Following two methods for determining the tensioning are described:

Force-way measurement

The information

-

Test force FE

-

Indentation depth TE

-

Statistical belt tension (belt tension), FS

The belts are to be tensioned so that the deflection TE is when the belt is loaded with the test

load in point FE (such as with a spring balance). Alternatively, you can check the static belt

tension FS directly with special belt tension measuring instruments.

Frequency Measurement

Special measuring instruments that are based on frequency measurements are available on

the market. Tension the belt so, that during the measurement you measure the same fre-

quency as indicated on the fan data sheet.

9.2.5 Replacing of belts

-

Loosen the belt tension so far that the old belt can be removed.

-

Cleaned before putting the new belt pulleys and check for damage and wear.

-

Never push the new belt with a tool on the pulley, to avoid damage which shorten the

lifetime.

-

On multi-groove pulleys all belts must be replaced simultaneously.

-

Ensure that the belt number coincides with the number of pulley grooves.

-

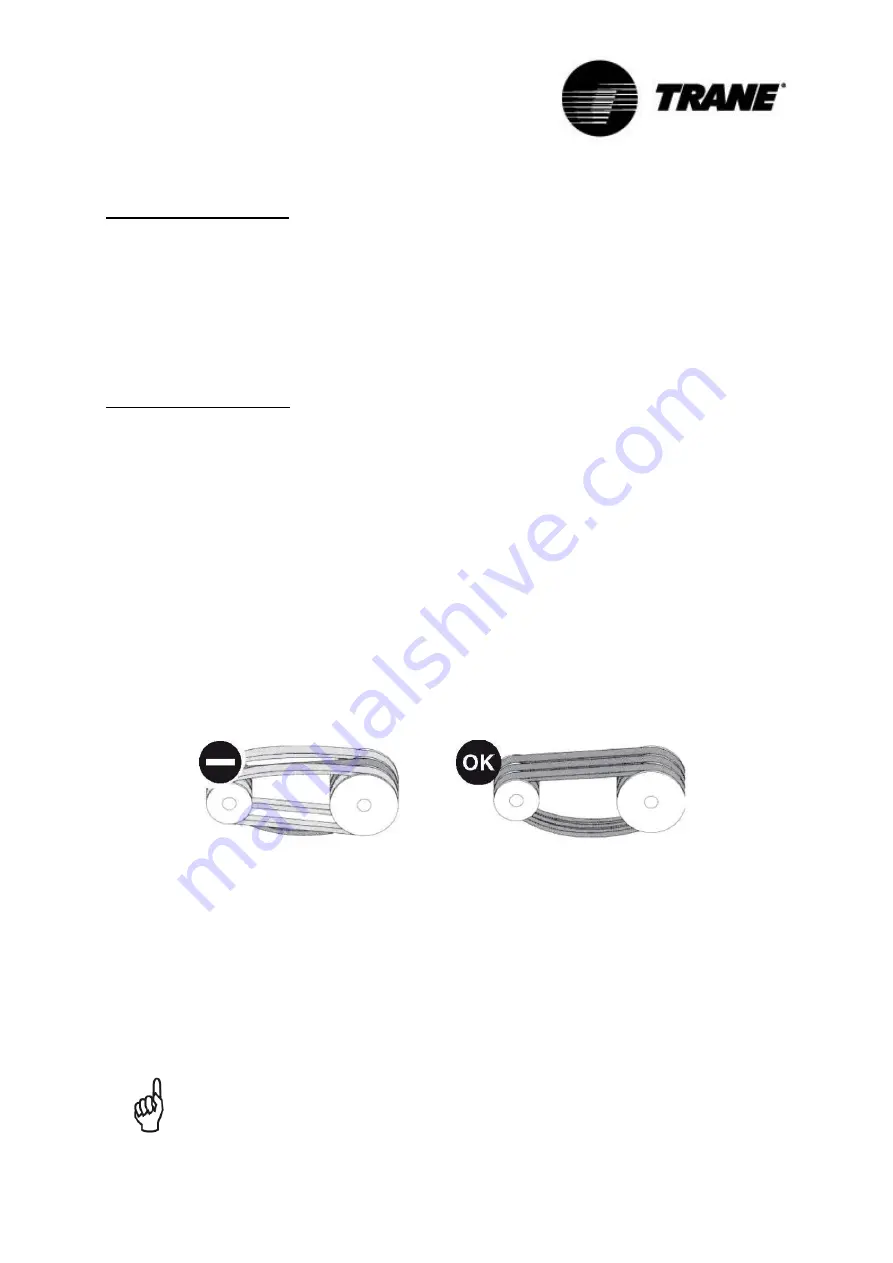

When tensioning the belt on multi-groove drives, ensure that all belts have their loose

side on the same side otherwise they can be damaged see

Figure 137:

Multi-groove pulleys

– attaching the belts

-

Tension the belts, turn the drive a few turns with no load and re-measure the belt tension.

-

Check axle and wheel alignment, see

chapter 9.2.4 (Re-tensioning of belts).

-

Repeat these steps until alignment and belt tension are correct.

9.3 Air filters

To ensure the performance and the energy-efficient operation of the air han-

dling unit, the air filters must be replaced regularly.

Summary of Contents for CCEB

Page 48: ...Figure 83 Pulling out the filters Figure 84 Pull out tool...

Page 74: ......