5

AM7A0C36H31-SF-1A

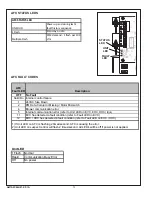

SUBCOOLING AdJUSTMENT

The following combinations should be charged to 8

degrees sub-cooling to maintain rated HSPF.

Indoor Unit Model No.

Outdoor Unit Model No.

*AM7A0C36H31SA

4A6B4036E1

4A6H5036E1

4TWB4036E1

4TWR5036E1

* May be “A” or “T”

All other non-rated matches must be charged per the

nameplate charging instructions.

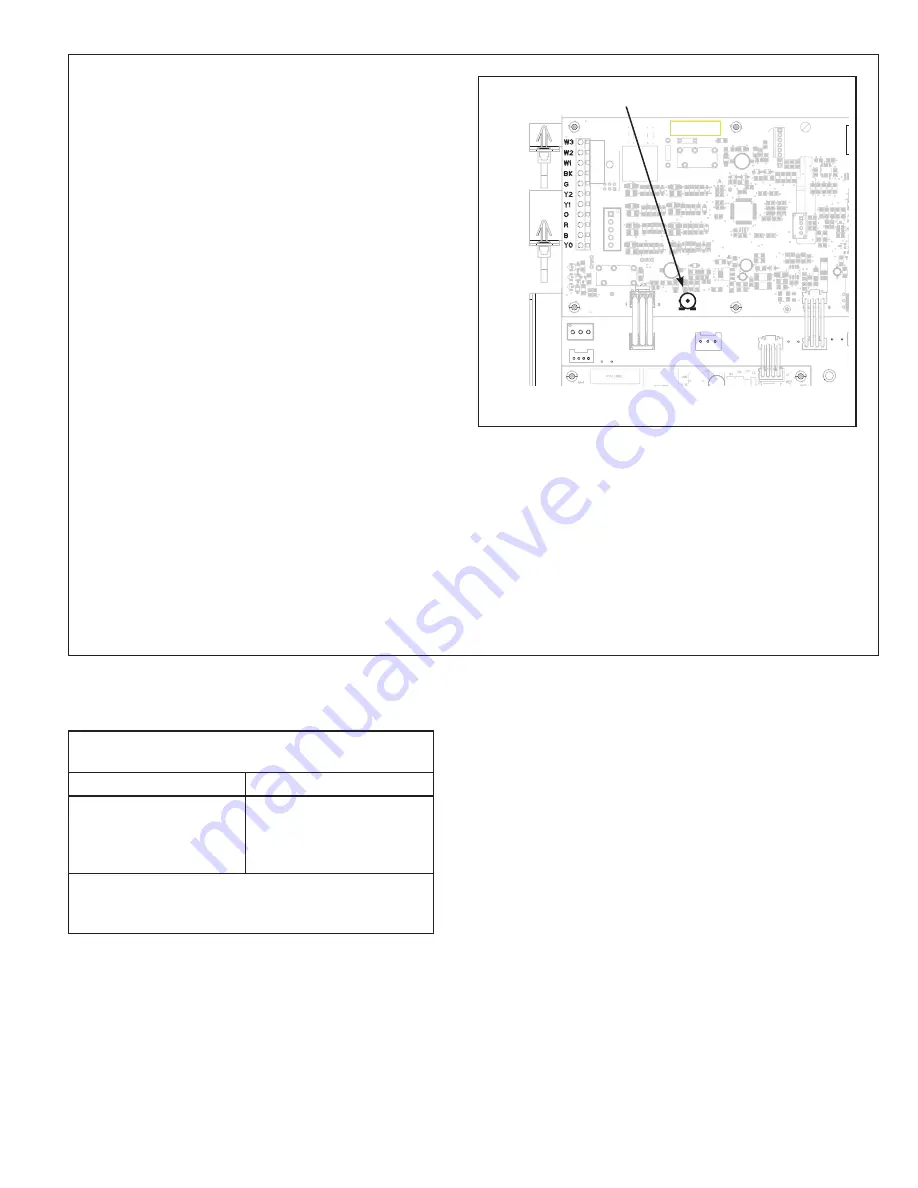

Unit Test Mode

Unit Test Mode will exit if any demand is given to the unit.

To enter Unit Test Mode:

1. Shut System Switch on comfort control to Off

2. Power cycle unit power, wait 5 seconds

3. Press and hold the Unit Test Button for 1-2 seconds

Sequence of Unit Test Mode

4. EVC drives the EEV motor to the 1st stage position for 5

seconds

5. EVC drives the EEV motor to the 2nd stage position for 5

seconds

6. AFC energizes the blower at 50% and then continues

to ramp until it reaches 100% cooling airflow. Humidifier

contacts close when the blower starts

7. EHC energizes the W1, W2, and W3 circuit relay(s) for 5

seconds in 5 second intervals

8. All relays de-energize and the blower shuts off after five

seconds.

If a fault occurs during the Unit Test Mode, the LED will flash

the code and continue the test

Fault Reporting

This unit stores the last four faults that have occurred. Each

device will report the last four faults after each power

cycle of the unit. See the Fault Table section in the

Service Facts for a list of fault codes

Clearing Faults

To clear the last four faults of all control boards, press and

hold the Unit Test Button for 10-12 seconds.

Pb

FAULT

UNIT

48

33

32

17

16

1

64

49

B K Jumper

TEST

TRANE U.S. INC.

VD

D

PG

D

MC

LR

VS

S

PG

C

3.3

V

SC

L

SD

A

GN

D

HUM

PART NO. LABEL

BAR CODE

1

2

3

4

5

STATUS

Yo Jumper

+13.8V

C60

C59

R57

R58

R64

R65

R76

R78

S3

R110

R41

R68

C40

R

93

R109

R12

R55

R23

R20

R49

R13

R14

D23

D19

D18

C46

C39

C6

C23

R80

R71

R67

R52

R75

R72

C41

R61

Q6

Q7

R1

R33

R34

J4

Q1

X1

U4

U3

TZ2

T2

T1

R99

R98

R97

R

60

R96

R95

R21

R91

R

87

R

88

R70

R86

R83

R81

R66

R79

R77

R54

R103

R106

R4

R104

R

51

R5

R47

R42

R39

R82

R37

R

35

R

31

R74

R89

R25

R18

R19

R10

R9

R8

R3

R2

R5

R7

Q8

MOV1

L2

L3

K1

J3

J6

J9

D36

D35

D1

D

22

D29

D

25

D24

D7

D4

D2

D28

C57

C54

C51

C49

C48

C47

C52

C43

C42

C36

C35

C

34

C31

C30

C29

C7

C3

C2

C1

U1

C58

R105

C50

U2

R24

R17

D6

D3

R NET

R NET 2

R73

1

J8

Yo

R

B

O

Y1

J1

W2

W1

R63

R62

R56

D21

D20

C32

C33

R38

R36

R16

R15

R32

R11

R28

R27

R26

D13

D12

D5

D11

D10

C24

C25

C4

C5

C16

C17

D8

R50

R45

R85

R84

D16

D15

D31

D30

C26

C27

C44

C45

D32

D33

R94

R100

R101

R

10

7

K2

R

6

C53

C

22

C

19

C

15

C

12

C

9

C

8

C

11

C

14

C

18

C

21

D26

R69

C37

C38

L1

R102

D27

R40

R46

R43

Q3

Q

1

1

HP

OU

Airflow Control (AFC)

Unit Test Button