36

4

UNT-PRC002-GB

Technical Data

FWD

08

12

20

30

45

Power supply

(V/Ph/Hz)

230/1/50

Capacities

Cooling capacity on water (1)

(kW)

5,2

8,3

15

18,8

30,1

Heating capacity on water (2)

(kW)

6,3

11,9

18,9

20,9

38,2

Fan motor

(type)

2 x direct drive centrifugal

Fan power input (3)

(kW)

0,23

0,46

0,65

1,04

1,51

Current amps (3)

(A)

1,1

2,2

3,1

4,7

5,5

Start-up amps

(A)

3,2

5,5

9,3

14,1

16,5

Air flow

minimum

(m

3

/h)

490

980

1400

1800

2700

nominal

(m

3

/h)

820

1650

2300

3000

4500

maximum

(m

3

/h)

980

1970

2600

3600

5400

Main coil

Water entering/leaving connections

(type)

ISO R7 rotating female

(Dia)

3/4"

3/4"

1 1/2"

1 1/2"

1 1/2"

Electric heater (accessory for blower only)

Electric power supply

(V/Ph/Hz)

230/1/50

230/1/50 or 400/3/50

400/3/50

400/3/50

400/3/50

Heating capacity

(kW)

2/4

8

10

12

12

Hot water coil (accessory for blower only)

Heating capacity (4)

(kW)

6,3

12

17,4

22,4

34,5

G2 filter (filter box accessory)

Quantity

2

2

2

2

2

Dimensions ( LxWxth)

(mm)

386x221x8

486x271x8

586x321x8

586*421*8

586*621*8

G4 filter (filter box accessory)

Quantity

-

2

2

2

2

Dimensions ( LxWxth)

(mm)

-

486x264x48

586x314x48

586*414*48

586*614*48

Condensate pump (accessory)

(type)

Centrifugal

Water flow - lift height

(l/h - mm)

24 - 500

Not available for FWD30 and FWD45

Sound level (L/M/H speed)

Sound pressure level (5)

(dB(A))

36/40/43

38/41/44

46/50/53

47/52/57

47/52/58

Sound power level (5)

(dB(A))

46/50/53

48/51/54

56/60/63

57/62/67

57/62/68

Unit dimensions

Width x Depth

(mm)

890 x 600

1090 x 710

1290 x 820

1290 x 970

1290 x 1090

Height

(mm)

250

300

350

450

650

Shipped unit dimensions

Width x Depth

(mm)

933 x 644

1133 x 754

1333 x 864

1333 x 1008

1333*1133

Height

(mm)

260

310

360

460

660

Weight

(kg)

32

46

61

76

118

Colour

galvanised steel

Recommended fuse size

Unit alone (aM/gI)

(A)

8/16

8/16

8/16

8/25

8/25

Unit with electric heater (gI)

(A)

16 (2kW),25 (4kW)

40 (230V),3*16 (400V)

3*20

3*25

3*25

(1) Conditions: Water entering/leaving temperature: 7/12 °C, Air inlet temperature 27/19°C DB/WB - Nominal air flow

(2) Conditions: Water entering/leaving temperature: 50/45 °C, Air inlet temperature 20°C DB - Nominal air flow

(3) At high speed with nominal air flow.

(4) Water entering/leaving temperature 90/70 °C, air inlet temperature 20 °C DB, Nominal air flow.

(5) A rectangular glass wool duct 1m50 long is placed on the blower.The measurement is taken in the room containing the blower unit.

Heat exchanger operating limits:

FWD:

*water temperature: max 100° C

*absolute service pressure: min 1 bar/max 11 bars

Accessories - Hot water coil:

*water temperature: min. +2° C/max. 100° C

*absolute service pressure: min 1 bar/max 11 bars

AH-SVX03C-GB

Air washers

• Check that the fresh water supply is working correctly and that the water level is correct. Adjust as necessary.

• Depending upon the extent of water contamination, the degree of hardness and water treatment, any scale

deposits or other impurities must be cleaned off from the air washers. Any severe calcium deposits on components

such as spray pipes, droplet separators or strainers indicate that the treatment is inadequate.

• Deposits on spray pipes, strainers, air strengtheners and droplet separators may be treated with diluted formic

acid and subsequently rinsed off with clear water. In the case of droplet eliminators or air straightener blades of

plastic construction, any deposits may be occasionally removed by carefully flexing the components i.e. after they

have been dried off and removed from the module. Corroded or damaged droplet separator blades should be

replaced.

• Any strainers or sediment accumulations should be inspected and cleaned as necessary. Dismantle spray pipes

and clean. Check the fresh water feed, the overflow, siphon and the water tank for any sediment accumulation and

clean as necessary.

• Any spray pipes with erosion damage should be replaced.

• Never ream out spray pipe nozzles with sharp instruments. Flush out the spray pipe with a high pressure water jet,

with the spray pipe nozzles removed.

• Check that the setting of the sediment flushing valve (bleed-off) is correct.

Evaporative (Honeycomb) humidifier

Follow the instructions given in the Air Washers section. Any Honeycomb module strongly encrusted with calcium

deposits should be replaced. In the case of lightly contaminated components, with the air handling unit powered

off, add a suitable decalcifying agent to the circulating water and operate the pump until the deposits are dissolved.

Thoroughly wash off and flush through the system following this operation.

Trane cannot be held responsible for improper cleaning of the Honeycomb humidifiers. In order to avoid any excess

clogging of the honey comb humidifiers, it is recommended to interlock the spray pipe operation with the fan

operation.

Other humidification

For humidification with or without steam generator, atomizing nozzles or feeding cabinet, it is mandatory to follow

the manufacturer's instructions.

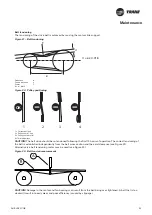

Dampers

Check for dirt and deposits, for any damage or signs of corrosion. Clean with pressurized air or steam. Check the easy

movement and correct operation of the dampers. If there is any tendency to jam, check the unit is not misleveled.

CAUTION!

Check that the linkage is firmly in place and tighten the screws if necessary.

Sound attenuators

Check for any dust deposits and clean with a vacuum cleaner as needed.

Weather louvers and hoods

Check for dirt and deposits, for any damage or signs of corrosion. Remove any leaves or foreign matter which may

have been drawn in.

Maintenance