CG-PRC026C-GB

29

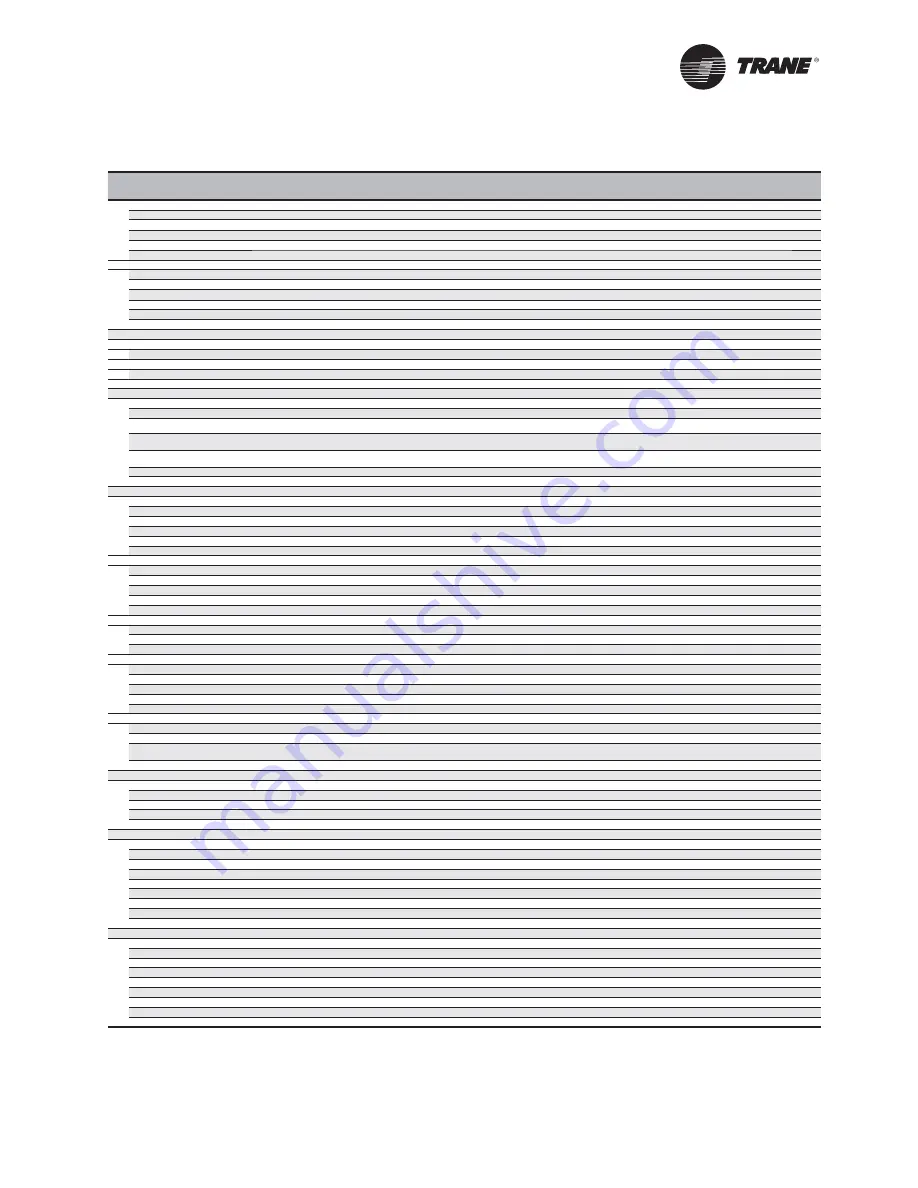

General Data

Table

8

- CXAX High Effi ciency and Low Noise (continued)

Eurovent Performances (1)

CXAX

015

HE-LN

CXAX

017

HE-LN

CXAX

020

HE-LN

CXAX

023

HE-LN

CXAX

026

HE-LN

CXAX

030

HE-LN

CXAX

036

HE-LN

Net Cooling Capacity

(kW)

108

118

94

114

127

146

162

Total Power input in cooling

(kW)

36

41

34

37

43

49

55

EER

3.00

2.88

2.81

3.06

2.96

2.95

2.93

ESEER

4.20

4.02

3.98

4.10

4.00

4.03

3.95

Eurovent Ef

fi

ciency class Cooling

B

C

C

B

B

B

B

Sound power level

(dBA)

81

82

81

84

83

83

84

Heating application data (2)

Net Heating Capacity

(kW)

110

120

101

114

127

139

162

Total Power input in heating

(kW)

35

39

32

37

42

46

52

COP

3.14

3.12

3.16

3.08

3.02

3.00

3.11

Eurovent Ef

fi

ciency class Heating

B

B

B

B

B

B

B

η

s

(%)

133

132

131

124

124

128

129

SCOP

3.39

3.37

3.35

3.16

3.16

3.28

3.30

Unit amps (4) (5)

Unit rated amps

(A)

86

98

78

93

104

114

131

Unit rated amps - HESP

(A)

86

98

78

93

104

114

131

Unit start up amps

(A)

218

224

200

215

236

247

256

Unit start up amps - HESP

(A)

218

224

200

215

236

247

256

Short Circuit Unit Capacity (9)

(kA)

15

15

15

15

15

15

15

Compressor

Compressor Number per Circuit

#

3

3

2

2

2

2

2

Type

Scroll

Scroll

Scroll

Scroll

Scroll

Scroll

Scroll

Model Circuit1 / Circuit 2

13+13+13

15+15+15

7.5+10 /

7.5+10

10+10 / 10+10 10+13 /10+13 13+13 / 13+13 15+15 / 15+15

Rated Amps Circuit1 / Circuit 2 (4)

(A)

25.3+25.3+

25.3

29.5+29.5+

29.5

15.5 / 20.2 /

15.5+20.2

20.2 / 20.2 /

20.2+20.2

20.2 / 25.3 /

20.2+25.3

25.3 / 25.3 /

25.3+25.3

29.5 / 29.5 /

29.5+29.5

Locked Rotor Amps Circuit1 / Circuit 2 (4)

(A)

158+158 +158 155+155 +155

98 / 142 /

98+142

142 / 142 /

142+142

142 / 158 /

142+158

158 / 158 /

158+158

155 / 155 /

155+155

Motor RPM

(rpm)

2900

Oil sump heater Circuit1 / Circuit 2

(W)

0.25 / 0

0.25 / 0

0.17 / 0.17

0.17 / 0.17

0.17 / 0.17

0.17 / 0.17

0.17 / 0.17

Evaporator

Quantity

#

1

1

1

1

1

1

1

Type

Stainless steel Copper Brazed plate Heat exchanger

Evaporator model

P120Tx110

P120Tx110

DP300x82

DP300x82

DP300x82

DP300x114

DP300x114

Evaporator Water Content volume

(l)

13.3

13.3

8.5

8.5

8.5

11.8

11.8

Nominal water connection size (Grooved coupling) - Without HYM (in) - (mm)

2” - 60.3

2” - 60.3

3” OD - 76.1

3” OD - 76.1

3” OD - 76.1

3” OD - 76.1

3” OD - 76.1

Nominal water connection size (Grooved coupling) - With HYM

(in) - (mm)

3” OD - 76.1

3” OD - 76.1

3” OD - 76.1

3” OD - 76.1

3” OD - 76.1

3” OD - 76.1

3” OD - 76.1

Hydraulic Module Components

Expansion Tank Volume

(l)

35

35

35

35

35

35

35

Max User water loop Volume for factory mounted expansion tank (1)

(l)

2000

2000

2000

2000

2000

2000

2000

Optional water Buffer tank volume

(l)

444

444

444

444

444

444

444

Max. Water-side Operating Pressure without pump package

(kPa)

1000

Max. Water-side Operating Pressure with pump package

(kPa)

400

Condenser

Type

Aluminum

fi

ns & copper tubes heat exchanger

Quantity of coil

#

2

2

2

2

2

2

2

Face area per circuit

(m²)

5.93

5.93

2.96

2.96

2.96

2.96

3.46

Condenser Fan

Quantity

#

3

3

2

4

4

4

4

Diameter

(mm)

800

Fan / motor Type

Propeller fan : Variable speed - EC motor

Air

fl

ow per Fan

(m

3

/h)

13823

13828

14960

14964

12725

12725

13351

Motor RPM

(rpm)

150 - 686 RPM

Partial Heat recovery (PHR) option

Heat-Exchanger Type

Stainless steel Copper Brazed plate Heat exchanger

Heat-Exchanger Model

B3-027-20-4.5L

B3-027-20-4.5L 2x B3-014-14-4.5M 2x B3-014-14-4.5M 2x B3-014-14-4.5M 2x B3-027-14-4.5L 2x B3-027-14-4.5L

Water connection size (Thread connection)

(in) - (mm)

G 1”1/4

(31.75 mm)

G 1”1/4

(31.75 mm)

G 1”1/4

(31.75 mm)

G 1”1/4

(31.75 mm)

G 1”1/4

(31.75 mm)

G 1”1/4

(31.75 mm)

G 1”1/4

(31.75 mm)

Water content volume

(l)

0.5

0.5

2x0.14

2x0.14

2x0.14

2x0.35

2x0.35

Dimensions

Unit Length

(mm)

2327

2327

2327

2327

2327

2327

2327

Unit Width

(mm)

2250

2250

2250

2250

2250

2250

2250

Unit Height

(mm)

1747

1747

1747

1747

1747

1747

1947

Option Additional height

Water Buffer tank option

(mm)

+330

+330

+330

+330

+330

+330

+330

Weights

Shipping Weight (5)

(kg)

954

972

1000

1098

1098

1120

1190

Operating Weight (5)

(kg)

925

942

974

1072

1072

1093

1163

Option Additional shipping weight

Single pump - Standard head pressure

(kg)

47

47

45

47

47

47

47

Single pump - High head pressure

(kg)

49

49

49

49

49

49

49

Twin pump - Standard head pressure

(kg)

75

75

75

75

75

75

75

Twin pump - High head pressure

(kg)

86

86

84

84

84

84

84

Partial heat recovery option

(kg)

4.6

4.6

2x1.48

2x1.48

2x1.48

2x3.82

2x3.82

Water Buffer tank option

(kg)

425

425

425

425

425

425

425

System data

Nb of refrigerant circuit

#

1

1

2

2

2

2

2

Minimum cooling load % (6)

%

33

33

22

25

22

25

25

Standard unit

R410A refrigerant charge Circuit1 / Circuit 2

(kg)

26.0

26.0

13.0 / 13.0

13.5 / 13.5

13.0 / 13.0

13.5 / 13.5

14.5 / 14.5

Oil charge Circuit1 / Circuit 2

(l)

10.5

11.5

6.3 / 6.3

6.6 / 6.6

6.6 / 6.6

6.6 / 6.6

7.2 / 7.2

Unit with partial heat receovery option

R410a refrigerant charge Circuit1 / Circuit 2

(kg)

26.0

26.0

13.0 / 13.0

13.5 / 13.5

13.0 / 13.0

13.5 / 13.5

14.5 / 14.5

Oil charge Circuit1 / Circuit 2

(l)

10.5

11.5

6.3 / 6.3

6.6 / 6.6

6.6 / 6.6

6.6 / 6.6

7.2 / 7.2

POE Oil type

OIL058E / OIL057E

(1) At Evaporator water temperature : 12°C / 7°C - Condenser air temperature 35°C according to EN14511:2013

(2) At Evaporator water temperature : 40°C / 45°C - Condenser air. DB/WB 7°C/6°C according to EN14511:2013

(4) under 400V/3/50Hz

(5) Rated Condition without Pump Package

(6) Minimum ambient in heating operation is for unit at 40°C / 45°C

(7) Minimum start-up/operation ambient based on a 2.22 m/s (5mph) wind across the condenser.

(8) Maximum ambient operation is for unit at 12°C / 7°C

(9) If the power line of the unit is protected by fuses gG of the same size as the disconnect switch.

Electrical & system data are subject to change without notice. Please refer to unit nameplate data.