15

Installation (Continued)

Refrigerant Piping

Refrigerant piping must be properly sized and applied.

These two factors have a very significant effect on both sys-

tem performance and reliability.

Note: Use Type "L" refrigerant grade copper tubing

only.

Refrigerant Piping should be sized and laid out according to

the job plans and specifications. This should be done when

the system components are selected. The primary objective

when sizing refrigerant piping for this unit is to make refrig-

erant line sizes as small as possible while avoiding exces-

sive refrigerant pressure drops.

Sizing refrigerant lines as small as possible minimizes the

required refrigerant charge and maximizes compressor life.

Trane recommends that the Refrigerant Line Sizing pro-

gram in the "Trane C.D.S. Application Toolbox" be used to

size the refrigerant lines. This program supersedes the line

sizing tables in both the Trane Reciprocating Refrigeration

publication and the Trane Air Conditioning Manual. If you do

not have access to this program, contact your local Trane

Commercial Sales office for assistance.

Liquid Lines

Basic sizing parameters with the system operating at full

load for liquid lines are:

Maximum Liquid velocity ...................................... 600 fpm

Maximum allowable pressure drop .................. 7 psig (1

F)

As the pressure drop in the liquid line increases, the poten-

tial for liquid flashing, due to reduced refrigerant pressure

corresponding to a reduced liquid temperature (subcooling),

increases. Under these conditions, liquid lines exposed to

high surrounding ambient temperatures must be insulated.

Note: Adding refrigerant to a system with

improperly sized refrigerant lines will only

decrease system performance and reliability and

accentuate poor operating condition.

Isolate all refrigerant lines from the building. This prevents

transferring line vibration to the structure. Do not secure the

lines rigidly to the building at any point since this will defeat

the isolation system of the unit.

Refer to the appropriate unit illustration in Figure 3-2 for re-

frigerant line size connections and locations. Connect the

liquid line piping to the stubs provided at the liquid line shut-

off valves.

Note: The installer must cut an appropriately-sized

opening in the unit sheet metal for the refrigerant

piping entrance into the unit.

Liquid Line Components

Filter driers and valves (expansion valves, charging valves,

etc.) should be provided in the liquid lines just before the

evaporator. Minimize the use of valves, reducers and tube

bends as much as possible to avoid excessive pressure

drop before the expansion valve.

Liquid Line Filter Drier

Install the filter driers (provided by the installer) in the liquid

lines as close as possible to the expansion valves. Locate

them upstream of the moisture indicator and solenoid

valves (Solenoid valves may not be applicable).

Liquid Line Moisture Indicators

To aid in troubleshooting, charging and servicing the sys-

tem, install moisture indicators in the liquid lines near the

evaporator, down stream of the liquid line drier between the

solenoid valve (if applicable) and the expansion valve.

Liquid Line Solenoid Valves

Liquid line solenoid valves are not recommended on units

when they are connected to DX coils. Liquid line solenoid

valves are recommended for refrigerant migration control

when they are connected to an EVP chiller and should be

connected as described in the “Electrical Wiring” section.

Note: Do not use any solenoid valve as a

pumpdown device. Equipment damage will occur.

Thermostatic Expansion Valve (TEV)

Trane recommends a balance-ported externally equalized

valve in order to maintain satisfactory superheat control

down to lower valve loading conditions and to compensate

for pressure drops between the expansion valve and super-

heat control point (evaporator refrigerant outlet). The power

head should be a “VGA” charge with Sporlan valves or a

“W” charge with Alco valves. These charges provide smooth

control at air conditioning conditions and are less suscep-

tible to power head “charge migration” than the conven-

tional gas charged types.

Discharge (Hot Gas) Lines

Discharge lines should be pitched downward 1/2 inch for

each 10 feet of horizontal run in the direction of hot gas flow

and away from the compressor. Insulate any portion of the

discharge piping that is exposed to outdoor ambient tem-

perature.

Discharge line sizing is based on the minimum velocity re-

quired to provide good oil movement through the system.

Basic discharge line parameters are:

Maximum allowable pressure drop .......................... 6 psig

Maximum velocity .............................................. 3500 fpm

Minimum velocities at Minimum Load:

Horizontal Lines ................................................ 500 fpm

Vertical Lines .............................. Refer to the Table 3-2

Summary of Contents for CAUC-C80

Page 8: ...8 Figure 3 2 CAUC C80 Unit Dimensional Data Recommended Clearances ...

Page 9: ...9 Figure 3 2 Continued CAUC D10 Unit Dimensional Data Recommended Clearances ...

Page 10: ...10 Figure 3 2 Continued CAUC D12 Unit Dimensional Data Recommended Clearances ...

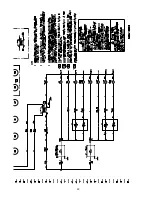

Page 19: ...19 Installation Continued Figure 3 5 Typical CAUC C80 through D12 Field Wiring Diagram ...

Page 28: ...28 Figure 5 2 Typical Wiring Schematic for 80 through 120 Ton Units ...

Page 29: ...29 ...

Page 30: ...30 Figure 5 3 Typical Control Panel Connections Diagram for 80 through 120 Ton Units ...

Page 31: ...31 ...

Page 36: ...36 ...