27

CG-PRC012-EN

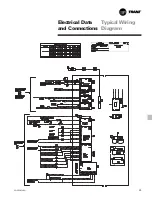

Electrical Data

and Connections

Table E-1. Electrical data for CGWF water-cooled chillers

Unit Wiring Data

Compressor

Controls

Unit

Rated

Minimum

Maximum

Recommended

RLA

LRA

Size

Voltage

Circuit Ampacity

Fuse Size

Dual Element Fuse Size

Quantity

Each

Each

kW

208-230/60

77

110

100

34

251

0.16

380/60

38

50

50

2-10

17

142

0.16

20

460/60

32

45

40

14

117

0.16

575/60

27

40

40

12

94

0.16

400/50

32

50

50

14

110

0.16

208-230/60

99

150

125

52/34

376/251

0.16

380/60

51

70

70

1-10

27/17

215/142

0.16

25

460/60

43

60

60

1-15

23/14

178/117

0.16

575/60

35

50

45

18/12

143/94

0.16

400/50

42

50

45

22/14

174/110

0.16

208-230/60

117

150

150

52

376

0.16

380/60

61

80

80

2-15

27

215

0.16

30

460/60

52

70

70

23

178

0.16

575/60

41

50

50

18

143

0.16

400/50

50

80

80

22

174

0.16

208-230/60

145

175

175

34

251

0.24

380/60

72

80

90

4-10

17

142

0.24

40

460/60

60

70

70

14

117

0.24

575/60

51

60

70

12

94

0.24

400/50

60

90

90

14

110

0.24

208-230/60

185

225

225

52/34

376/251

0.24

380/60

95

110

110

2-10

27/17

215/142

0.24

50

460/60

80

100

100

2-15

23/14

178/117

0.24

575/60

65

80

80

18/12

143/94

0.24

400/50

78

110

125

22/14

174/110

0.24

208-230/60

221

250

250

52

376

0.24

380/60

115

125

150

4-15

27

215

0.24

60

460/60

98

110

110

23

178

0.24

575/60

77

90

90

18

143

0.24

400/50

94

125

150

22

174

0.24

Table E-2. Electrical data for high temperature condenser CGWF chillers and CCAF compressor chillers

Unit Wiring Data

Compressor

Controls

Unit

Rated

Minimum

Maximum

Recommended

RLA

LRA

Size

Voltage

Circuit Ampacity

Fuse Size

Dual Element Fuse Size

Quantity

Each

Each

kW

208-230/60

88

125

110

39

251

0.16

20

380/60

45

60

60

2-10

20

142

0.16

460/60

38

50

50

17

117

0.16

575/60

32

45

40

14

94

0.16

400/50

38

50

50

17

117

0.16

208-230/60

112

150

150

58/39

376/251

0.16

25

380/60

59

80

80

1-10

31/20

215/142

0.16

460/60

50

70

70

1-15

26/17

178/117

0.16

575/60

40

60

60

21/14

143/94

0.16

400/50

48

70

70

25/17

178/117

0.16

208-230/60

131

175

175

58

376

0.16

30

380/60

70

100

90

2-15

31

215

0.16

460/60

59

80

80

26

178

0.16

575/60

47

60

60

21

143

0.16

400/50

56

80

80

25

178

0.16

208-230/60

166

200

200

39

251

0.24

40

380/60

85

100

100

4-10

20

142

0.24

460/60

72

80

90

17

117

0.24

575/60

60

70

70

14

94

0.24

400/50

72

80

90

17

117

0.24

208-230/60

209

250

250

58/39

376/251

0.24

50

380/60

110

125

150

2-10

31/20

215/142

0.24

460/60

93

110

110

2-15

26/17

178/117

0.24

575/60

75

90

90

21/14

143/94

0.24

400/50

90

110

110

25/17

178/117

0.24

208-230/60

247

300

300

58

376

0.24

60

380/60

132

150

150

4-15

31

215

0.24

460/60

111

125

125

26

178

0.24

575/60

89

110

100

21

143

0.24

400/50

106

125

125

25

178

0.24

Notes:

1. Minimum circuit ampacity is 125% of the largest compressor RLA, plus 100% of the remaining compressor(s) RLA, per NEC 440-32 and NEC 440-33.

2. Maximum fuse size is 225% of the largest compressor RLA, plus 100% of the remaining compressor(s) RLA, per NEC 440-33.

3. Recommended dual element fuse size is 175% of the largest compressor RLA, plus 100% of remaining compressor(s) RLA, per NEC 440-33.

4. Use copper conductors only.

5. Voltage Utilization Range: Rated Voltage

Utilization Range

208-230/60

188-253

380/60

342-418

460/60

414-506

575/60

517-633

400/50

360-440

6. Local codes may take precedence.

7. If unit is ordered with the High Condenser Entering Water Temperature Range (90-130), use CCAF electrical information.

Summary of Contents for CCAF

Page 28: ...CG PRC012 EN 28 Electrical Data and Connections Typical Wiring Diagram ...

Page 29: ...29 CG PRC012 EN Electrical Data and Connections Typical Wiring Diagram ...

Page 30: ...CG PRC012 EN 30 Electrical Data and Connections Field Layout ...

Page 31: ...31 CG PRC012 EN Electrical Data and Connections Field Layout ...

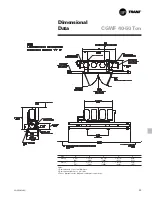

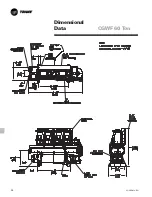

Page 34: ...CG PRC012 EN 34 CGWF 60 Ton Dimensional Data ...