting into a Masonry Chimney

13

Electrical Connections

15

Field Wiring Diagrams

16-17

Gas Piping

18

Combustion and Input Check

18

High Altitude Derate

20

Start Up and Adjustment

21

Preliminary Inspections

21

Lighting Instructions

21

Sequence Of Operation

21

Control and Safety Switch Adjustment

22

Abnormal Conditions

23

IFC Error Flash Codes

24

Contents

GENERAL INSTALLATION INSTRUCTIONS

The manufacturer assumes no responsibility for equipment

installed in violation of any code or regulation.

It is recommended that Manual J of the Air Conditioning

Contractors Association (ACCA) or A.R.I. 230 be followed

in estimating heating requirements. When estimating

heating requirements for installation at Altitudes above

2000 ft., remember the gas input must be reduced (See GAS

INPUT ADJUSTMENT).

Material in this shipment has been inspected at the

factory and released to the transportation agency

without known damage. Inspect exterior of carton

for evidence of rough handling in shipment. Unpack

carefully after moving equipment to approximate

location. If damage to contents is found, report the

damage immediately to the delivering agency.

Codes and local utility requirements governing the instal-

lation of gas fired equipment, wiring, plumbing, and flue

connections must be adhered to. In the absence of local

codes, the installation must conform with latest edition of

THE.ATIONAL&UEL'AS#ODE!.3):s.ATIONAL)NSTAL

-

lation Code, CAN/CGA B149.1. The latest code may be

obtained from the American Gas Association Laboratories,

400 N. Capitol St. NW, Washington D.C. 20001.

1-800-699-9277 or www.aga.org

These furnaces have been classified as Fan Assisted Com-

bustion system CATEGORY I furnaces as required by

ANSI Z21.47 “latest edition” and CAN/CGA 2.3. Therefore

they do not require any special provisions for venting other

than what is indicated in these instructions. (Category I

defined on page 13).

S

CAUTION

!

To prevent shortening its service life, the furnace should

not be used as a “Construction Heater” during the finish-

ing phases of construction until the requirements listed

in item 9, a-g of the safety section of this publication have

been met. Condensate in the presence of chlorides and

fluorides from paint, varnish, stains, adhesives, cleaning

compounds, and cement create a corrosive condition

which may cause rapid deterioration of the heat exchang-

er.

S

CAUTION

!

Do not install the furnace in a corrosive or contaminated

atmosphere.

S

WARNING

!

These furnaces are not approved or intended for installa-

tion in manufactured (mobile) housing, trailers, or rec-

reational vehicles. Failure to follow this warning could

result in property damage, personal injury, or death.

S

WARNING

!

Do not install the furnace directly on carpeting, tile or

other combustible material other than wood flooring. For

vertical downflow application, subbase (BAYBASE205)

must be used between the furnace and combustible floor-

ing. When the downflow furnace is installed vertically

with a cased coil, a subbase is not required.

LOCATION AND CLEARANCES

The location of the furnace is normally selected by the

architect, the builder, or the installer. However, before the

furnace is moved into place, be sure to consider the follow-

ing requirements:

1. Is the location selected as near the chimney or vent and

as centralized for heat distribution as practical?

2. Do all clearances between the furnace and enclosure

equal or exceed the minimums stated in Clearance

Table on the Outline Drawings.

3. Is there sufficient space for servicing the furnace and

other equipment? A minimum of 24 inches front acces-

sibility to the furnace must be provided. Any access

door or panel must permit removal of the largest com-

ponent.

4. Are there at least 3 inches of clearance between the

furnace combustion air openings in the front panel and

any closed panel or door provided?

5. Are the ventilation and combustion air openings large

enough and will they remain unobstructed? If outside

air is used, are the openings set above the highest snow

accumulation level? (See the Air for Combustion and

Ventilation section.)

6. Allow sufficient height in supply plenum above the

furnace to provide for cooling coil installation, if the

cooling coil is not installed at the time of this furnace

installation.