51

Troubleshooting

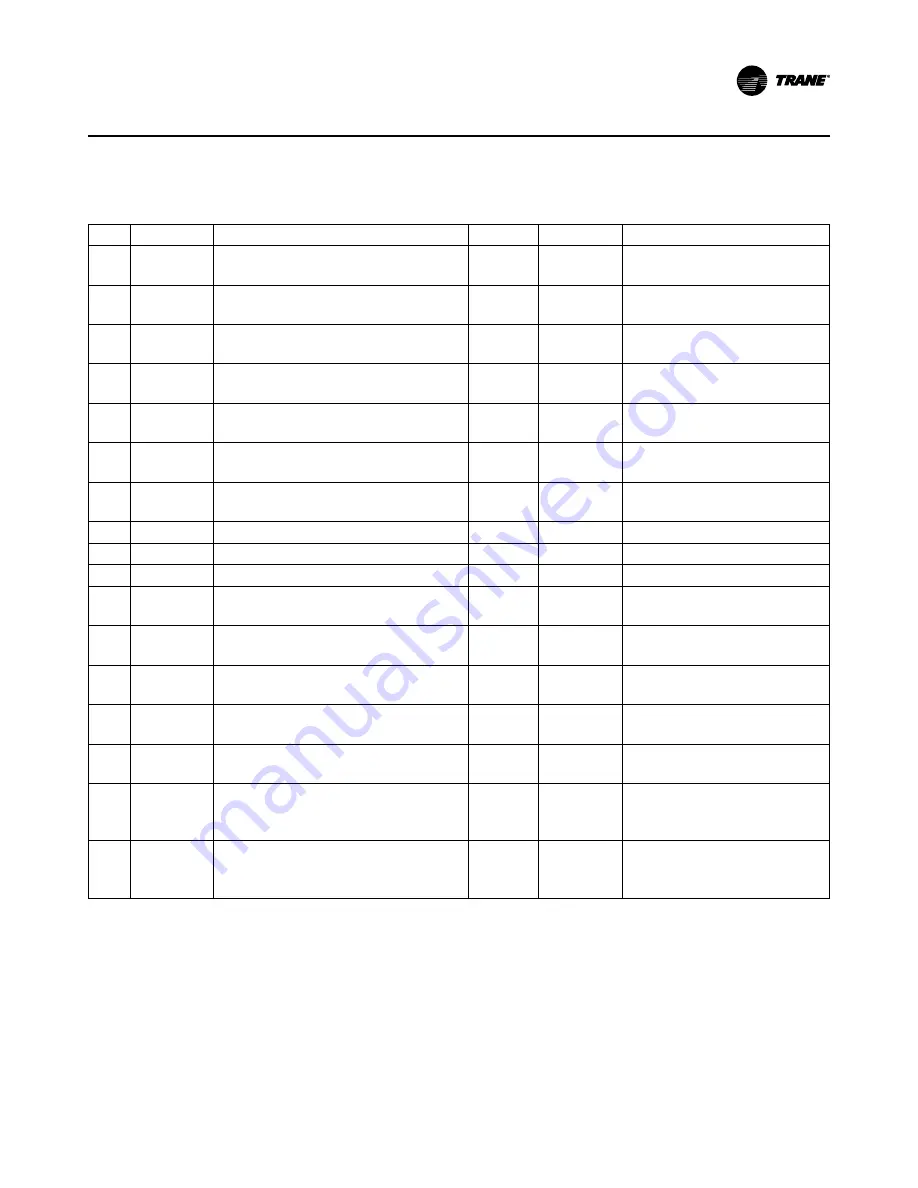

17 fault input alarm switches, 1 fault output alarm switch and 1 operating status output switch are arranged for the

double-compressor system.

No.

Input Port

Fault Description

Type

Code

Fault Handling

1

TH1

Short circuit / open circuit of water inlet

temperature sensor

A

SE

Turn off all external devices

2

TH2

Short circuit / open circuit of water

outlet temperature sensor

A

SL

Turn off all external devices

3

TH3

Short circuit / open circuit of suction

temperature sensor 1

A

Sd

Turn off all external devices

4

TH4

Short circuit / open circuit of defrosting

temperature sensing sensor 1

A

S1

Turn off all external devices

5

TH5

Short circuit / open circuit of defrosting

temperature sensing sensor 2

A

S2

Turn off all external devices

6

TH6

Short circuit / open circuit of suction

temperature sensor 2

A

S3

Turn off all external devices

7

OVHT/HP2

High pressure alarm of compressor 2

E

H2

Only switch off the compressor

2

8

FLOW

Lack of water flow

D

FL

Turn off all external devices

9

OV-PUMP

Overload of water pump 1

B

OP

Turn off all external devices

10

OV-FAN

Overload of fan

B

OF

Turn off all external devices

11

OV-COMP1

Overload of compressor 1

C

C1

Only switch off the compressor

1

12

OV-COMP2

Overload of compressor 2

E

C2

Only switch off the compressor

2

13

HP1

High pressure voltage of compressor 1

C

H1

Only switch off the compressor

1

14

LP1

Low pressure voltage of compressor 1

C

L1

Only switch off the compressor

1

15

FREZ/LP2

Low pressure voltage of compressor 2

E

L2

Only switch off the compressor

2

16

/ / /

Low refrigeration water outlet

temperature

D

E3

Switch off the compressor. The

auxiliary heater for the water

pump operates.

17

/ / /

Low suction temperature

D

E4

Switch off the compressor. The

auxiliary heater for the water

pump operates.