32

Service and Maintenance

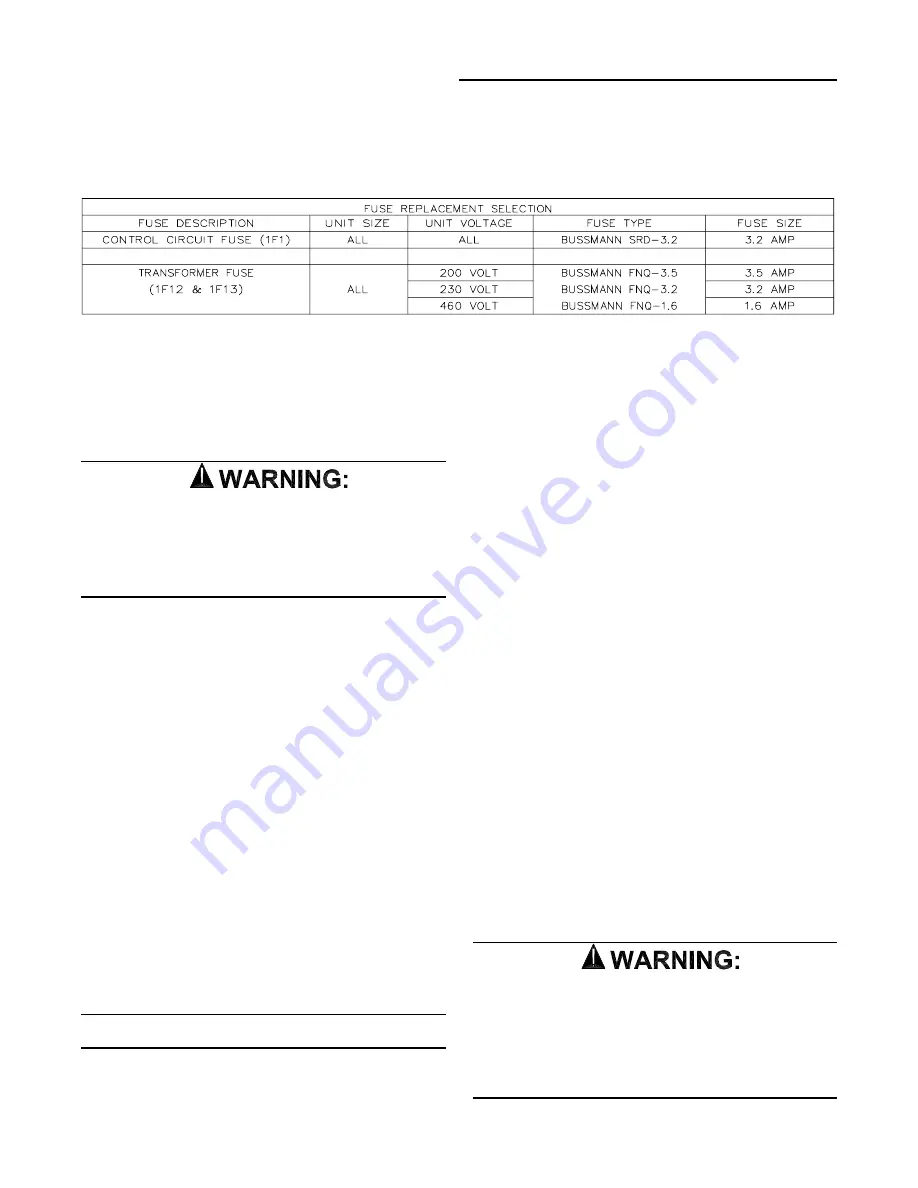

Fuse Replacement Data

Table 6-1 lists the replacement fuses for the control circuit

and Transformers.

Table 6-1

Fuse Replacement Data

Monthly Maintenance

Before completing the following checks, turn all system con-

trol circuit switches to the “Off” position. “Open” the main

power disconnect switches for the Condensing Unit and all

system support equipment. “lock” the disconnect switches

in the “Off” position before removing any access panels.

H A Z A R D O U S V O LTA G E !

DISCONNECT ALL ELECTRIC POWER INCLUDING

REMOTE DISCONNECTS BEFORE SERVICING.

Failure to disconnect power before servicing can

cause severe personal injury or death.

Air Handling Equipment

[ ] Inspect the return air filters. Clean or replace them if nec-

essary.

[ ] Check the evaporator drain pan and condensate piping

to ensure that there are no blockages.

[ ] Inspect the evaporator coils for dirt. If the coils appear

dirty, clean them according to the instructions described

in the “Coil Cleaning” section.

[ ] Inspect the economizer damper hinges and pins (if appli-

cable) to ensure that all moving parts are securely

mounted. Clean the blades as necessary.

[ ] Verify that all damper linkages move freely; lubricate with

white grease, if necessary.

[ ] Check Supply Fan motor bearings; repair or replace the

motor as necessary.

[ ] Check the fan shaft bearings for wear. Replace the bear-

ings as necessary.

[ ] Lubricate the supply fan bearings. Refer to the equip-

ment manufacturer for their recommended greases.

Note: Over lubrication can be just as harmful as not

enough grease.

Use a hand grease gun to lubricate these bearings; add

grease until a light bead appears all around the seal. Do

not over lubricate!

After greasing the bearings, check the setscrews to en-

sure that the shaft is held securely to the bearings and

Fan wheels. Make sure that all bearing supports are

tight.

[ ] Check the supply fan belt(s). If the belts are frayed or

worn, replace them.

[ ] Verify that all wire terminal connections are tight.

[ ] Generally inspect the unit for unusual conditions (e.g.,

loose access panels, leaking piping connections, etc.)

[ ] Make sure that all retaining screws are reinstalled in the

unit access panels once these checks are complete.

Condensing Unit

[ ] Manually rotate the condenser fans to ensure free move-

ment and check motor bearings for wear. Verify that all of

the fan mounting hardware is tight.

[ ] Verify that all wire terminal connections are tight.

[ ] Inspect the condenser coils for dirt and foreign debris. If

the coils appear dirty, clean them according to the in-

structions described in the “Coil Cleaning” section.

[ ] Inspect the compressor and condenser fan motor contac-

tors. If the contacts appear severely burned or pitted, re-

place the contactor. Do not clean the contacts.

[ ] Check the compressor oil level. (Compressors “Off”)

System operation

[ ] Close the main power disconnect switch for the Con-

densing Unit and all system support equipment. Turn all

system control circuit switches to the “On” position.

HAZ A R D O U S V O L TA G E

R O T A T I N G P A R T S !

UNIT STARTS AUTOMATICALLY

Make sure all personnel are standing clear of the unit

before proceeding. The system components will start

when the power is applied.

Summary of Contents for CAUC-C80

Page 8: ...8 Figure 3 2 CAUC C80 Unit Dimensional Data Recommended Clearances ...

Page 9: ...9 Figure 3 2 Continued CAUC D10 Unit Dimensional Data Recommended Clearances ...

Page 10: ...10 Figure 3 2 Continued CAUC D12 Unit Dimensional Data Recommended Clearances ...

Page 19: ...19 Installation Continued Figure 3 5 Typical CAUC C80 through D12 Field Wiring Diagram ...

Page 28: ...28 Figure 5 2 Typical Wiring Schematic for 80 through 120 Ton Units ...

Page 29: ...29 ...

Page 30: ...30 Figure 5 3 Typical Control Panel Connections Diagram for 80 through 120 Ton Units ...

Page 31: ...31 ...

Page 36: ...36 ...